Method for producing rare-earth magnet

一种制造方法、稀土的技术,应用在电感/变压器/磁铁制造、磁性物体、磁性材料等方向,能够解决矫顽力性能降低、晶界相率降低、没有公开解决等问题,达到矫顽力性能高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] (Method for manufacturing rare earth magnets)

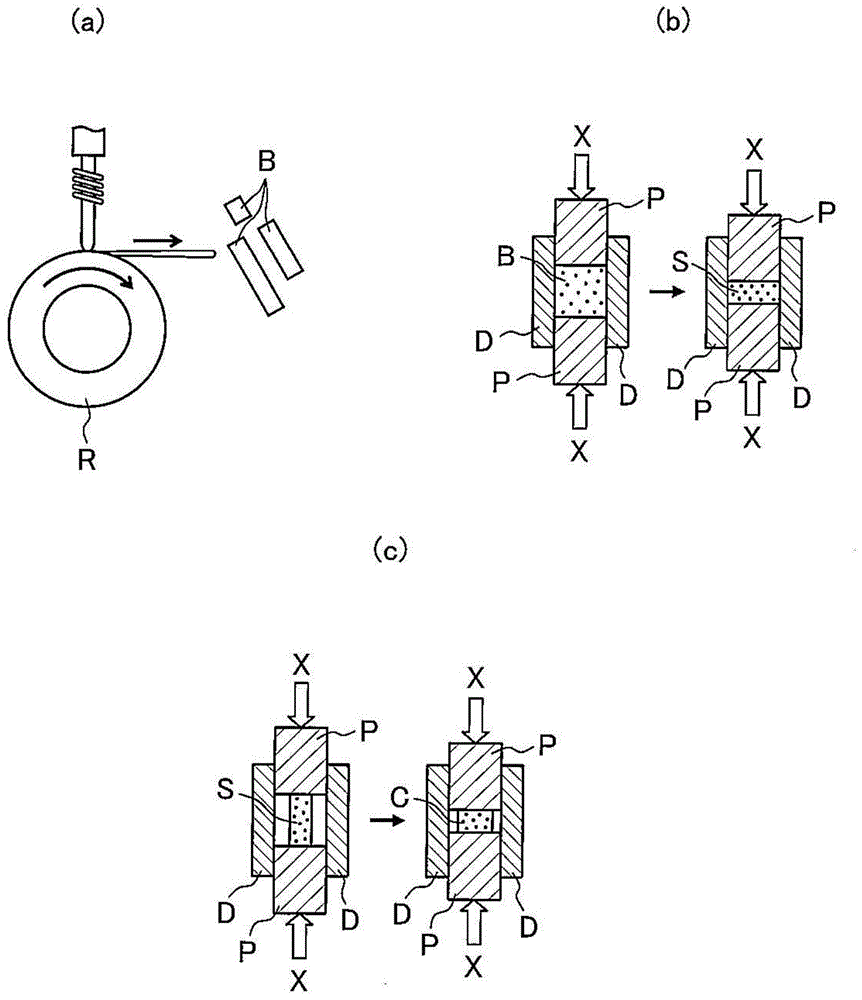

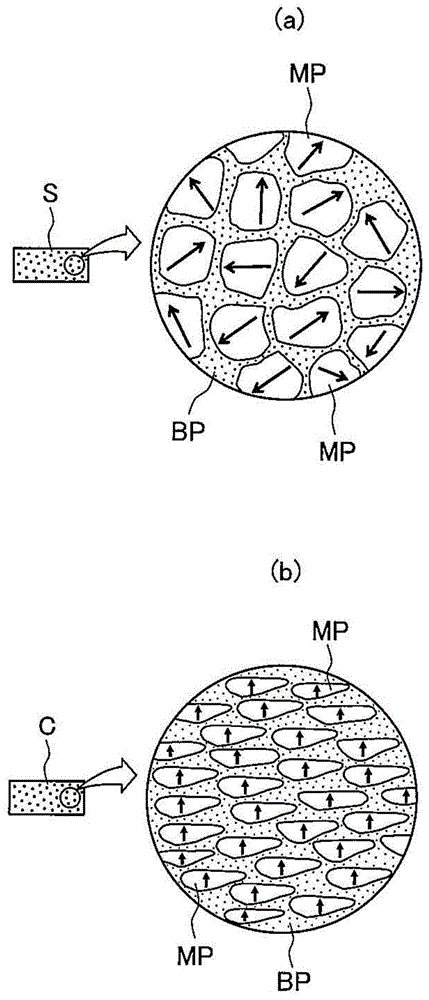

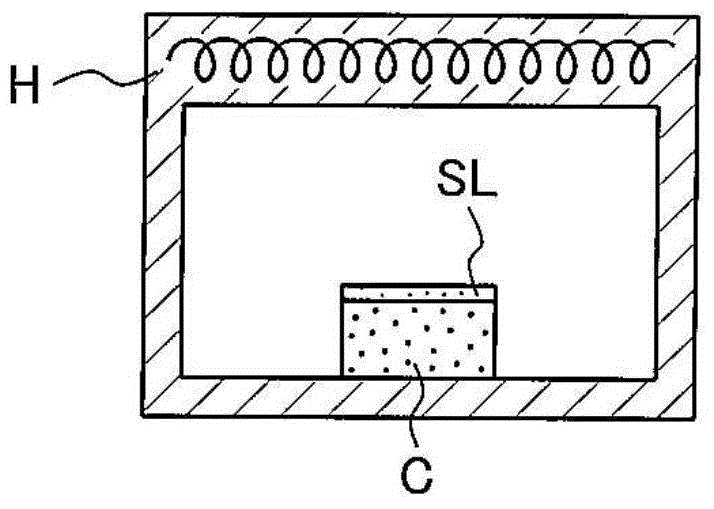

[0047] figure 1 (a), figure 1 (b) is a schematic diagram illustrating the first step of the manufacturing method of the rare earth magnet of the present invention in this order, figure 1 (c) is a schematic diagram explaining the second step. In addition, image 3 It is a schematic diagram explaining the third step of the method of manufacturing the rare earth magnet of the present invention. In addition, figure 2 (a) is stated in figure 1 (b) A picture of the microstructure of the sintered body shown in, figure 2 (b) is the description figure 1 (c) A diagram of the microstructure of the rare earth magnet precursor. In addition, Figure 4 It is a diagram showing the microstructure of the crystal structure of the manufactured rare earth magnet, Figure 5 Is to Figure 4 The main phase and the grain boundary phase in the image are further enlarged.

[0048] Such as figure 1 (a) As shown in (a), in a furnace not shown in an Ar g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com