Method and system for driving rotation of stepping motor

A technology for stepping motors and driving steps, applied in the direction of motor generator control, control systems, electrical components, etc., can solve problems such as unfavorable stepping motor transitions, complicated driving methods, etc., and achieve the effect of easy control and simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

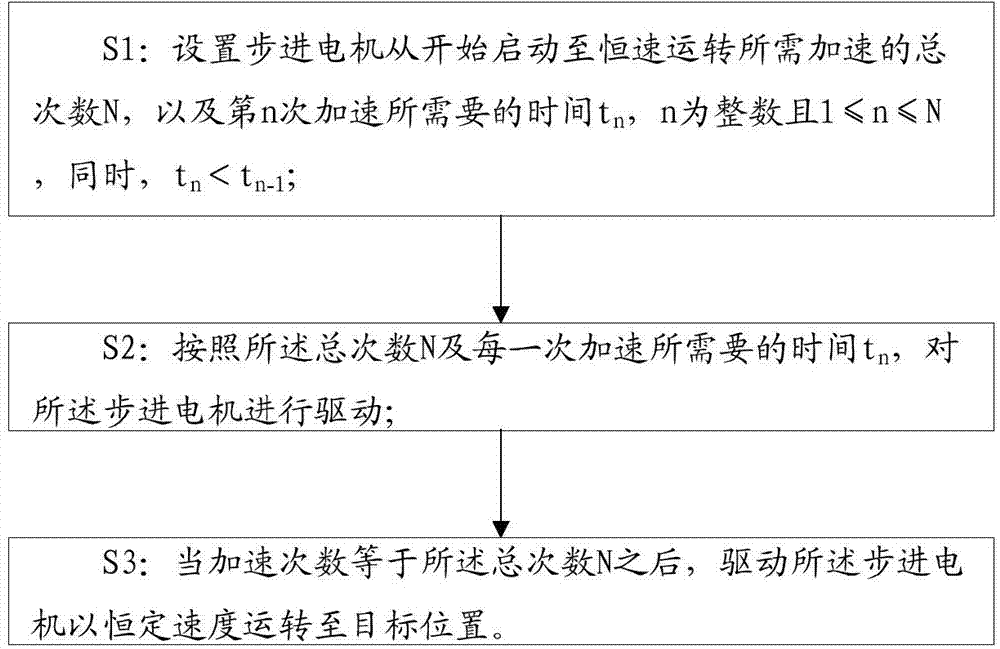

[0053] This embodiment provides a method for driving a stepping motor to rotate, see figure 1 shown, including the following steps:

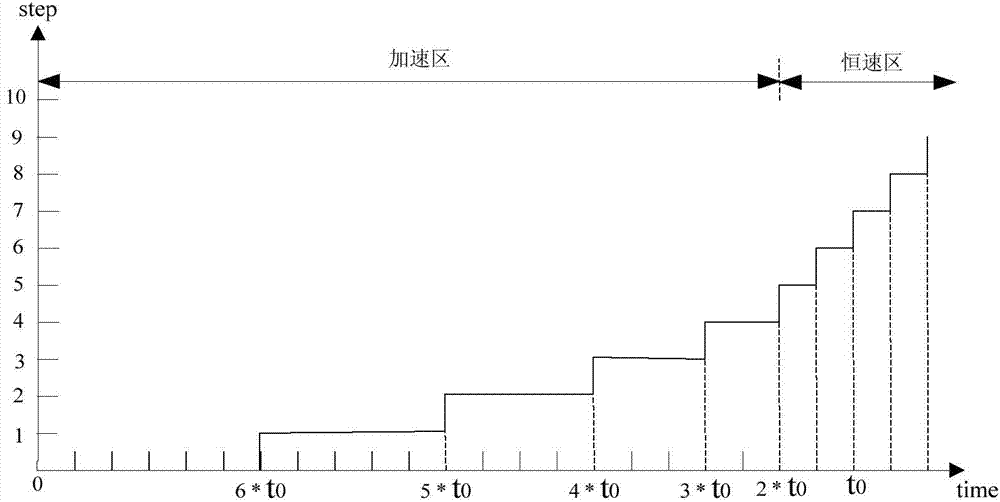

[0054] S1: Set the total number N of accelerations required for the stepping motor from start to constant speed operation, and the time t required for the nth acceleration n , n is an integer and 1≤n≤N, meanwhile, t n n-1 . The larger the value of N, the smoother the acceleration process of the stepping motor, but considering the time required to reach a constant speed operation and the memory of the processor driving the acceleration process of the stepping motor, the value of N is generally : 5≤N≤10. set t n n-1 It is guaranteed that as the stepper motor accelerates, when n is closer to N, the time t required for the nth acceleration n shorter.

