Novel automotive front and rear wall

A technology for front and rear panels and automobiles, applied to vehicle parts, upper structure sub-assemblies, layered products, etc., can solve the problems of large impact force, easy deformation or even broken, and achieve light weight, not easy to deform and break, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

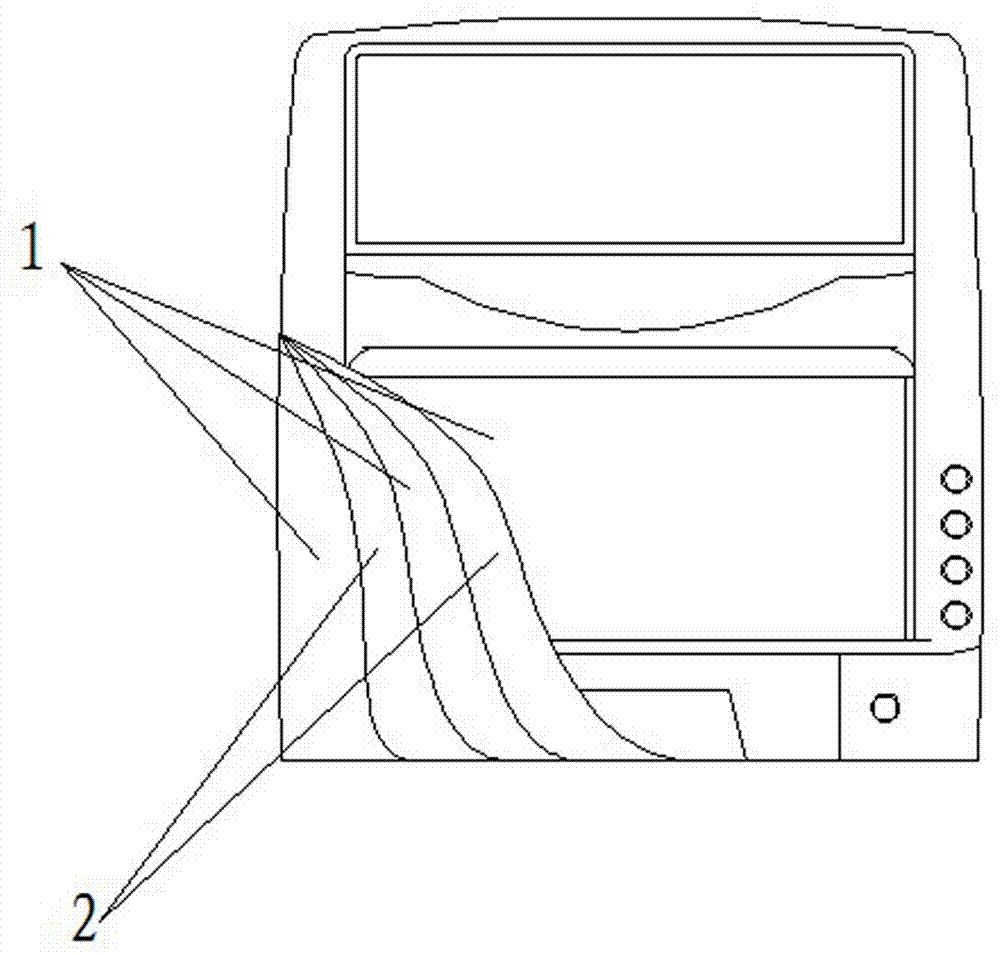

[0007] see figure 1 , a new type of automobile front and rear wall, it includes a reinforcement layer 1, a resin layer 2, from the outermost layer to the innermost layer are reinforcement layer 1, resin layer 2, reinforcement layer 1, resin layer 2, reinforcement layer 1, a total of five Floor.

[0008] The strength of the reinforced layer is very high, but the layers are loose, and can only bear tensile force, but not bending, shearing and compressive stress, and it is not easy to make a fixed geometric shape. It is a soft body. Compared with the reinforced layer, the resin layer , the strength and modulus are much lower, but can withstand large strains, often have viscoelasticity and elastoplasticity, and are ductile materials. The front and rear walls of the car made by combining them according to the present invention are hard and can withstand tension. Stress, but also withstand bending, compression and shear stress.

[0009] The novel automobile front and rear panels o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com