A kind of aviation tire provided with bead reinforcing glue

A technology of aviation tires and reinforcing rubber, which is applied to special tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of high deformation frequency, large heat generation in the upper part of the bead, and large load, so as to improve heat resistance Performance, good thermal conductivity, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

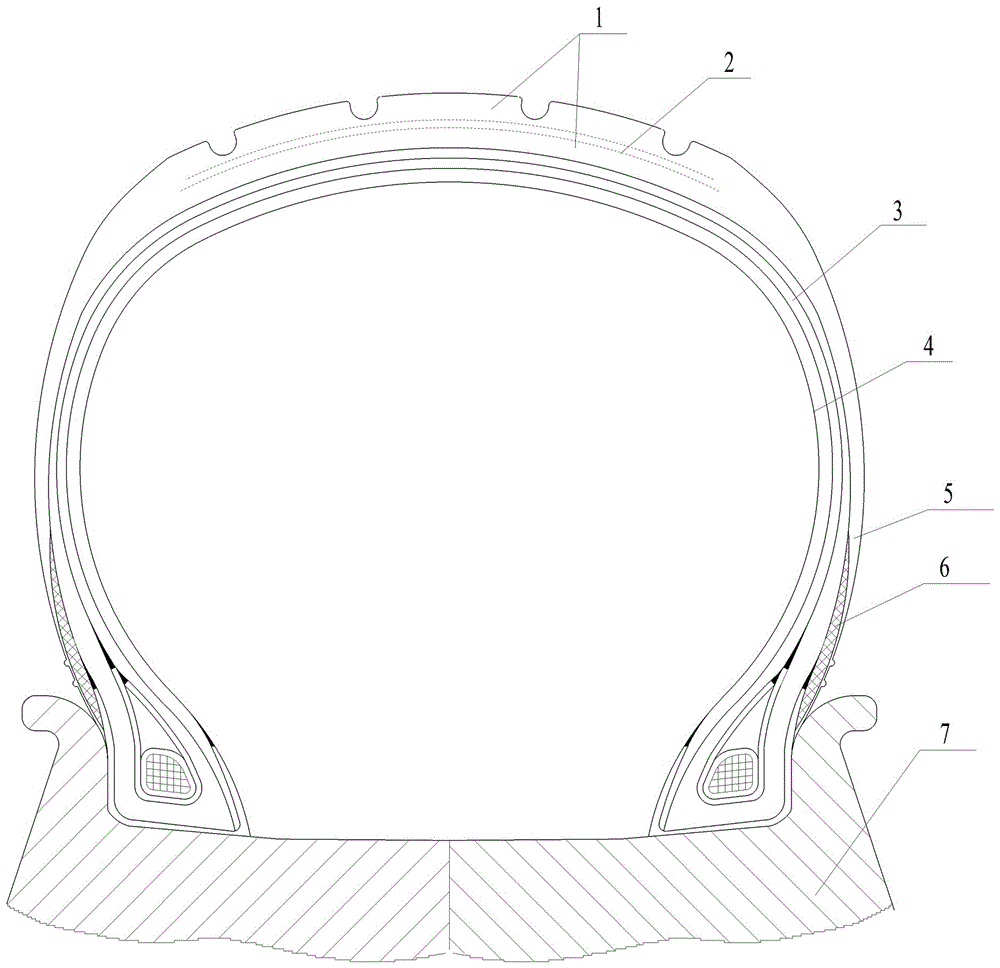

[0018] refer to figure 1 , an aviation tire provided with a bead reinforcing rubber, comprising a tread rubber 1, a reinforcing layer 2, a carcass ply 3, an airtight layer 4 and a sidewall rubber 5, and also includes a bead reinforcing rubber layer 6 , the bead reinforcing rubber layer 6 is arranged between the carcass ply 3 and the sidewall rubber 5 on the upper part of the tire bead, and is in an arc shape.

[0019] Specifically, the bead reinforcing rubber layer 6 is arranged on the upper part of the rim of the rim 7 and the lower part of the center horizontal line of the tire, sandwiched between the carcass ply 3 and the sidewall rubber 5, the bead reinforcing rubber layer 6 and the The carcass ply 3 and the sidewall rubber 5 are overlapped.

