Gallery purifier for safety production of coal mine

A coal mine safety and purifier technology, applied in the field of purifiers, can solve problems such as poor results, and achieve the effects of saving water sources, reducing wind speed, and reducing the possibility of explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

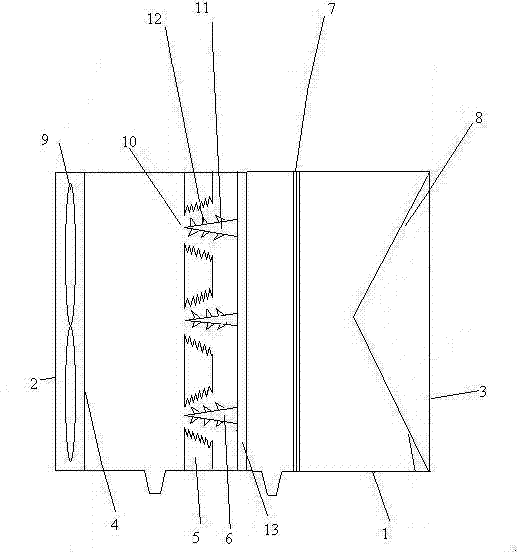

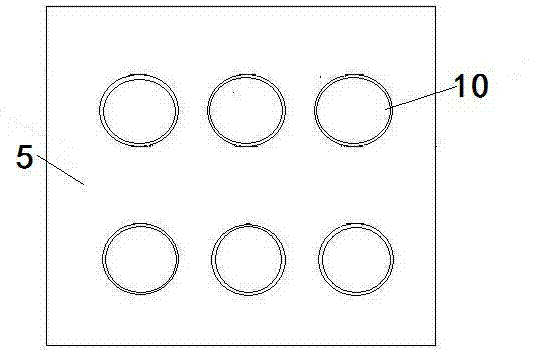

[0023] Such as figure 1 with figure 2 As shown, a tunnel purifier for coal mine safety production includes a purifier housing 1, an air inlet 2, an air outlet 3, an air inlet filter layer 4, a porous plate 5, a composite tapered water nozzle 6, and an air outlet Filter core 8 and fan 9, described air inlet is provided with fan 9, and the inner side of described fan 9 is provided with air inlet filter screen layer 4, and described perforated plate 5 is arranged on the other side of air inlet filter screen layer, described The perforated plate 5 is provided with a plurality of through holes 10, the thickness of which is 80mm-100mm, and the composite conical water nozzle 6 is inserted into the hole provided by the perforated plate, and the composite conical water nozzle 6 includes a The main cone-shaped water nozzle 11 that can spray water at the tip and the secondary cone-shaped water nozzle 12 that can be sprayed at the tip of a plurality of cone-shaped water nozzles inclined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap