No-power water-smearing no-bottom paper label printer

A linerless paper and printer technology, applied in typewriters, printing devices, printing and other directions, can solve the problems of increased manufacturing cost, unstable water-coating performance of water-coating blocks, complicated structure, etc., and achieves the effect of simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

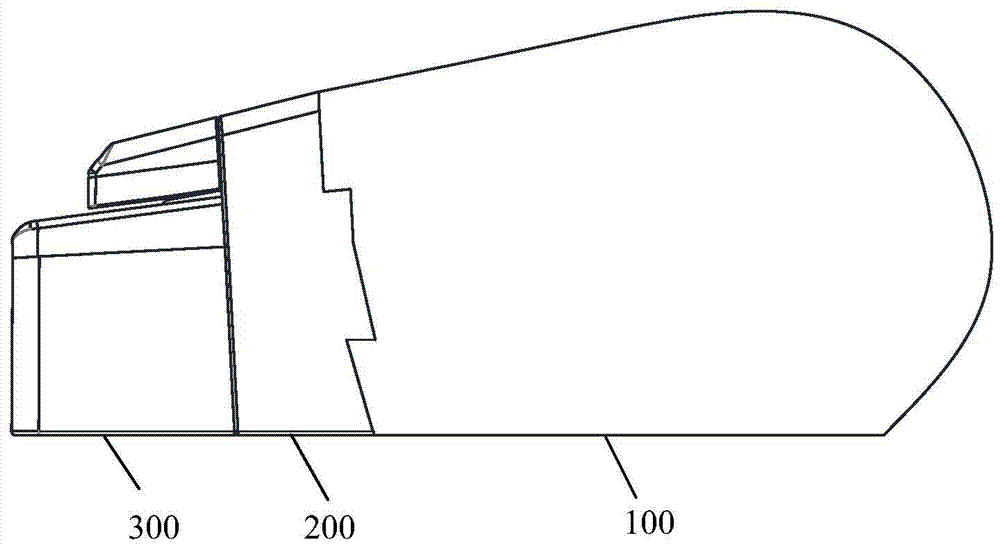

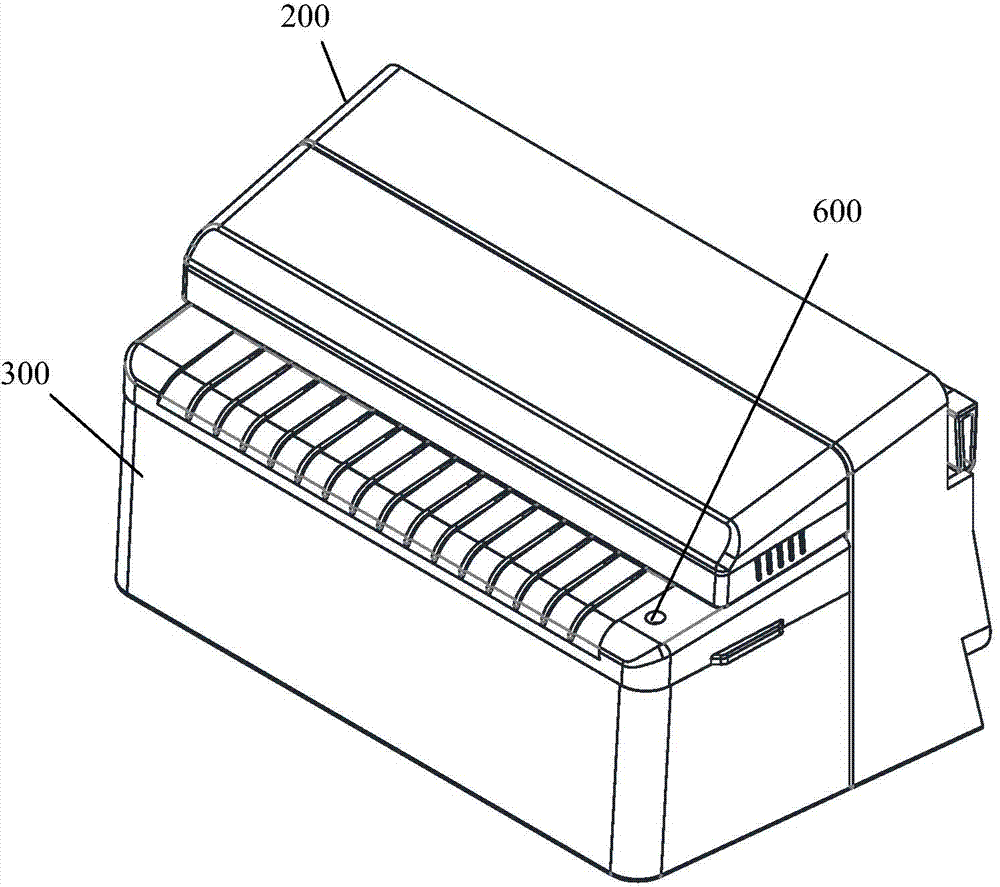

[0030] Such as figure 1 As shown, the non-powered water-filling bottomless paper label printer of the present invention includes a printing module 100 , a paper cutting module 200 and a watering module 300 .

