Preparation method of nickel cobalt aluminum lithium battery positive electrode material and lithium battery positive electrode material

A cathode material, lithium battery technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of low compaction density of nickel-cobalt-aluminum lithium battery cathode materials, and achieve easy industrialization promotion and production control, anti-fading Strong, strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

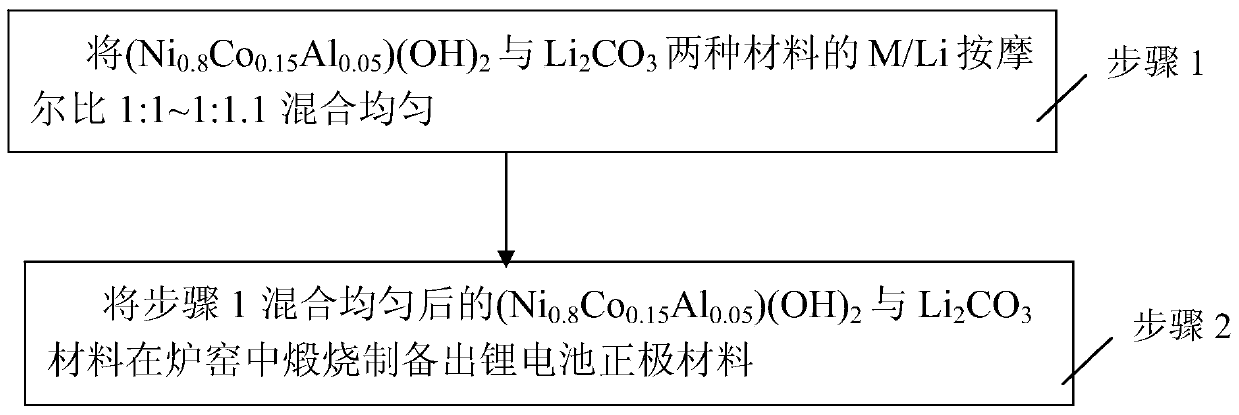

[0023] In the preferred technical scheme of the present invention, the nickel-cobalt-aluminum Li(Ni 0.8 co 0.15 al 0.05 )O 2 The preparation method of cathode material comprises the following steps (see figure 1 ):

[0024] Step 1: put (Ni 0.8 co 0.15 al 0.05 )(OH) 2 with Li 2 CO 3 The two materials are mixed evenly according to the M / Li molar ratio of 1:1.02~1:1.03, where M means (Ni 0.8 co 0.15 al 0.05 )(OH) 2 ;

[0025] Step 2: (Ni 0.8 co 0.15 al 0.05 )(OH) 2 with Li 2 CO 3 The material is calcined in a kiln to prepare the lithium battery positive electrode material.

[0026] In addition, in addition to including (Ni 0.8 co 0.15 al 0.05 )(OH) 2 with Li 2 CO 3 In addition to materials, it also includes Li(Ni 0.8 co 0.15 al 0.05 )O 2 The primary particle growth effect and the trace doping elements affected by the degree of compactness between primary particles.

[0027] Preferably, the doping element is Ti, M g , the blending amount accounts fo...

Embodiment 1

[0035] According to the molar ratio of M / Li 1:1.02, the nickel-cobalt-aluminum (Ni 0.8 co 0.15 al 0.05 )(OH) 2 Hydroxide and Li 2 CO 3 , (Ni 0.8 co 0.15 al 0.05 )(OH) 2 D50 of 9.6 µm, Li 2 CO 3 The D50 is 5.2 microns, (Ni 0.8 co 0.15 al 0.05 )(OH) 2 Hydroxide and Li 2 CO 3 Mix evenly in a high-mixer first, then put it into a kiln for sintering, raise it to 950°C at 3°C / min, adjust the atmosphere during the sintering process, keep it warm for 12 hours, and then cool with the furnace. The sintered material is sieved to obtain this product. The cathode composite material in the invention (see figure 2 ).

[0036] The cathode material of this example, the binder PVDF, the solvent NMP and the conductive agent were stirred evenly to prepare the cathode slurry, and the cathode slurry was uniformly coated on both sides of the aluminum foil, rolled and cut to obtain the cathode sheet. Test the maximum compaction density of the positive electrode sheet. Using artific...

Embodiment 2

[0038] Weigh M according to the molar ratio of M / Li 1:1.03 g Nickel-cobalt-aluminum (Ni 0.8 co 0.15 al 0.05 )(OH) 2 Hydroxide and Li 2 CO 3 , (Ni 0.8 co 0.15 al 0.05 )(OH) 2 D50 of 9.6 µm, Li 2 CO 3 The D50 is 5.2 microns, (Ni 0.8 co 0.15 al 0.05 )(OH) 2 Hydroxide and Li 2 CO 3 Mix evenly in a high-mixer first, then put it into a kiln for sintering, raise it to 950°C at 3°C / min, adjust the atmosphere during the sintering process, keep it warm for 12 hours, and then cool with the furnace. The sintered material is sieved to obtain this product. The cathode composite material in the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com