Method for optimizing steam turbine high pressure regulating valve steam inlet sequence testing experiment

A technology of sequential testing and optimization methods, applied in engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as long testing time, shorten testing time, design scientific and reasonable testing steps, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0045] Specific embodiment one: a kind of optimization method of steam turbine high-profile valve intake sequence test test, comprising the following steps:

[0046] Step 1: Obtain the arrangement information of the nozzle group corresponding to the high-profile door of the unit, including the position of the nozzle group corresponding to each high-profile door and the direction of rotor rotation (the direction positioning standard is viewed from the nose to the direction of the generator) and the opening and closing of each pre-opening valve. Spend;

[0047] Step 2: Design an optimized test plan according to the layout information of nozzle groups with different numbers of high-profile doors, optimize the combination of repetitive steps in the traditional test process, and discard some unnecessary repeated opening or repeated closing in multiple groups of tests the process of;

[0048] Step 3: Adjust the operating parameters and control mode of the unit to meet the test cond...

specific Embodiment approach 2

[0050] Specific implementation mode two: the implementation process of step two in this embodiment mode is:

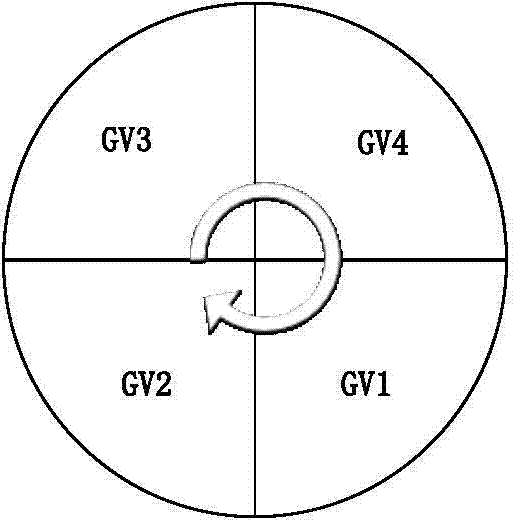

[0051] If the unit has four high-profile doors, taking Figure 1(a) as an example, there are 12 steam intake sequences that can be designed for the unit, of which there are 4 commonly used diagonal steam intake sequences, which are as follows:

[0052] (1) GV1+GV3-GV4-GV2, that is, the first group of test sequences;

[0053] (2) GV1+GV3-GV2-GV4, that is, the second test sequence;

[0054] (3) GV2+GV4-GV3-GV1, namely the third test sequence;

[0055] (4) GV2+GV4-GV1-GV3, that is, the fourth test sequence;

[0056] At present, the commonly used high-profile door switch test process: perform the above four switch tests respectively; and, "+" means joint synchronous opening or closing; "-" means opening or closing; the group "GV1+GV3-GV4-GV2" Take the steam intake sequence as an example. This sequence indicates that when the unit rises from low load to high load, the hig...

specific Embodiment approach 3

[0063] Specific implementation mode three: the implementation process of step two in this embodiment mode is:

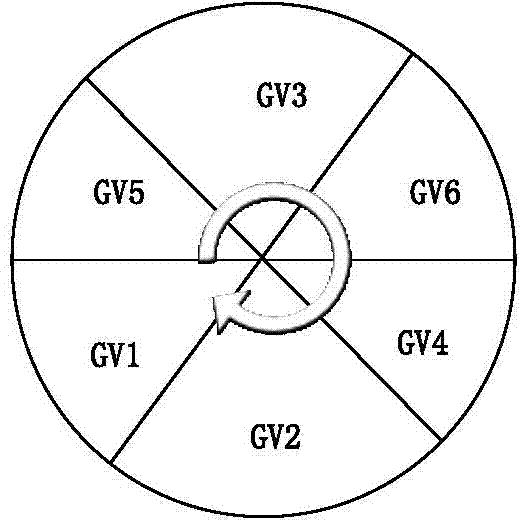

[0064] If the unit has six high-profile doors, taking Figure 1(b) as an example, there are 120 steam intake sequences that can be designed for the unit, of which there are 24 commonly used diagonal steam intake sequences, which are as follows:

[0065] (1) GV2+GV3-GV5-GV4-GV1-GV6, that is, the first group of test sequences;

[0066] (2) GV2+GV3-GV4-GV5-GV1-GV6, that is, the second test sequence;

[0067] (3) GV2+GV3-GV5-GV4-GV6-GV1, namely the third test sequence;

[0068] (4) GV2+GV3-GV4-GV5-GV6-GV1, that is, the fourth test sequence;

[0069] (5) GV5+GV4-GV2-GV3-GV1-GV6, namely the fifth test sequence;

[0070] (6) GV5+GV4-GV3-GV2-GV1-GV6, namely the sixth test sequence;

[0071] (7) GV5+GV4-GV2-GV3-GV6-GV1, that is, the seventh test sequence;

[0072] (8) GV5+GV4-GV3-GV2-GV6-GV1, namely the eighth test sequence;

[0073] (9) GV1+GV6-GV2-GV3-GV5-GV4, that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com