A self-anchored suspension bridge suspender tensioning process based on a self-balancing system

A self-anchored suspension bridge and self-balancing technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of long delays in changing positions of jacks, extension rods that cannot be used repeatedly, and the accuracy of total stations cannot be guaranteed and other problems, to achieve the effect of fewer jack position changes, faster measurement speed and less quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

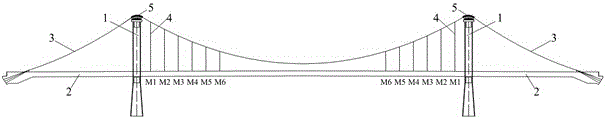

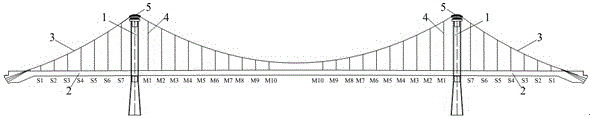

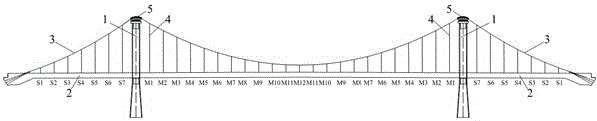

[0028] Such as Figure 1-3 As shown, taking the Qiancang Bridge in Qingtian County, Zhejiang Province as an example to introduce the boom tensioning process in detail, the Qiancang Bridge is a two-tower three-span prestressed concrete self-anchored suspension bridge with a span of 45m+120m+45m. The face width is 30m. This example self-anchored concrete suspension bridge boom tensioning construction technology needs 8 jacks to stretch the boom simultaneously, and it is characterized in that following steps:

[0029] (1) After the pouring of the main tower 1 and the main beam 2 is completed, the main cable 3 is erected, and the side-span suspenders S1-S7 and mid-span suspenders M1-M9 are installed, and all suspenders are not stretched.

[0030] (2) Stretch the mid-span suspenders M1-M6 from the bridge tower to the mid-span to the stress-free length. The first stage is completed.

[0031] (3) Stretch the side span suspender S4 once to the stress-free length.

[0032] (4) Stret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com