Commutator automatic production equipment

A kind of production equipment, fully automatic technology, applied in the direction of metal processing equipment, measuring/indicating equipment, other manufacturing equipment/tools, etc., can solve the problems of product quality stability, high work intensity, backward automation equipment, etc., and achieve product consistency High degree of reliability, improved production efficiency, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

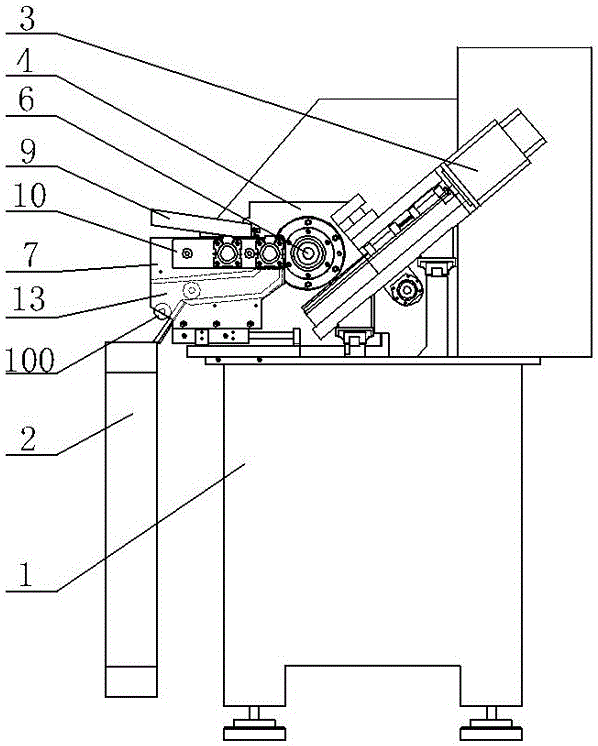

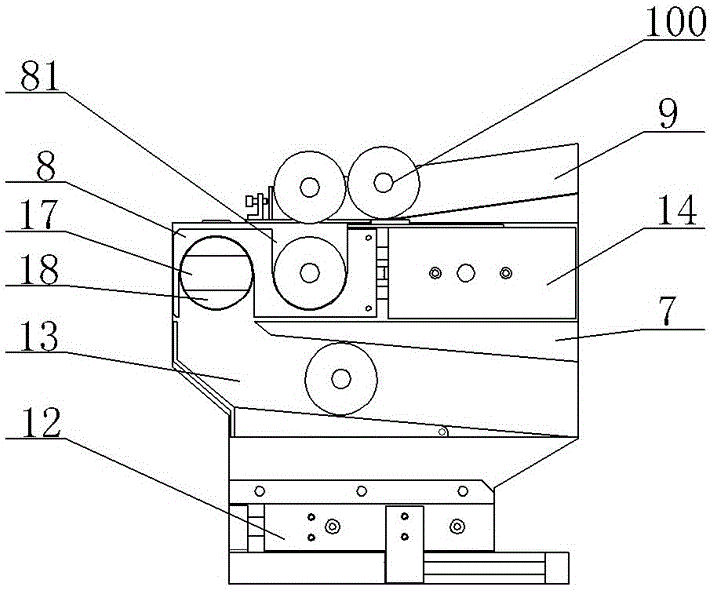

[0028] Such as figure 1 As shown, the commutator automatic production equipment provided by the present invention includes a hopper and a feeding belt, and one side of the feeding belt is sequentially provided with an inner circle processing mechanism, an outer circle processing mechanism, a groove milling mechanism, a milling hook mechanism, a hook mechanism and a detection Mechanism, the hopper is set on the other side of the feeding belt and the hopper is connected to the inner circle processing mechanism, there is a sand grinding mechanism between the milling hook mechanism and the hook mechanism, and a grinding mechanism between the hook mechanism and the detection mechanism, the machine of the feeding belt The racks are respectively equipped with trays and push rods corresponding to the feeding channels of each mechanism. The trays can move up and down on the rack, and the push rods correspond to the trays raised to the top.

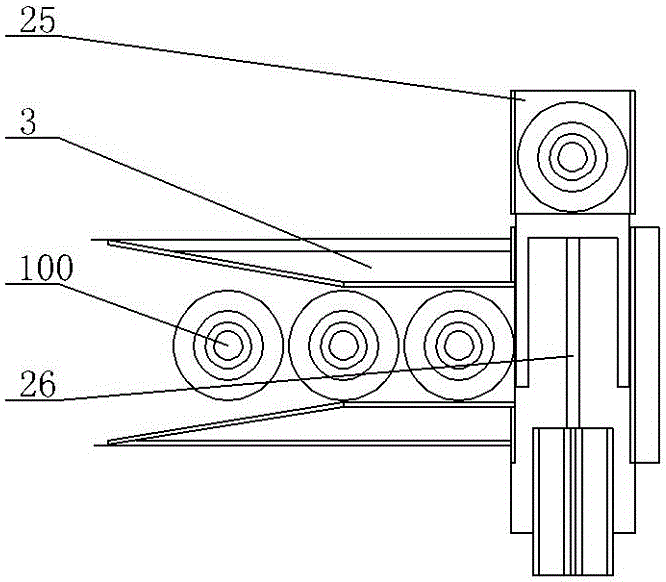

[0029] Such as Figure 2~Figure 6 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com