[0031] Wherein, the paper cutting module 200 is installed in front of the printing module 100, and the water coating module 300 is installed in front of the paper cutting module 200, and the three are combined together.

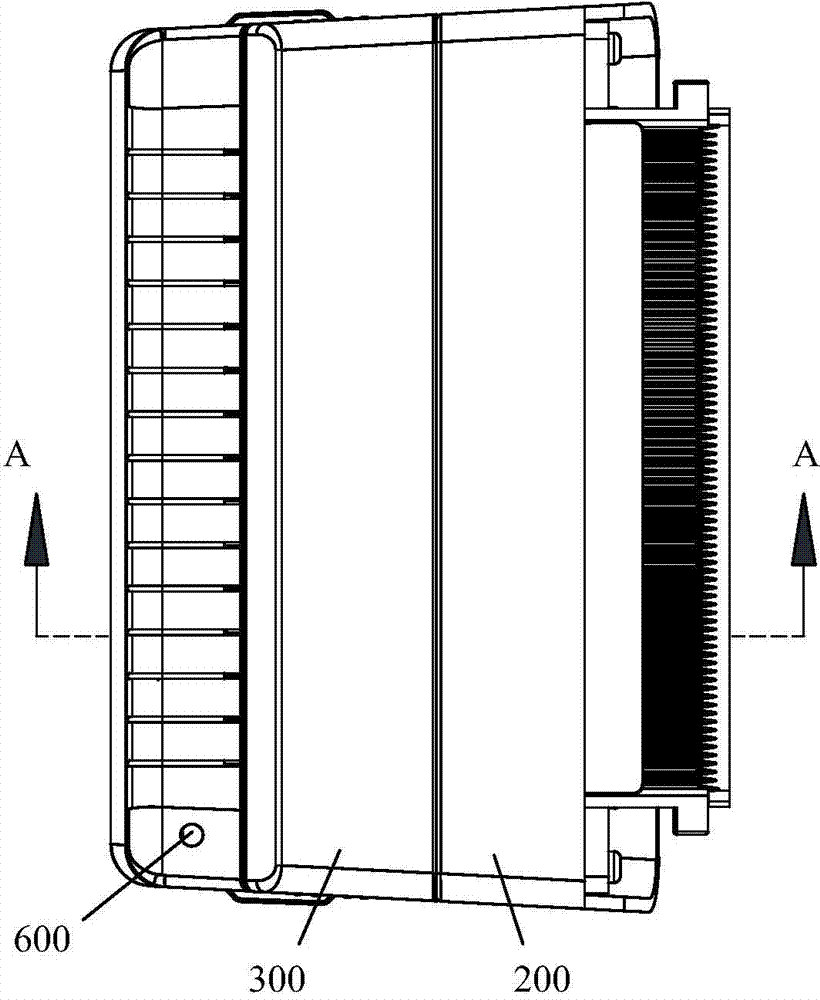

[0032] Such as Figure 2-Figure 4 As shown, the water coating module 300 includes a housing 301, a paper pressing part 302, and a water coating part made of a PVA absorbent sponge 303. The PVA absorbent sponge 303 is made into a sheet with a thickness of 1.5-2.5 mm. 2mm, the shape is a long rectangle.

[0033] The casing 301 is composed of a water tank 310 , a lower cover 320 and an upper cover 330 .

[0034] Figure 4 combine Figure 5 As shown, the upper part of the water tank 310 has an opening 311 . The lower cover plate 320 covers the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com