Building damage evaluation method based on simplified cantilever beam

A technology for cantilever beams and buildings, applied in the field of frame structure quality assessment in buildings, can solve the problems of rough data, heavy detection workload, inability to accurately determine structural damage, etc., and achieve the effect of obvious display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

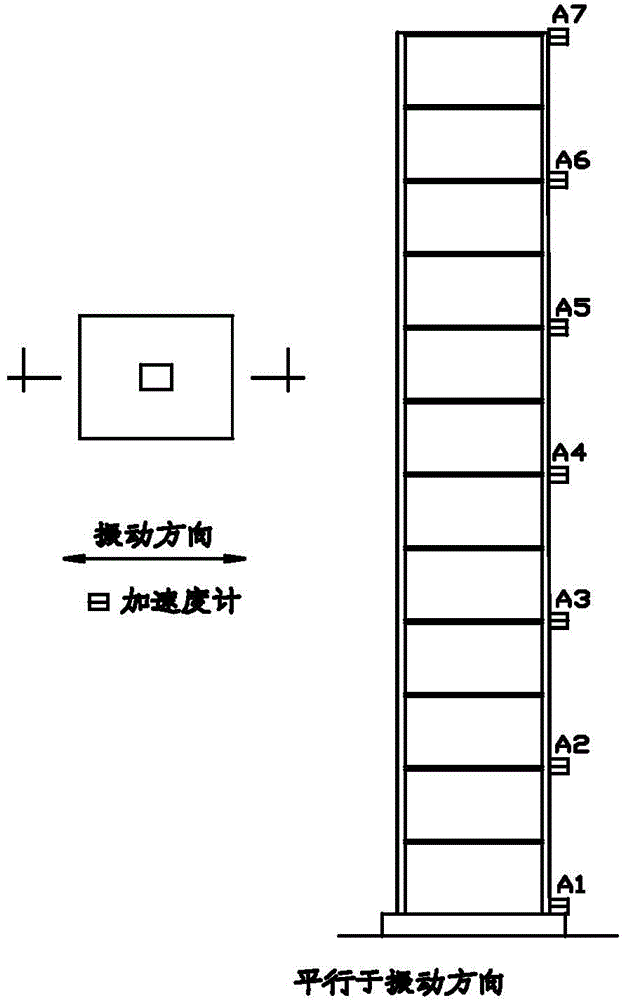

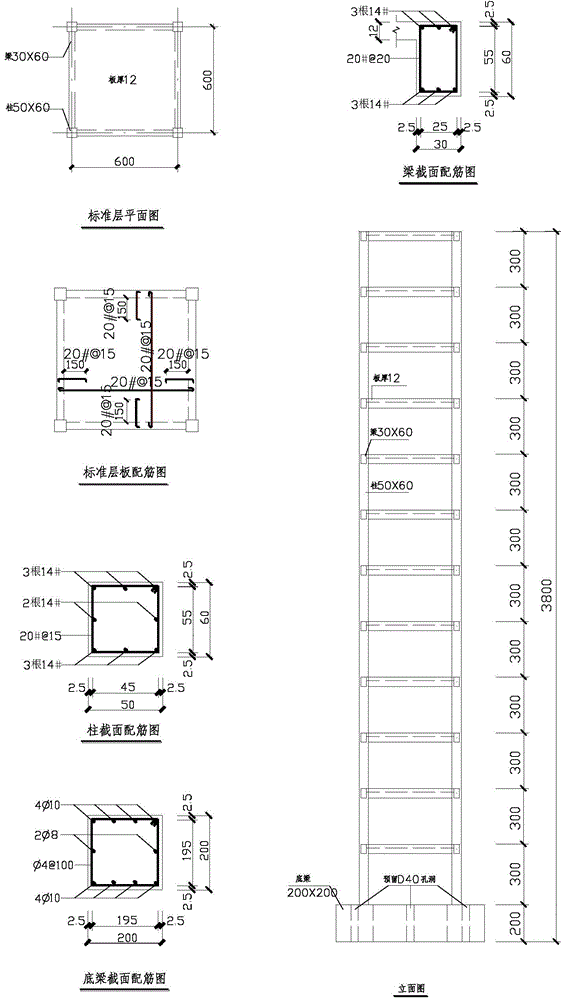

[0043] In the following, the method of the present invention is verified through the measured data of two reinforced concrete simply supported beams and the measured data of a shaking table test, and the damage degree is evaluated by using the obtained SVI index value.

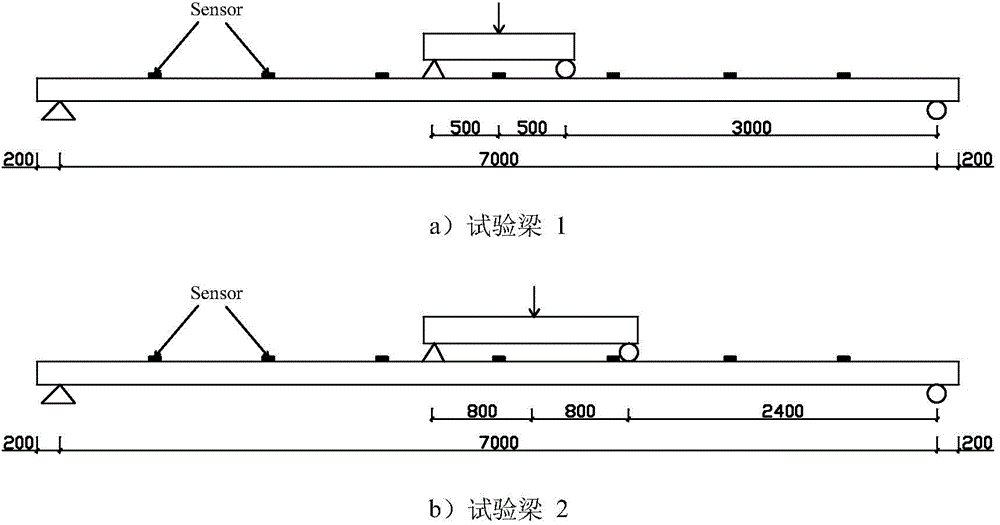

[0044] 1. Data analysis of simply supported beam test

[0045] First, a simple analysis of the test data of two reinforced concrete simply supported beams in the Key Laboratory of Structural Engineering and Vibration of the Ministry of Education of Tsinghua University was conducted to verify the preliminary characteristics of the improved direct stiffness method for damage identification. The span of the reinforced concrete beam is 7m, the section size is 250mm×500mm, and the testing points are arranged as follows: figure 1As shown, the test beam 1 is loaded symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com