Motor car gear box grounding device

A grounding device and gear box technology, applied in locomotives, connections, connection contact materials, etc., can solve problems such as improper installation, disassembly to observe, and high current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

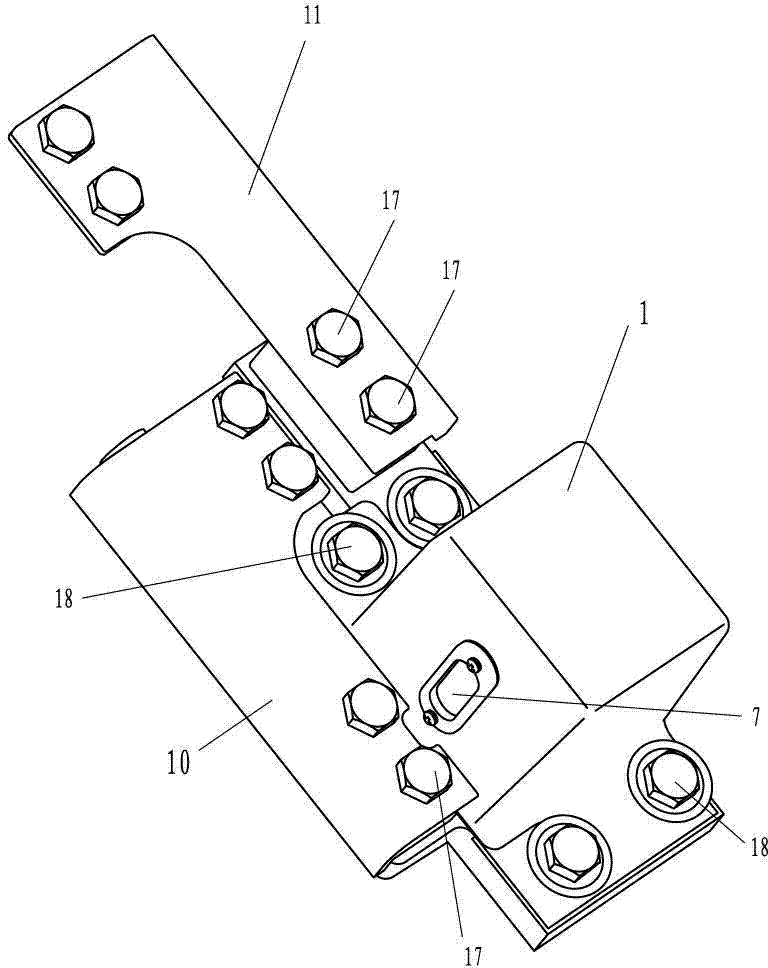

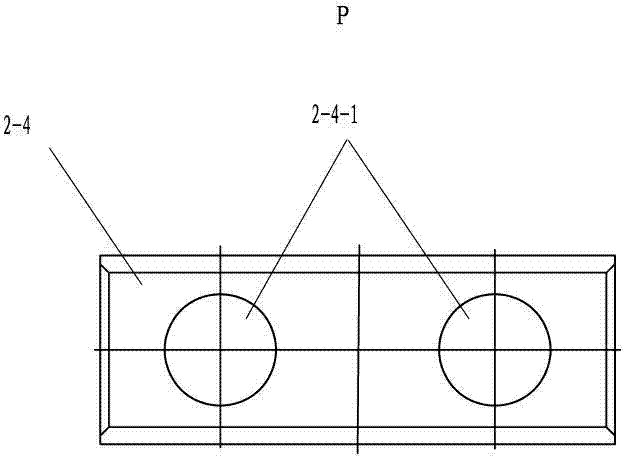

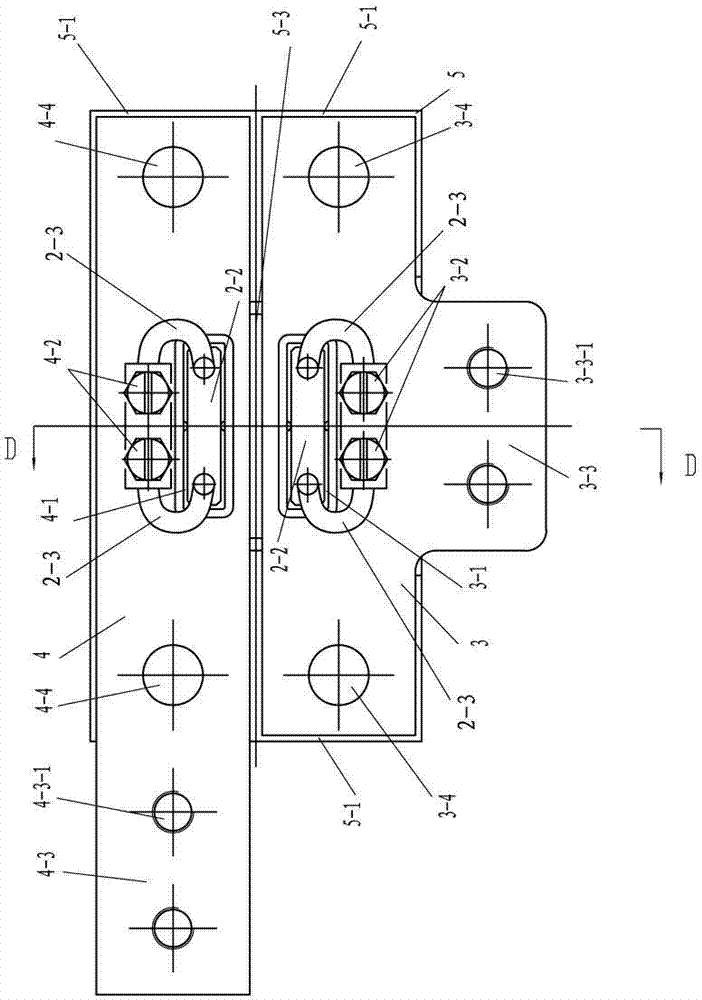

[0042] Such as Figure 1~25As shown, the grounding device of the motor vehicle gearbox of the present invention includes a grounding box 1, a carbon brush 2, an insulator 5, 8, 9 and a wiring device structure 10, 11, 12, 13, 14, and also includes a first carbon brush support Frame 3, second carbon brush support frame 4, two scroll spring assemblies 6, two observation window assemblies 7, the first carbon brush support frame 3 and the second carbon brush support frame 4 pass bolts 18 and insulators 5 , 8, 9 are fixed on the bottom of the grounding box 1 and the first carbon brush support frame 3, the second carbon brush support frame 4 and the grounding box 1 together form the installation cavity 1-3, the first carbon brush support frame 3 and the second carbon brush support frame 4 respectively have a first carbon brush guide hole 3-1 and a second carbon brush guide hole 4-1, and there are two carbon brushes 2 which are inserted into the first carbon brush with sliding fit res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com