Supporting frame used for fixing holding pole

A technology of support frame and fixed frame, which is applied in the field of support frame for fixing poles, which can solve the problems of high endurance requirements of the ground base, difficulty in laying pull wires, and non-reusability, etc., to achieve light weight, improved ground endurance, and convenience The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

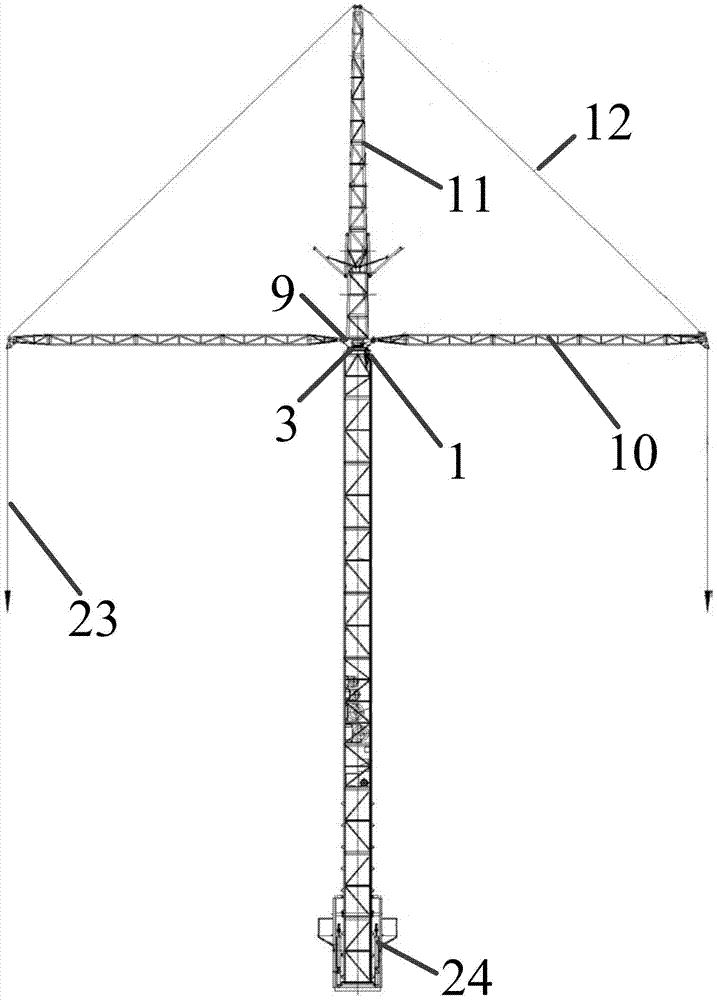

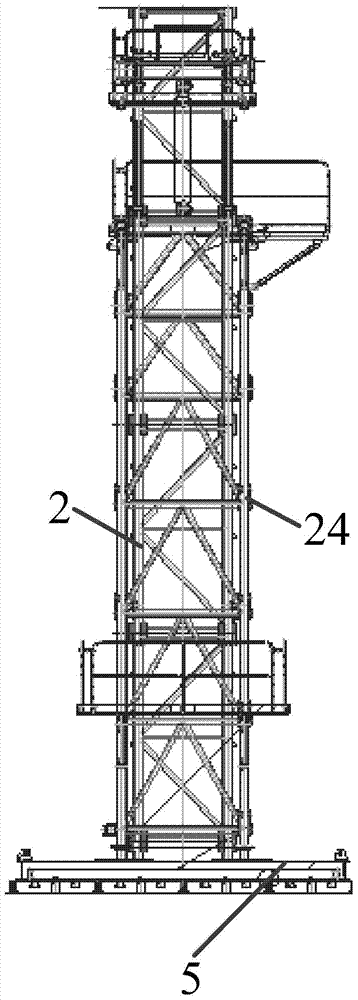

[0043] Such as figure 1 As shown, a support frame for fixing a pole, the pole is a pole body composed of a standard section 2, the support seat includes a base 4,

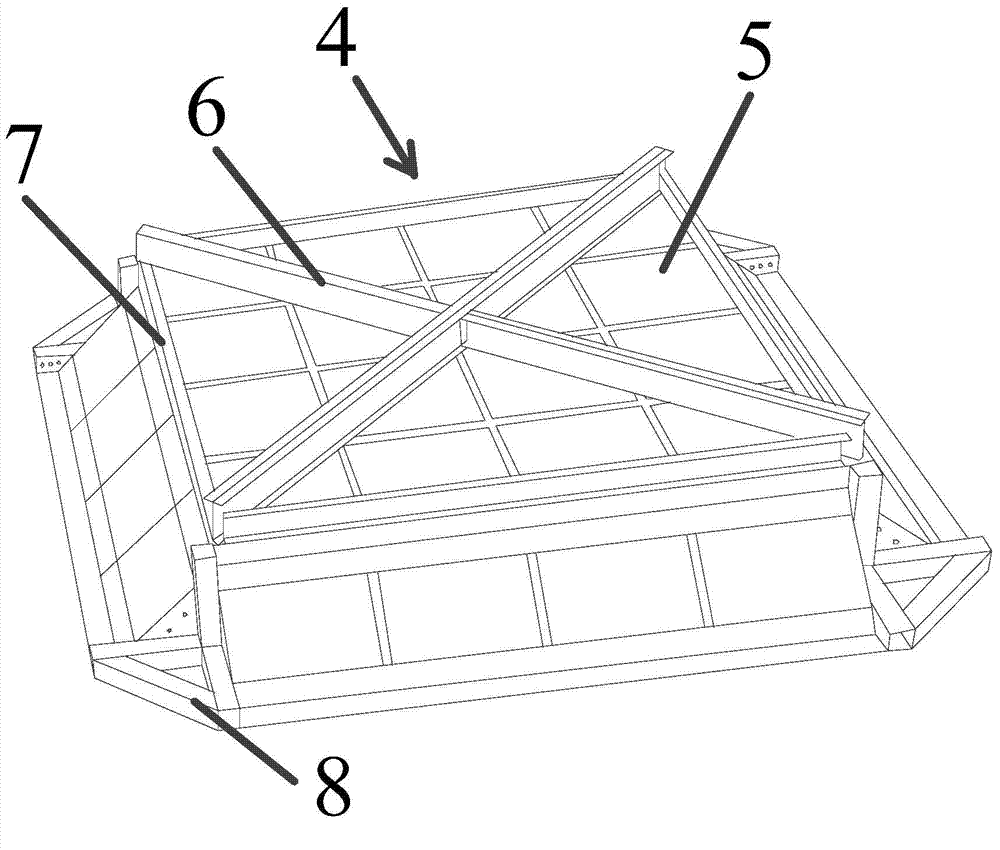

[0044] Such as image 3 As shown, the base 4 is a trapezoidal fixed seat in longitudinal section composed of a foundation 5 , a top frame 6 , a fixed frame 7 and an angle frame 8 .

[0045] Such as figure 1 with figure 2 As shown, the upper and lower ends of the pole main body are respectively provided with a support 1 and a sleeve frame 24;

[0046] The support 1 is provided with a slewing support 3, the slewing support 3 is provided with a rocker arm seat 9, the two sides of the rocker arm seat are provided with rocker arms 10, and the middle part of the rocker arm seat is longitudinally provided with a mast 11. The top of the mast 11 is provided with a luffing steel wire rope 12 respectively wound on the movable end of the rocker arm 10, and a lifting wire rope 23 is also wound on the movable end of the roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com