Circular inside-release oil pump

An oil pump and ring island technology, which is applied in the field of ring island type internal drain oil pumps, can solve the problems of large volume displacement and stuck pressure limiting valve, etc., achieve large oil discharge and oil discharge flow, avoid wear and deformation, oil discharge and Oil discharge flow and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

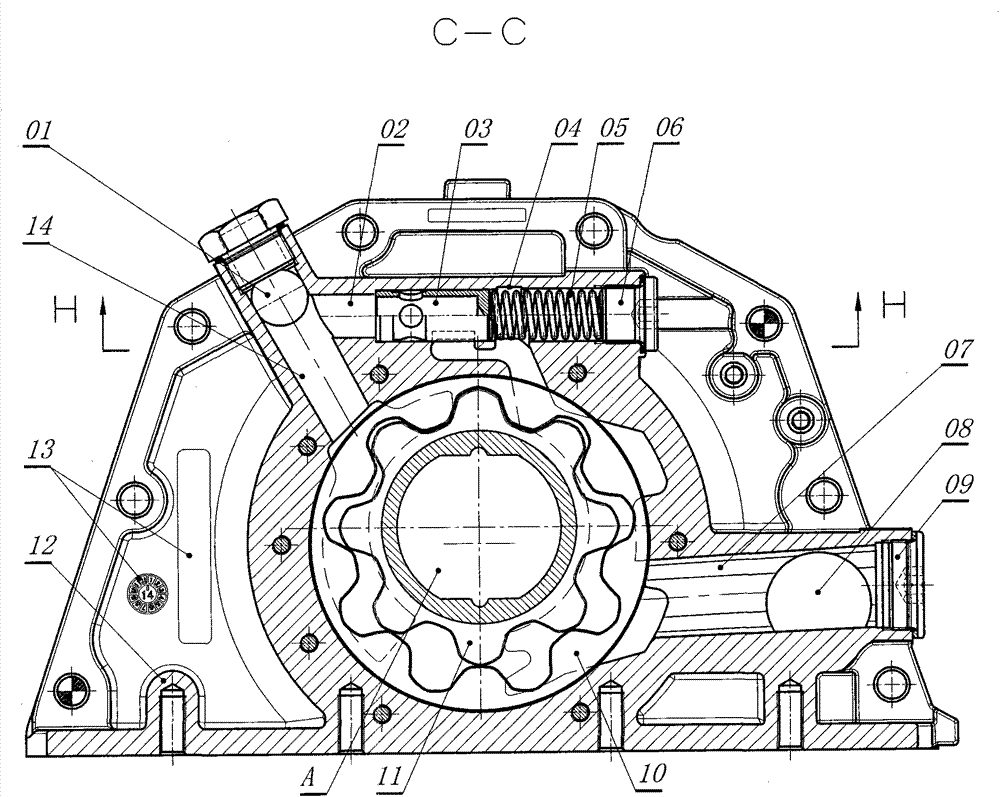

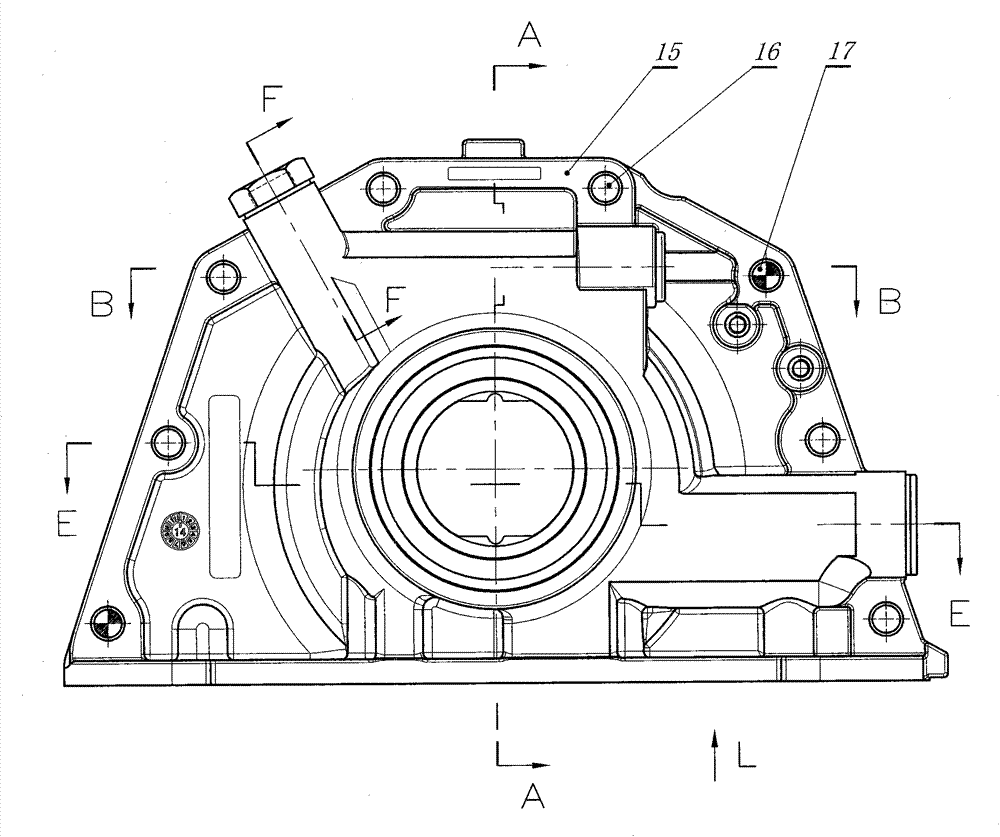

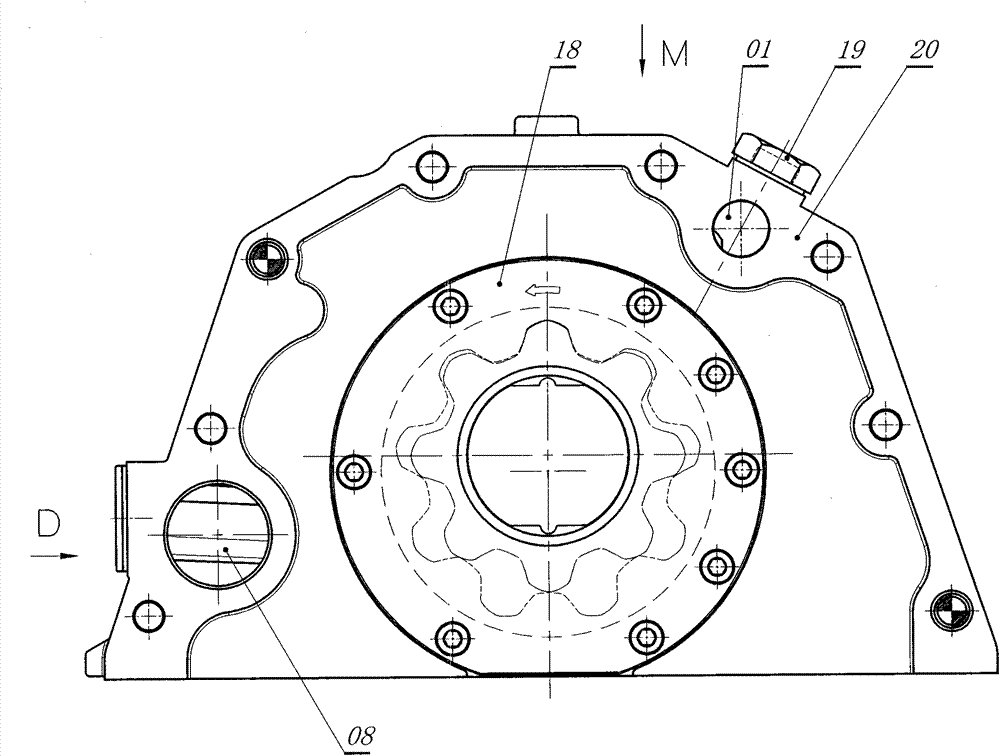

[0051] see figure 1 , 2 . 03), spring (05), end plug (06), seal ring (28) and pump cover (18), the pump body (15) is characterized in that it is provided with an oil inlet hole (07), an oil outlet hole (14), pressure limiting hole (02), internal oil drain passage (22), oil inlet chamber (26), oil outlet chamber (24), rotor hole (31), rotor shaft hole (25), main installation hole ( 16), positioning hole (17), main mounting surface (20), side mounting hole (32), side mounting lip (33), flange (40) and flange hole (30), the oil outlet hole (14 ) and the oil outlet chamber (24), the oil inlet hole (07) and the oil inlet chamber (26) are provided with an oil outlet chamber groove (23) and an oil inlet chamber groove (27), and the side mounting lip (33) is characterized in that four reinforcing ribs (12) are provided on the back side, and the second base surface of the reinforcing ribs (12) is a product identification concave surface (13); the pump cover (18) is characterized in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com