Method for producing large diameter thick wall gr15 bearing tube with steel ingot

A large-diameter, bearing tube technology, applied in the field of Gr15 bearing tubes, can solve the problems of large forging blanks, high production costs, and high difficulty in the production process of bearing tubes, achieve high processing forming rate, improve service life, reduce production difficulty and production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

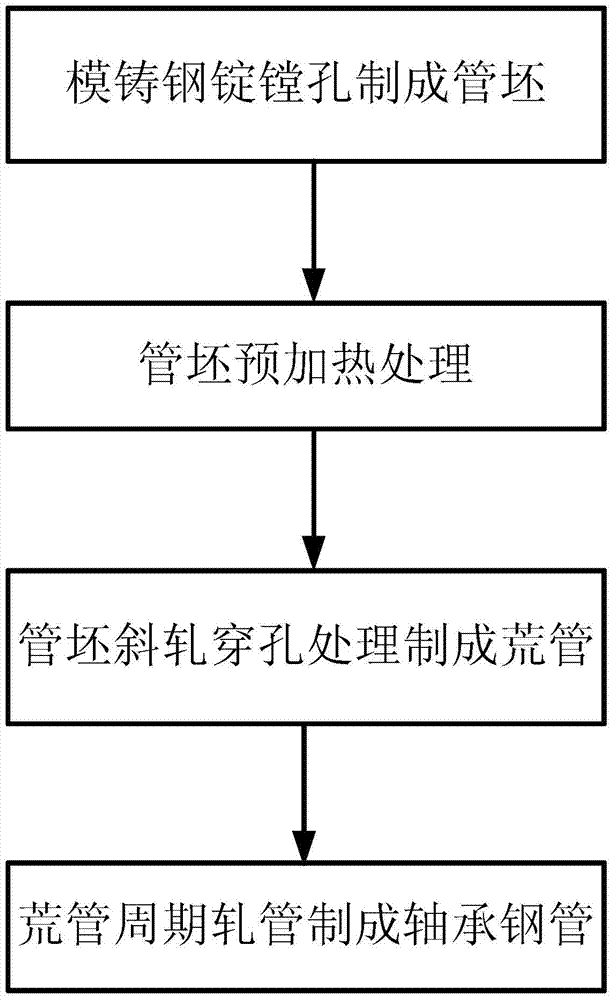

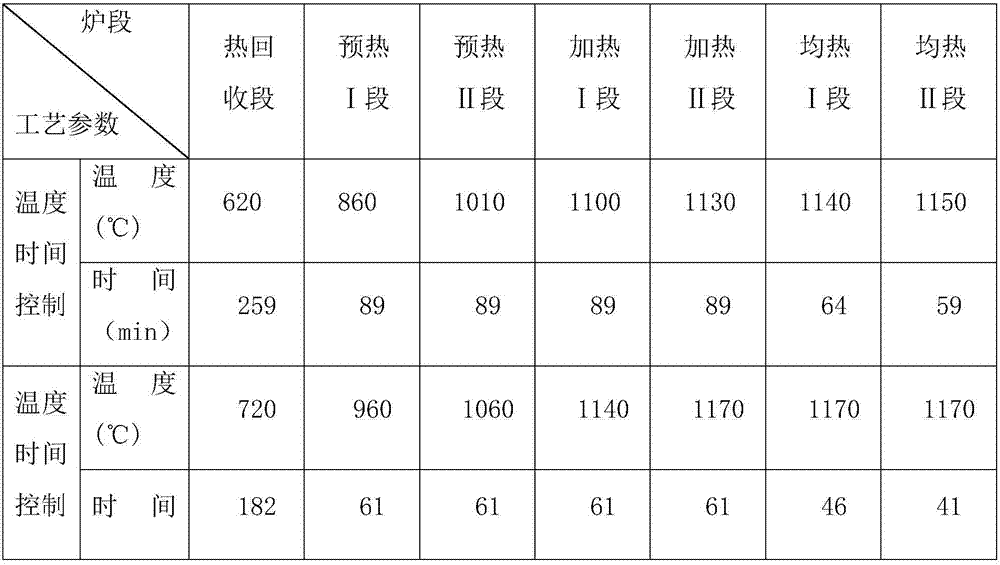

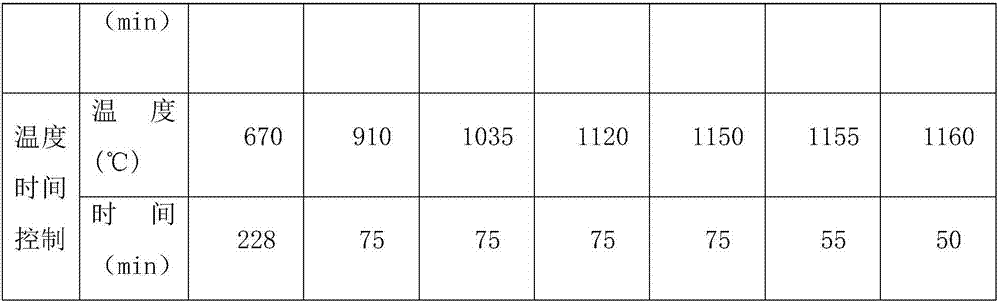

[0025] Such as figure 1 As shown, the method for producing a Gr15 bearing tube with an outer diameter of 300mm or more and a wall thickness greater than 40mm with a steel ingot of the present invention adopts chemical compositions of C: 0.95-1.05wt%, Mn: 0.25-0.45wt%, Si: 0.15- 0.35wt%, Cr: 1.40~1.65wt%, S: ≤0.020wt%, P: ≤0.027wt%, the balance is Fe and unavoidable impurities, the outer diameter of 300mm or more die-cast steel ingots, for die-casting The steel ingot is made into a tube blank according to the die-casting steel ingot boring, the tube blank is preheated, the tube blank is obliquely rolled and pierced to make a barren tube, and the barren tube is rolled periodically to make a bearing tube. The processing steps are processed into a large-diameter thick-walled Gr15 bearing tube . The specific process is as follows:

[0026] Step 1. Boring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com