[0055] S2: According to the total number of times N and the time t required for each acceleration n , to drive the stepper motor.

[0056] S3: After the number of times of acceleration is equa...

Embodiment 2

[0075] A system for driving a stepper motor to rotate provided by this embodiment, see Figure 4 shown, including:

[0076] The data setting module is used to set the total number of acceleration times N required for the motor to run at a constant speed from the start, and the time t required for the nth acceleration n , n is an integer and 1≤n≤N, meanwhile, t n n-1 ;

[0077] Acceleration drive signal output module, used for according to the total number of times N and the time t required for each acceleration n , to drive the motor;

[0078] The constant speed drive signal output module is used to drive the motor to the target position at a constant speed after the number of accelerations is equal to the total number of times N.

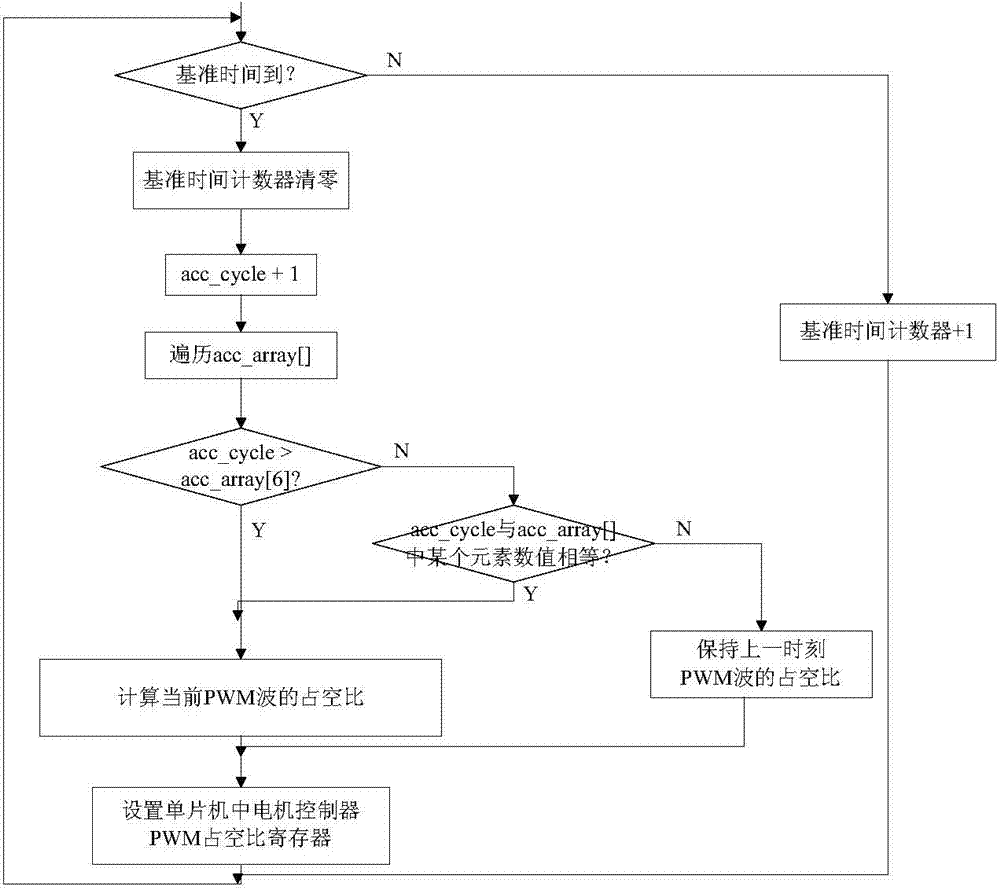

[0079] As a preferred solution, on the basis of the above solution, the data setting module specifically includes: a reference time setting submodule and an acceleration array setting submodule, wherein the reference time setting submodule is u...

Embodiment 3

[0085] This embodiment provides a method for driving a stepper motor to rotate by using a central processing unit in a digital instrument. The central processing unit uses the method for driving a stepper motor described in Embodiment 1 to output a driving pulse signal to drive a stepper motor. Wherein said central processing unit is MC9S12H256 chip, and it has 24 PWM output ports, wherein 4 PWM output ports are connected with the voltage input end of the stator magnetic field coil of a stepper motor to be driven as the output end of drive pulse signal, this It can drive 6 stepping motors at the same time, which can well meet the number of motors that need to be driven on the pointer instrument panel in the digital instrument.

[0086] Such as Figure 5 A schematic diagram of the circuit connection between the MC9S12H256 chip and the stepping motor is given.

[0087] Figure 5 The shown M0C0M / PU0, M0C0P / PU1, M0C1M / PU2, M0C1P / PU3 are the first group, which are connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com