Analysis method for optimizing gas turbine overhaul and maintenance scheme

A technology of gas turbine and analysis method, which is applied in the direction of data processing application, prediction, calculation, etc., to achieve the effect of overcoming unreasonable settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

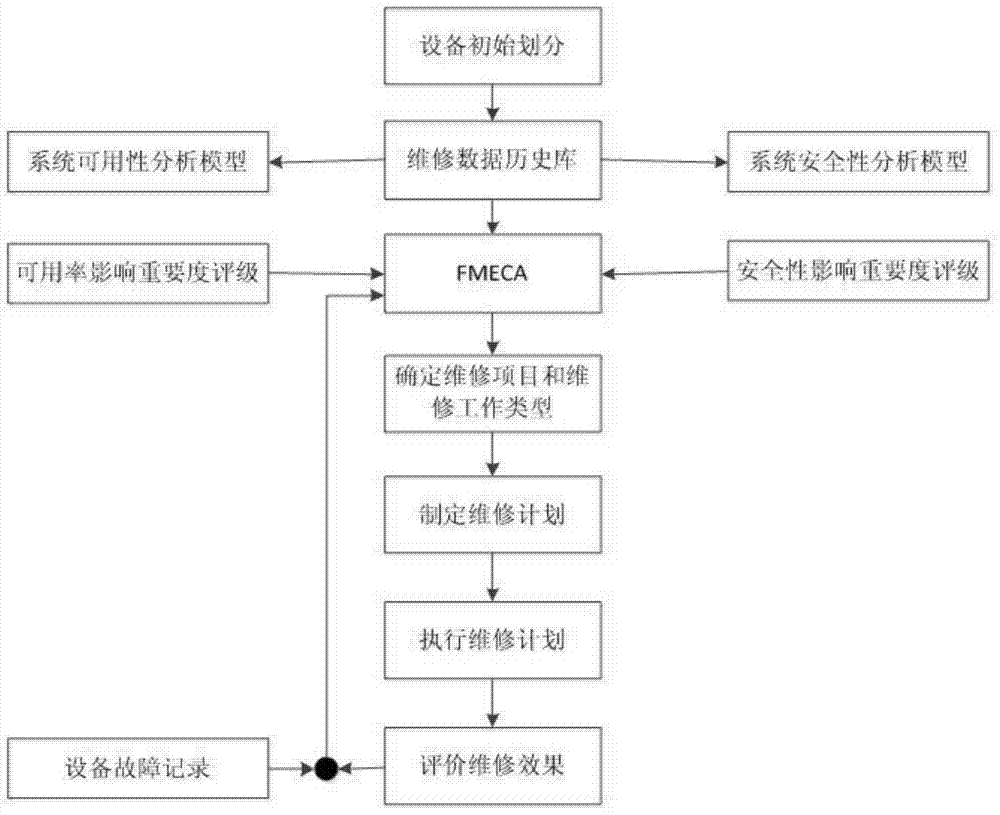

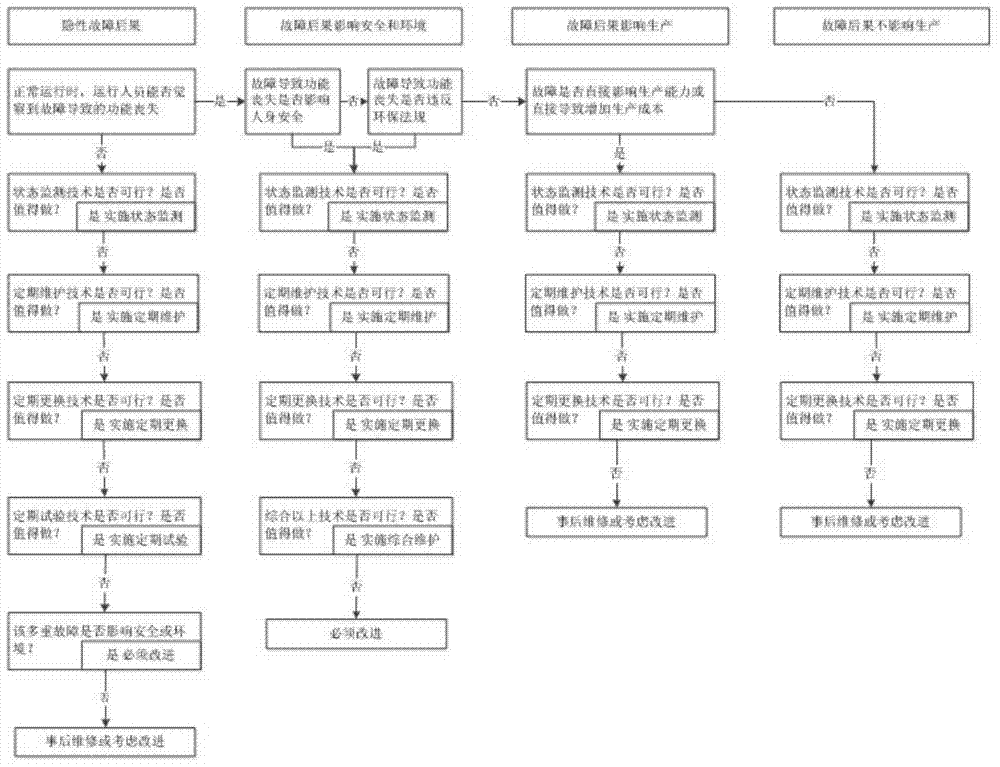

Method used

Image

Examples

example (2

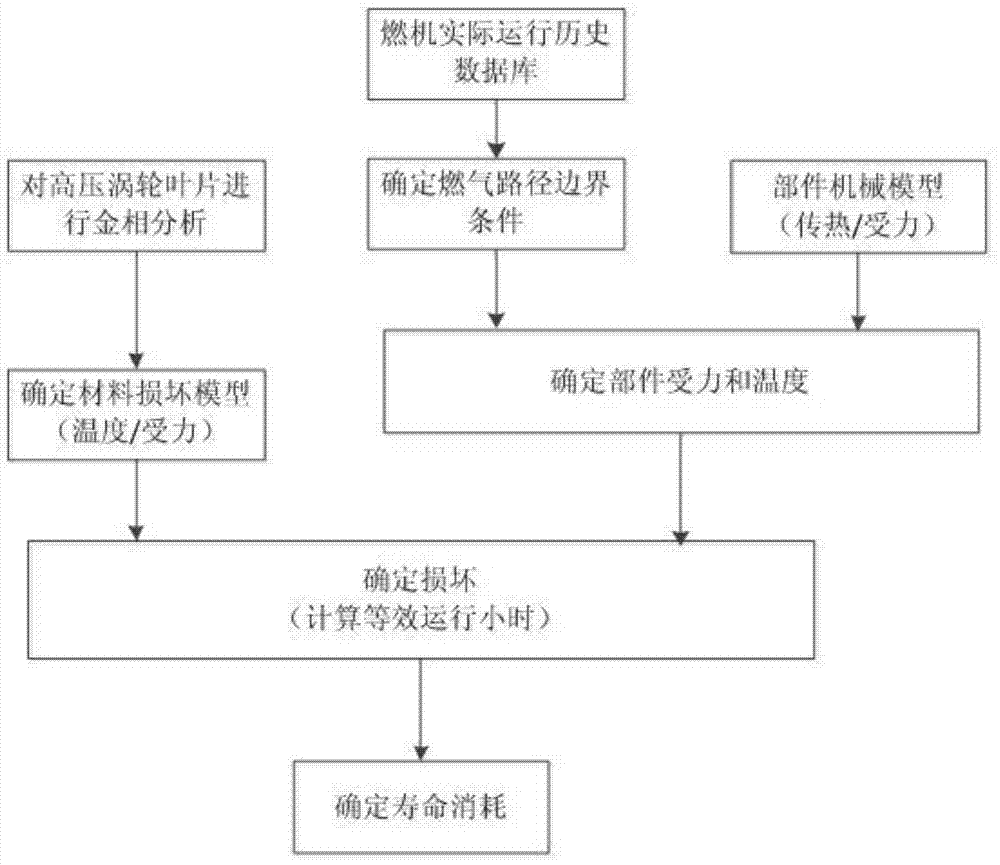

[0114] The overhaul of gas turbines is expensive. As the hot end part, the blades are the key components of gas turbines. Long-term operation under severe conditions such as high temperature, high pressure, and corrosive media is a key factor restricting the performance and life of gas turbines, and maintenance is very expensive. In gas turbines It occupies a relatively large proportion in the cost of major and medium repairs.

[0115] Since the gas turbine does not operate completely at full load, and the overhaul period of the gas turbine is considered according to the full load, there is a certain room for extension of the overhaul period, which can reduce the overhaul cost. In order to quantify the extended time of the overhaul period, this patent adopts the method of quantifying the life of the hot end parts of the gas turbine to calculate the overhaul period of the gas turbine. Since high temperature blades are the limiting factor for the life of gas turbines, it is feas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com