A kind of pulse tapping microball bouncing device

A bouncing device and pulse technology, which are applied in the field of pulse tapping microball bouncing devices, can solve problems such as inability to meet, and achieve the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

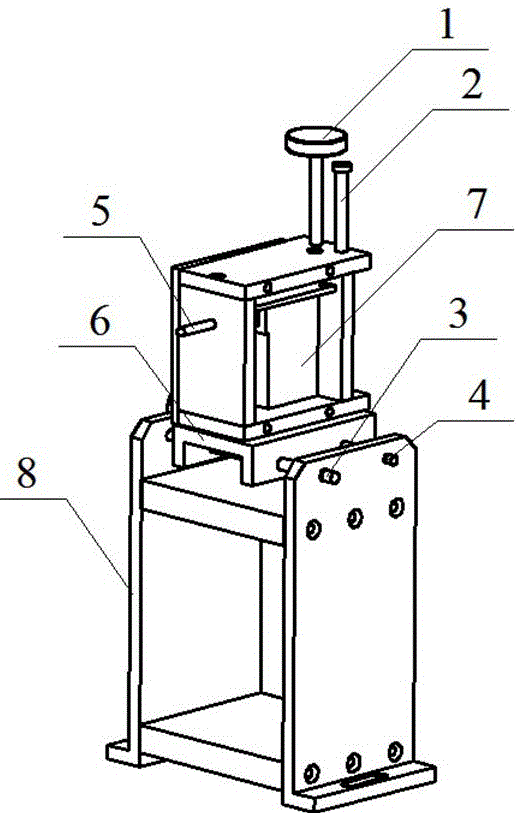

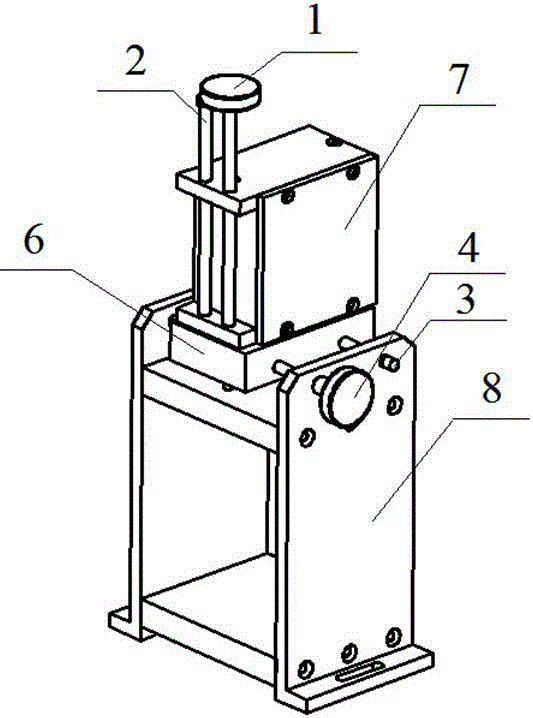

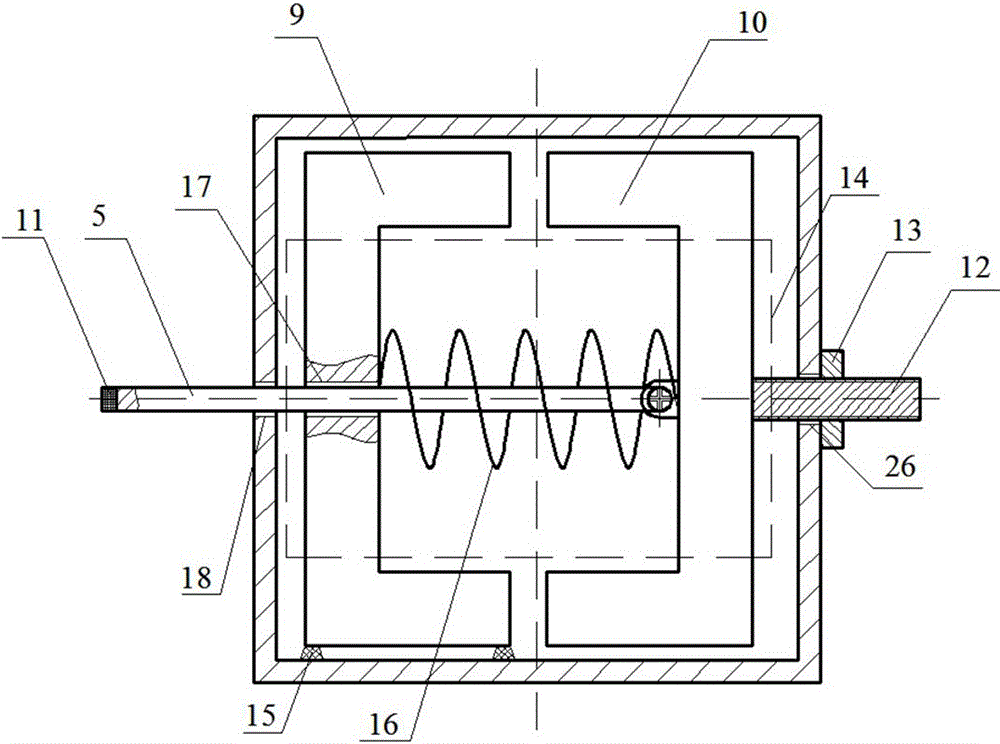

[0028] figure 1 It is a front view of the pulse percussion actuator in the pulse percussion microsphere bouncing device of the present invention, figure 2 It is a rear view of the pulse percussion actuator in the pulse percussion microsphere bouncing device of the present invention, image 3 It is a structural schematic diagram of the electromagnetic box in the present invention, Figure 4 It is a structural schematic diagram of the sieve disk assembly under attack in the present invention, Figure 5 for Figure 4 Middle A-A partial top view. exist Figure 1-Figure 5 Among them, the pulse percussion microsphere bouncing device of the present invention contains a pulse percussion generator and a sieve disk assembly; the pulse percussion generator includes a pulse percussion controller and a pulse percussion actuator, and the pulse percussion controller provides The voltage pulse signal with adjustable pulse period is sent to the pulse percussion actuator.

[0029] The pu...

Embodiment 2

[0041] The structure of this embodiment is the same as that of Embodiment 1, except that the mesh size of the sieve is 65% of the diameter of the microspheres, and the diameter of the filaments on the sieve is 25% of the diameter of the microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com