Rotary spray device

A technology of rotating spray and sleeve shaft, applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of low production efficiency, overflowing drainage, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is described in detail below. The embodiment of the present invention is only for illustrating a specific structure, and the scale of the structure is not limited by the embodiment.

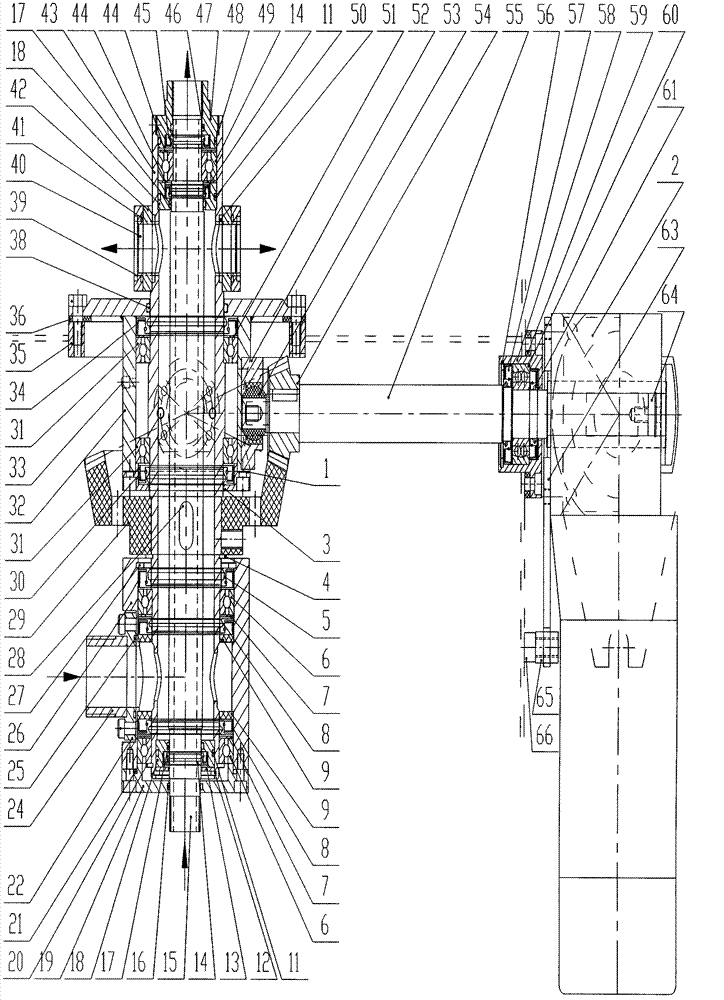

[0027] see figure 1 , the rotary spraying device of the present invention includes a hollow shaft 15 as an inner ring located at the center of the rotary spraying device, the lower end of which is connected to the water inlet pipeline; the sleeve shaft 43 is located outside the hollow shaft 15 to form a middle ring; The lower part of the sleeve shaft 43 is provided with two round holes, and the upper part of the sleeve shaft 43 is also provided with two round holes; the bearing seat 32 is provided with two bearings 31 to support the sleeve shaft 43; the insert ring 52 with the joint bearing 53 is used The screw is fixed on the bearing seat 32; the inner end of the transmission shaft 55 is in a stepped structure, the main gear 54 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com