Valve devices for internal combustion engines

A technology for valve devices and internal combustion engines, which is applied to valve devices, mechanical equipment, engine components, etc., can solve the problems of insufficient sealing and valve adjustability due to thermal characteristics, and reduce the number of components, improve service life, and simplify Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

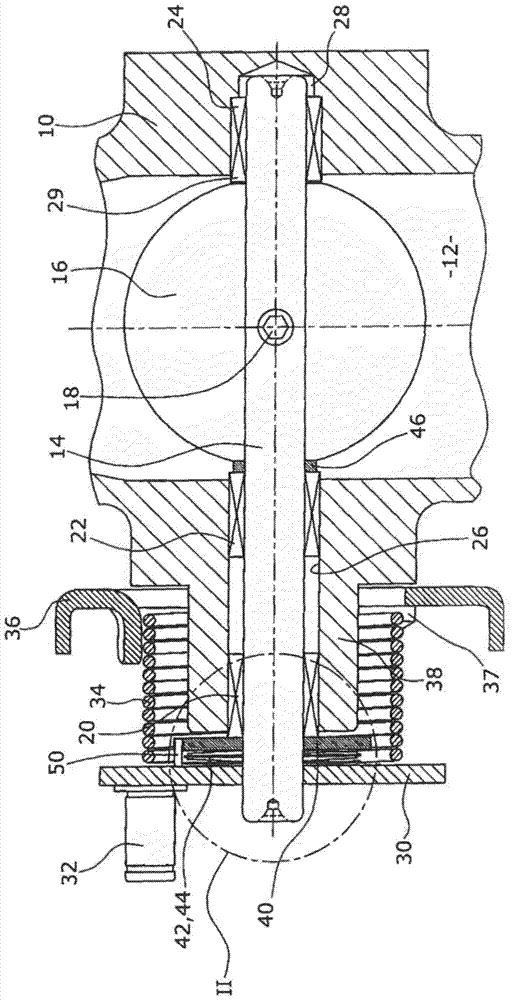

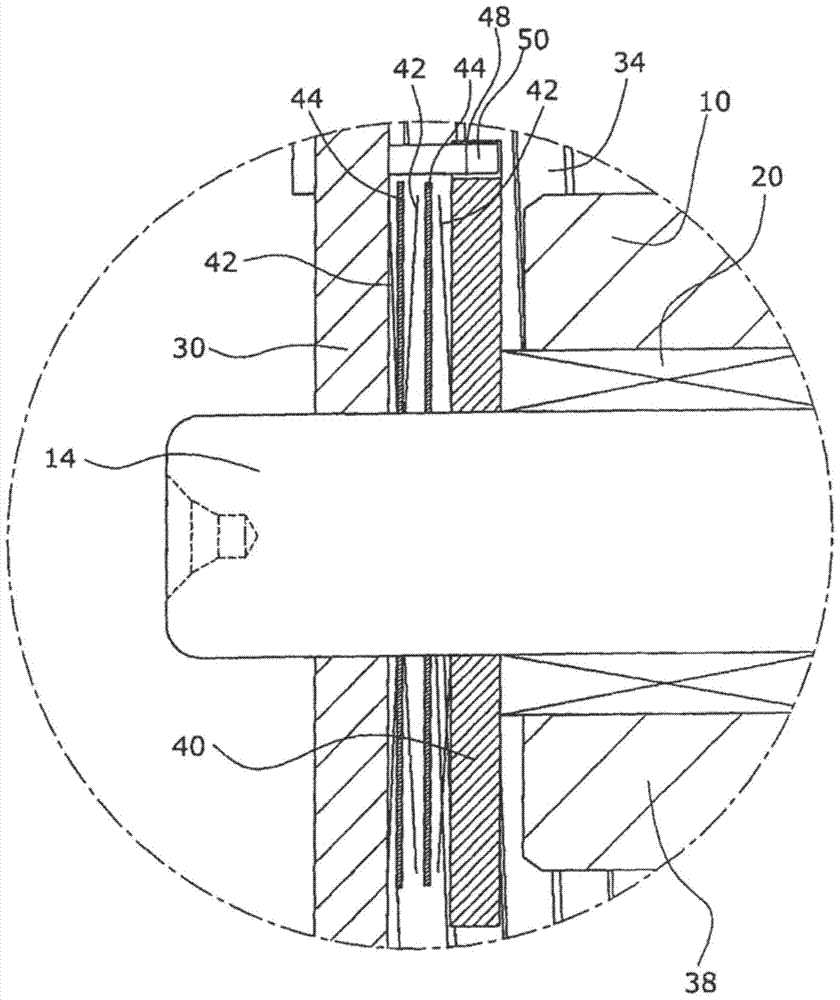

[0022] The flap arrangement according to the invention consists of a flow housing 10 in which a flow channel 12 is formed, for example through which exhaust gas can flow.

[0023] The flow channel 12 is divided in half by an adjusting shaft 14 in cross section, to which a valve body 16 is fastened by means of screws 18 . The adjusting shaft 14 is mounted in the flow housing 10 via three bushings 20 , 22 , 24 , of which the first two bushings 20 , 22 are seated in a through-opening 26 through which the adjusting shaft 14 passes from the The flow housing 10 protrudes outwards, and a third bushing 24 is seated on the side opposite the bore 26 in a blind hole 28 formed in the flow housing 10 , wherein the third bushing 24 has an axial direction The ends protrude into the flow channel 12 . Correspondingly, there are bearings on both sides of the adjusting shaft 14 on the side opposite to the central axis of the flow housing 10 .

[0024] On the outwardly protruding end of the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com