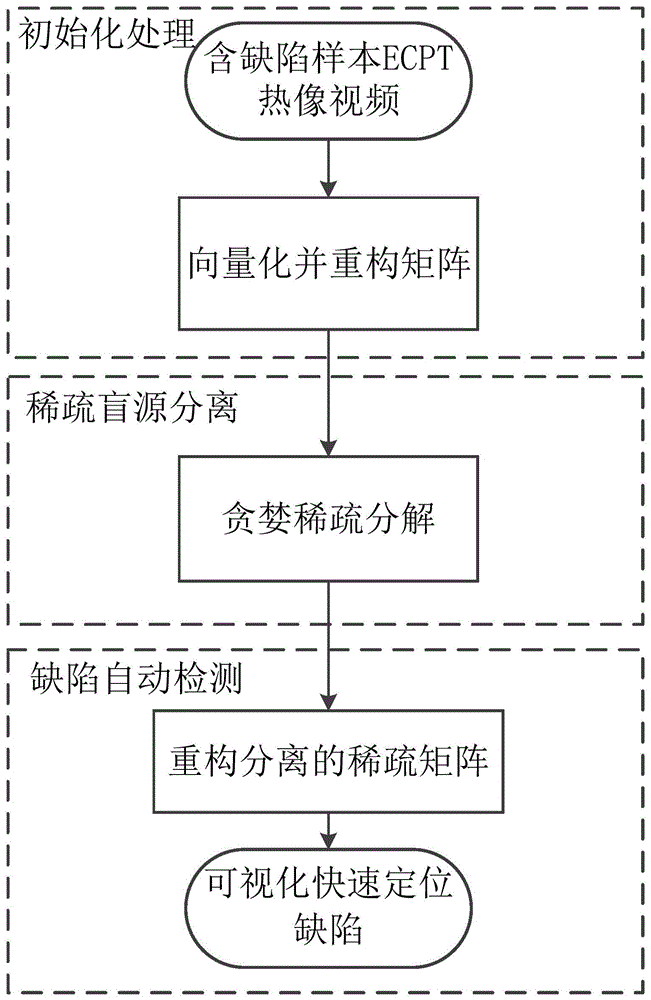

Greedy sparse decomposition-based ECPT defect rapid detection method

A technology of sparse decomposition and detection method, applied in the direction of material defect testing, etc., can solve the problem of wrong number of defects, defect quantification accuracy needs to be improved, loss of data information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