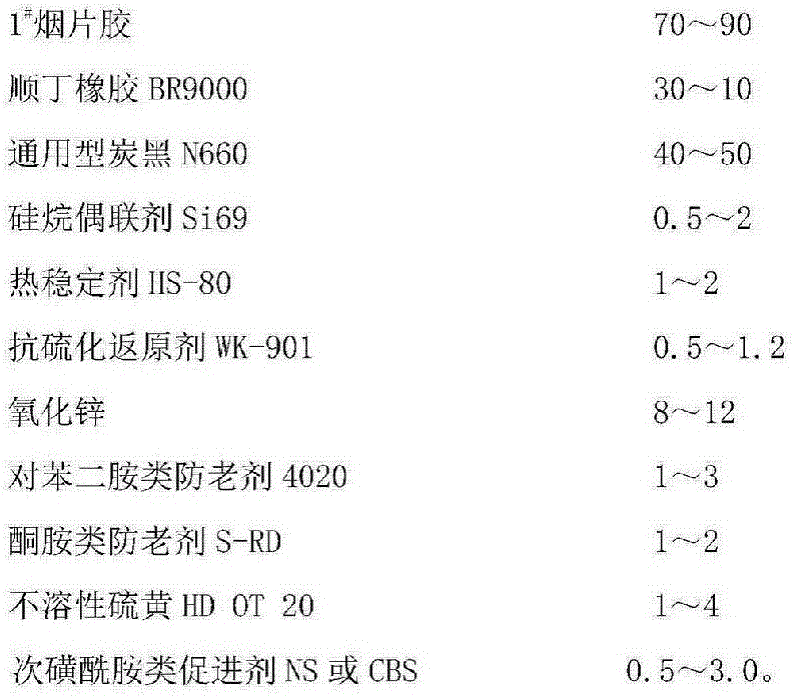

[0020] The bead-reinforcing glue for making the bead-reinforcing glue layer 6 above is composed of the following raw materials in parts by weight:

[0021]

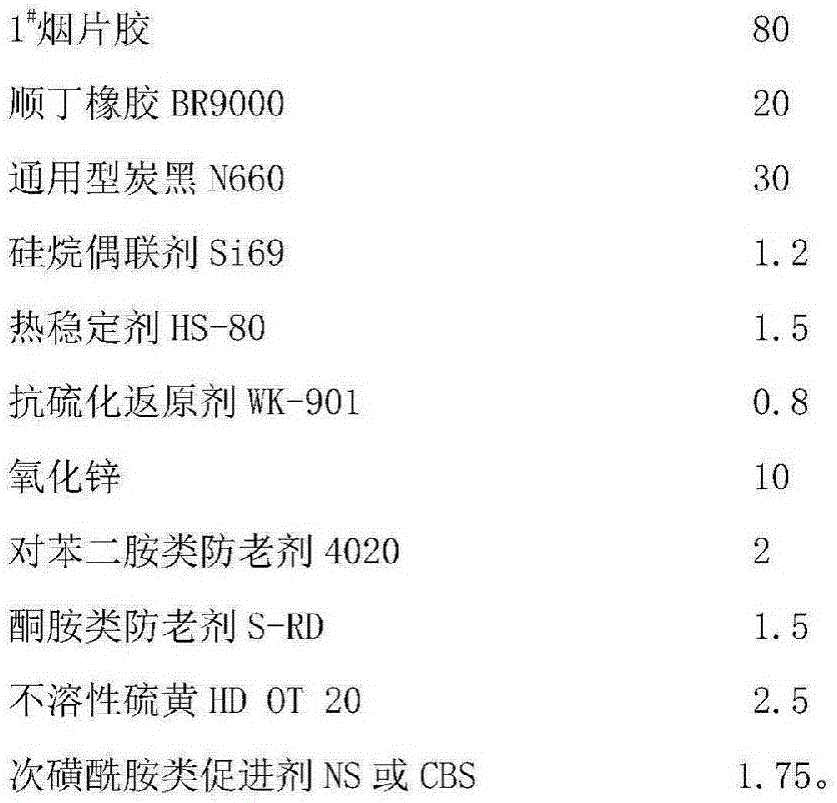

[0022] The formula of the present embodiment is that the weight propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com