Micro-lens array light guide plate with adaptive spacing

A technology of microlens array and light guide plate, applied in lens, light guide, optics and other directions, can solve the problems of low production precision of light guide plate, low light uniformity, complicated production process, etc. The effect of high light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

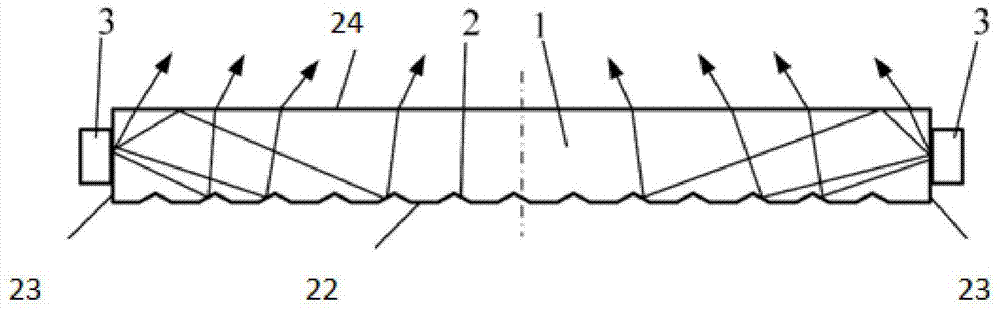

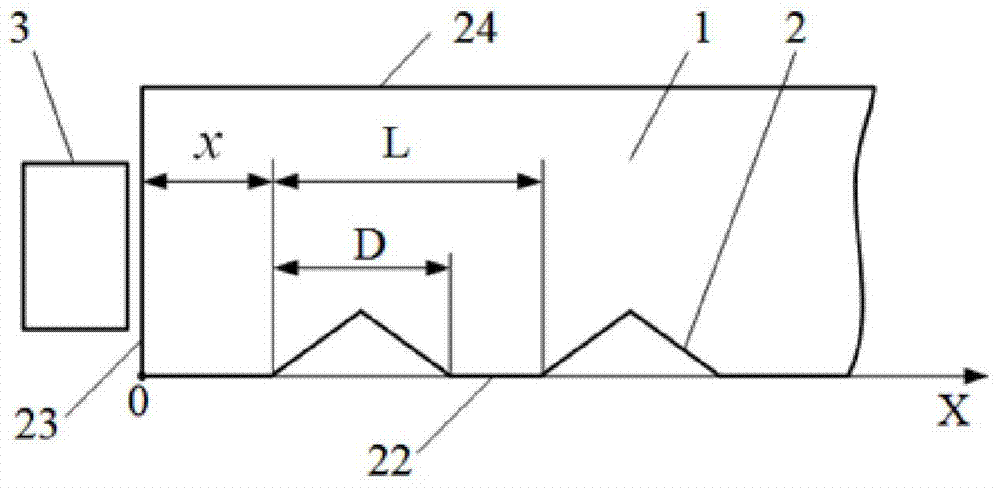

[0029] In one embodiment of the present invention, as figure 1 and figure 2 As shown, a microlens array light guide plate with adaptive spacing includes a light guide plate 1, and the reflective surface 22 of the light guide plate 1 is provided with a number of reflections parallel to each other and parallel to one side of the light guide plate 1 or V-shaped protrusions. The surface lens structure 2, the reflective surface lens structure 2 of this embodiment is V-groove shape, the said reflective surface lens structure 2 is left and right symmetrically distributed with respect to the center line of the light guide plate 1, and the adjacent two reflective surface lens structures 2 The distance d3 is set incrementally from both sides of the light guide plate 11 to the middle of the light guide plate 1, and its value is 30-5000 microns. The material of the light guide plate 1 in this embodiment is an acrylic plate.

[0030] The included angle between the two sides of the reflec...

Embodiment 2

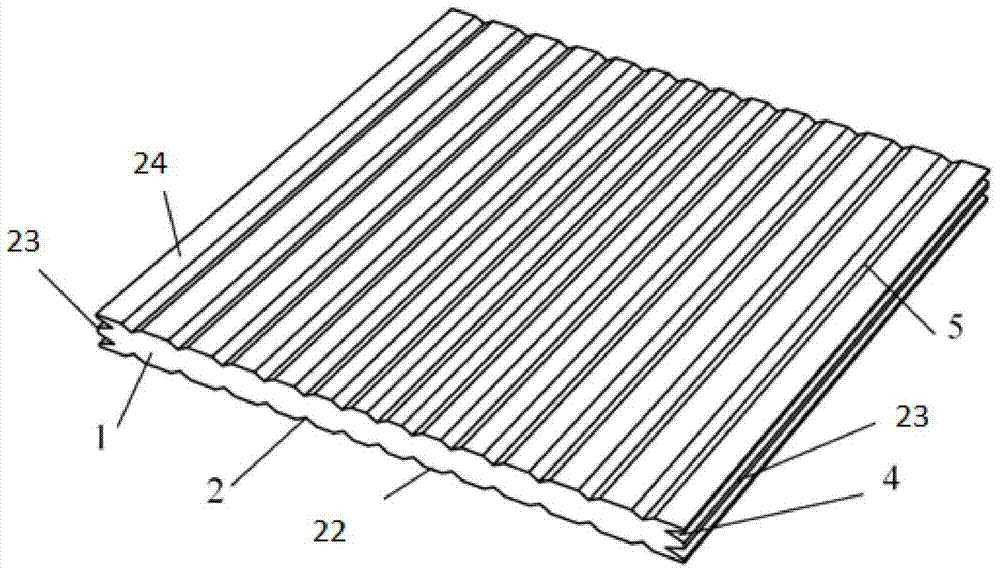

[0034] The difference between this embodiment and Embodiment 1 is that: the light exit surface 24 of the light guide plate 1 is also provided with a number of V-groove or V-protrusion-shaped light exit surface lens structures 5 parallel to each other and one side of the light guide plate 1 at the same time, In this embodiment, V-groove-shaped lens structures 5 on the light-emitting surface are used. The lens structures 5 on the light-emitting surface are distributed at equal intervals, and the distance d1 between adjacent lens structures 5 on the light-emitting surface is 30-2000 microns.

[0035] The included angle between the two sides of the light-emitting surface lens structure 5 is 30-170 degrees, and the depth or height is 0.01-0.2 mm.

[0036] In this embodiment, a V-groove-shaped light-emitting surface lens structure 5 is provided on the light-emitting surface 24 to further play the role of scattering light and improve the light-guiding efficiency, light-emitting unifor...

Embodiment 3

[0038] like image 3As shown, the difference between this embodiment and the second embodiment is that: the light incident side 23 of the light guide plate 1 is also provided with a number of V-groove-shaped or V-shaped light incident surfaces parallel to one side of the light guide plate 1 at the same time. Surface lens structures 4, the light incident surface lens structures 4 are equally spaced, and the distance d2 between adjacent light incident surface lens structures 4 is 30-2000 microns.

[0039] The included angle between the two sides of the light incident surface lens structure 4 is 30-170 degrees, and the depth or height is 0.01-0.2 mm.

[0040] like image 3 As shown, the V-groove-shaped reflective surface lens structure 2 on the reflective surface 22 of the light guide plate 1 and the V-groove-shaped light-exit surface lens structure 5 on the light-exit surface 24 are distributed in an array, and both are parallel to an edge line on the surface of the light guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com