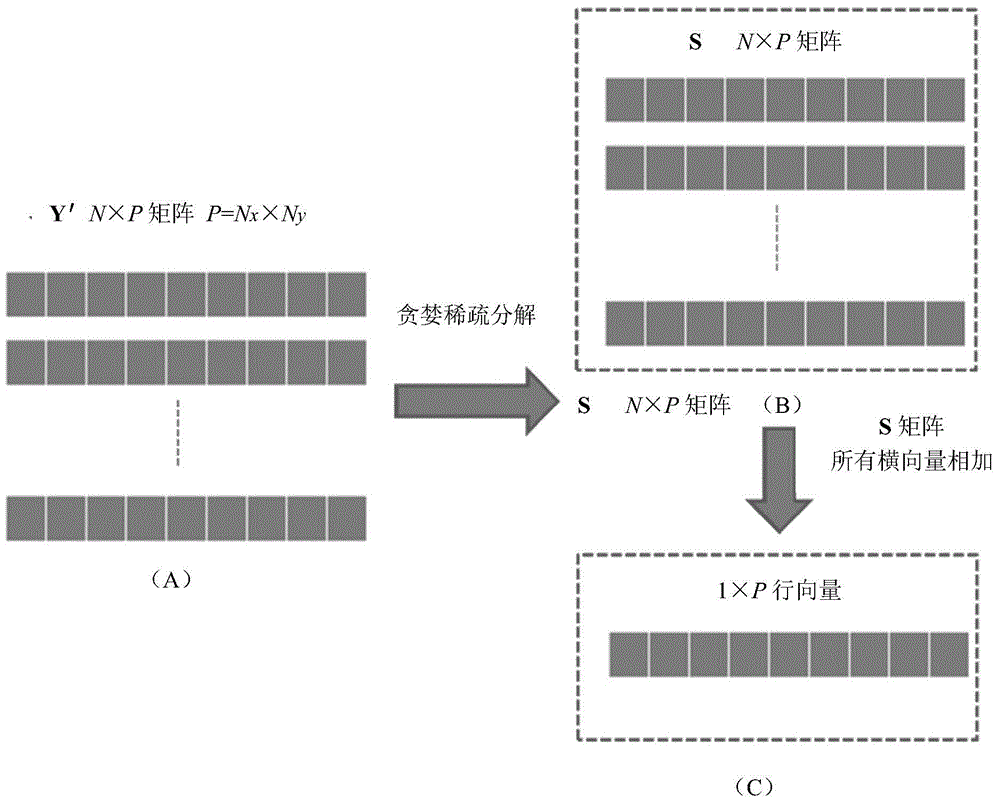

Method used

Image

Examples

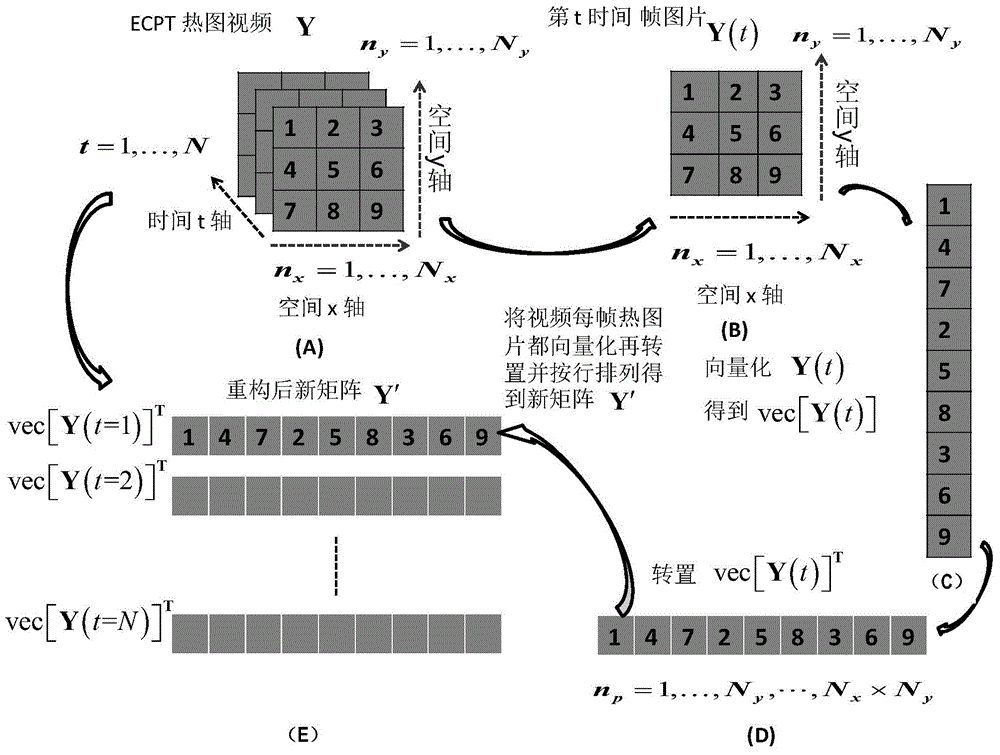

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

[0017] When there are defects (such as cracks) in the conductor material, under the action of ECPT, the eddy current distribution at the defect position is different under electromagnetic induction. When the eddy current path is at a defect (such as a crack), the path of the eddy current will change accordingly to form various distribution areas of different eddy current densities near the crack. The eddy current density concentration area will be formed at both ends of the crack, and the eddy current density dispersion area will be formed on both sides of the crack. Due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com