Impeller top surrounding band and turbine

A technology of turbines and top enclosures, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as complex sealing forms, reduce gas bearing effects, reduce spiral flow effects, and reduce excitation force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

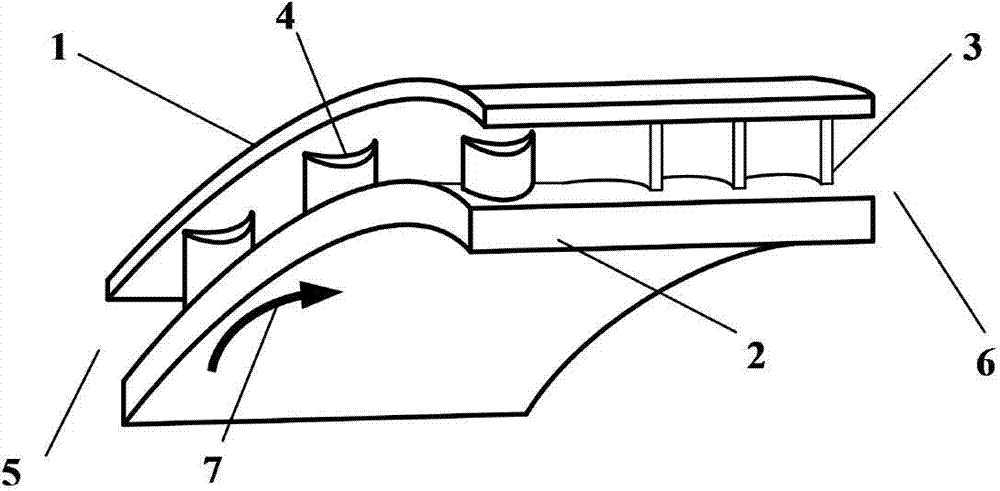

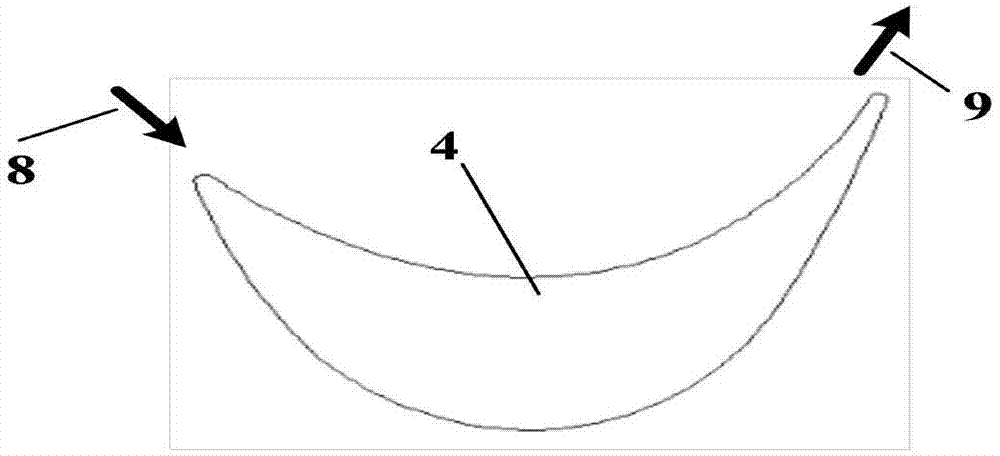

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. Those skilled in the art should understand that the embodiments and accompanying drawings are only for better understanding of the present invention, and are not used to make any limitation. see figure 1 , the turbine according to the present invention includes a cylinder (not shown in the figure) and an impeller (not shown in the figure) arranged in the cylinder and capable of rotating relative to the cylinder, and the tip shroud 2 is arranged around the tip of the impeller. The blade tip shroud 2 and the impeller can be separate parts, and the two are fixed together by welding or other means. A supporting shell 1 is fixedly arranged on the inner surface of the cylinder, and a tip gap is formed between the supporting shell 1 and the tip shroud 2 , and a part of the total airflow flowing through the impeller will flow through the tip gap. A row of cascad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com