Preparation method for sodium borohydride hydrolysis hydrogen production catalyst and carrier thereof

A catalyst carrier, sodium borohydride technology, applied in catalyst carriers, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as corrosion, active component shedding, pulverization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

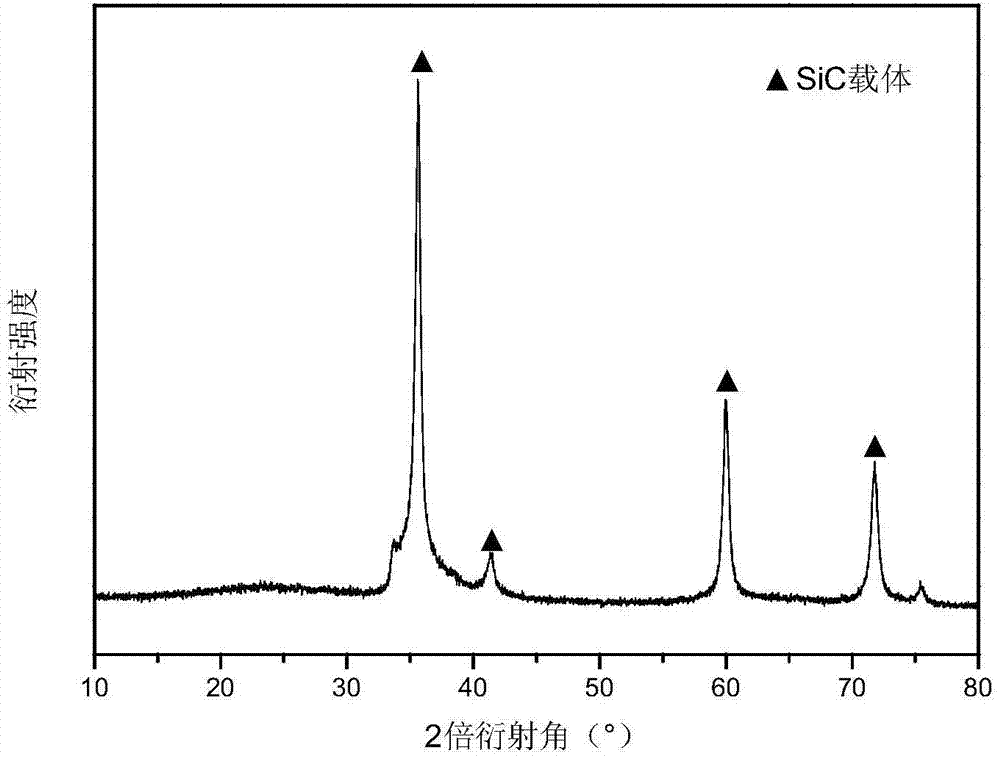

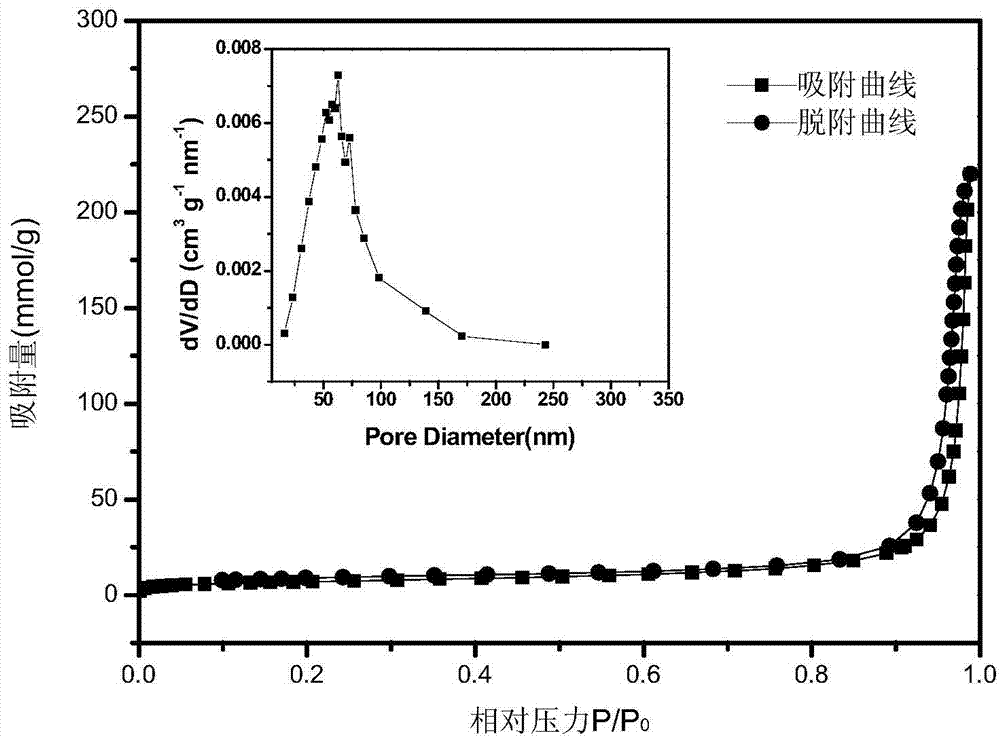

[0041] (1) Carrier preparation: 9 g of silicon carbide powder with a particle size of 40 nm and 6 g of silicon carbide powder with a particle size of 500 nm were uniformly mixed. 2g of polyethylene glycol binder and 2g of cyclodextrin pore-forming agent are dissolved in 10ml of ethanol, and mixed with silicon carbide powder. Extruded by extruder (diameter 2mm), dried naturally. Put the dried sample into a tube furnace, raise the temperature at 5 °C / min to 1450 °C for 3 h in an Ar atmosphere, and cool naturally. Put it into a muffle furnace at 700°C and keep it in air for 2h, then cool to room temperature. Catalyst supports such as figure 1 Shown, XRD as figure 2 As shown, the specific surface area and pore size distribution are as follows image 3 shown.

[0042] (2) Carrier surface treatment: the carrier was refluxed in concentrated nitric acid with a mass fraction of 65% at 70° C. for 24 hours, washed with distilled water three times, and dried for later use. Wherein ...

Embodiment 2

[0048] 9g of silicon carbide powder with a particle size of 40nm and 6g of silicon carbide powder with a particle size of 500nm are uniformly mixed. 2g of polyvinyl alcohol binder and 2g of cyclodextrin pore-forming agent were dissolved in 10ml of ethanol, and mixed with silicon carbide powder. Extruded by extruder (diameter 2mm), dried naturally. Put the dried sample into a tube furnace, raise the temperature at 5 °C / min to 1450 °C for 3 h in an Ar atmosphere, and cool naturally. Put it into a muffle furnace at 700°C and keep it in air for 2h, then cool to room temperature. A catalyst support is prepared.

[0049] The surface treatment of the carrier and the preparation process of the catalyst are the same as in Example 1.

Embodiment 3

[0051] 9g of silicon carbide powder with a particle size of 40nm and 6g of silicon carbide powder with a particle size of 500nm are uniformly mixed. Dissolve 2g cyclodextrin pore-forming agent and 2g polyethylene glycol binder in 10ml ethanol, mix with silicon carbide powder, and then add 3% Al 2 o 3 , as a sintering aid. Extruded by extruder (diameter 2mm), dried naturally. Put the dried sample into a tube furnace, raise the temperature at 5 °C / min to 1450 °C for 3 h in an Ar atmosphere, and cool naturally. The catalyst carrier is obtained by washing with deionized water to remove inorganic salts.

[0052] The surface treatment of the carrier and the preparation process of the catalyst are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap