Self-suction emptying device of powder tank for thermal spraying

A powder tank, self-priming technology, applied in coating, melting spray plating, metal material coating process and other directions, can solve the problems of easy quality problems, difficult to clean, easy to feed and difficult to discharge, etc. Good for health, difficult to clean, no environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means and creative features realized by the present invention easy to understand, the present invention will be further elaborated below.

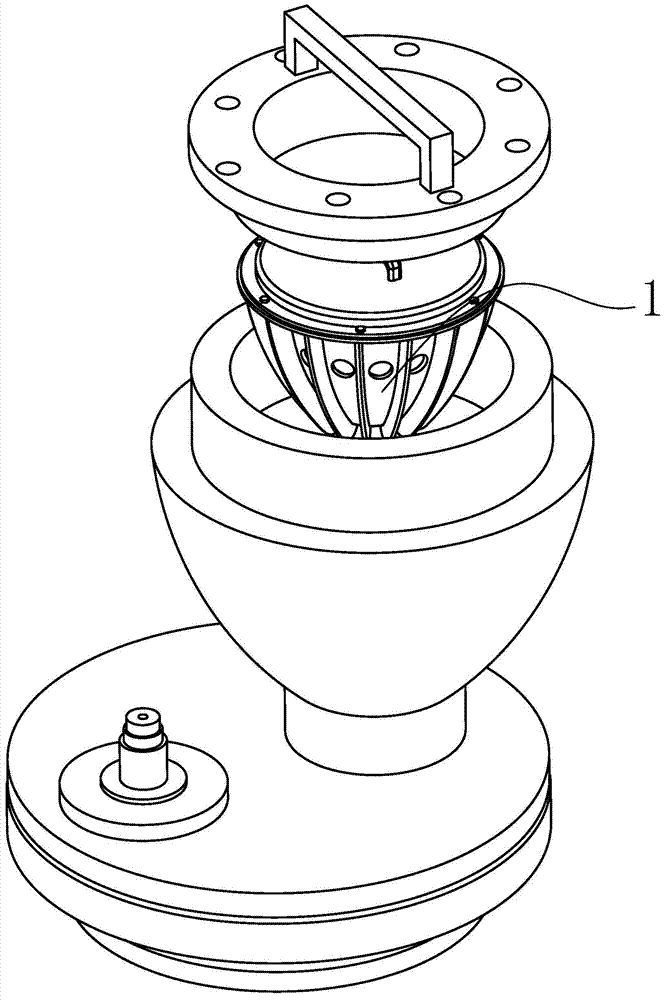

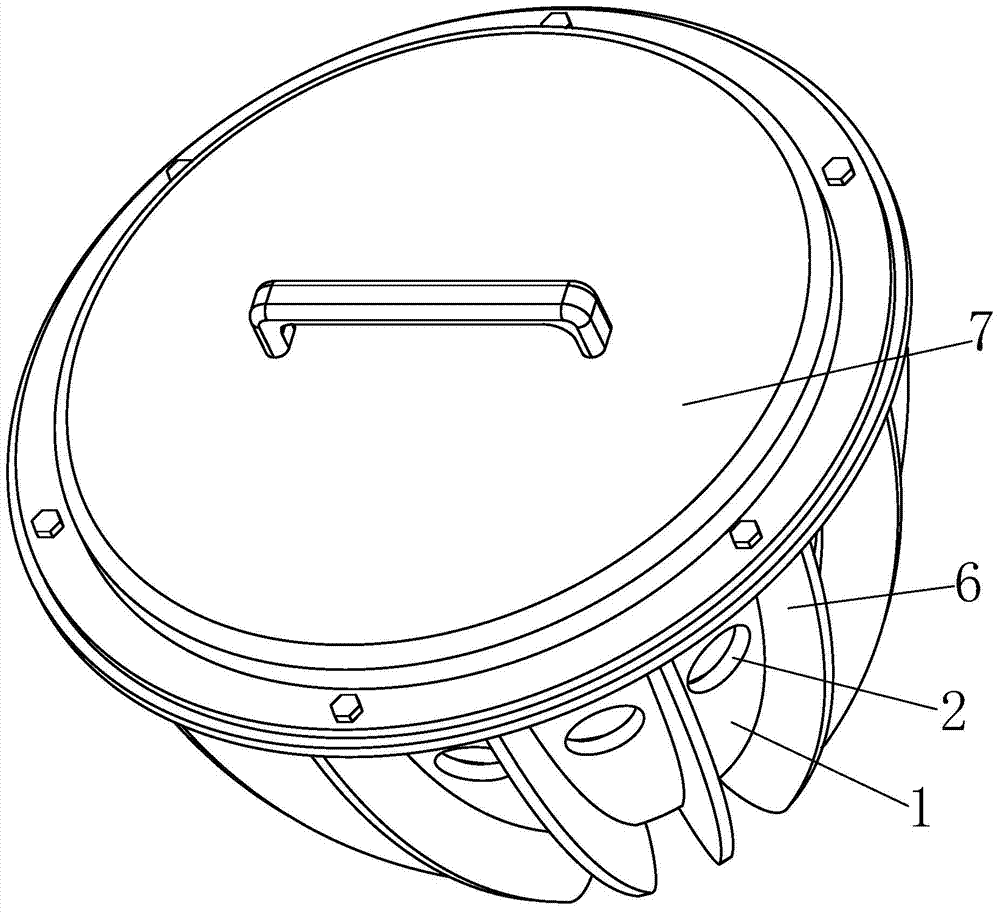

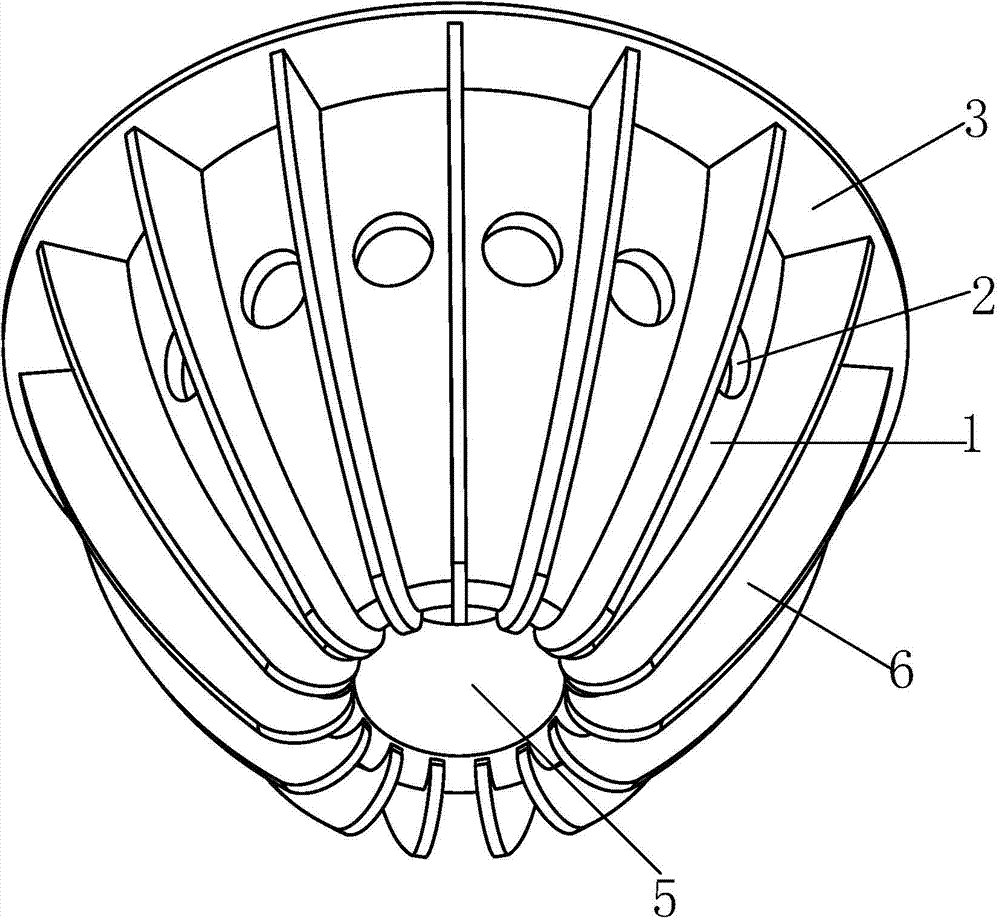

[0029] Such as Figure 1 to Figure 11 As shown, a self-priming emptying device for a powder tank for thermal spraying includes a tank body 1, the outer diameter of the tank body 1 decreases successively from top to bottom, and the outer side wall of the tank body 1 and the powder tank body The internal space is suitable so that when the tank body 1 is put into the powder tank, the gap between the tank body 1 and the powder tank is uniform and the gap is small, which is conducive to the full absorption of the powder in the tank body 1. The outer wall of the body 1 is evenly distributed with through holes 2, the upper edge of the tank body 1 is provided with a turning part 3 that is turned outwards in a circle, the upper end of the tank body 1 is provided with a circle of outer snap rings 4, and the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com