A kind of production method of Moringa walnut milk

A production method and technology of walnut milk, applied in the field of vegetable protein beverage processing, can solve the problems of insufficient stability of walnut milk, damage to human health, and damage to health, and achieve the goal of being easy to popularize and apply, supplementing various nutrients, and enhancing immunity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

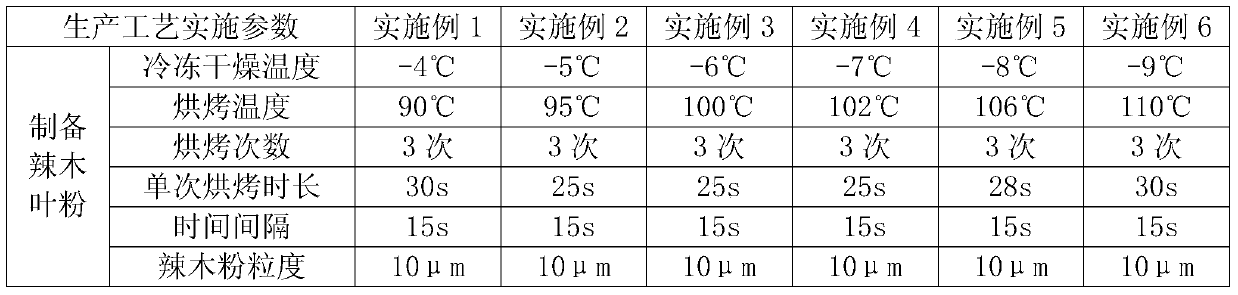

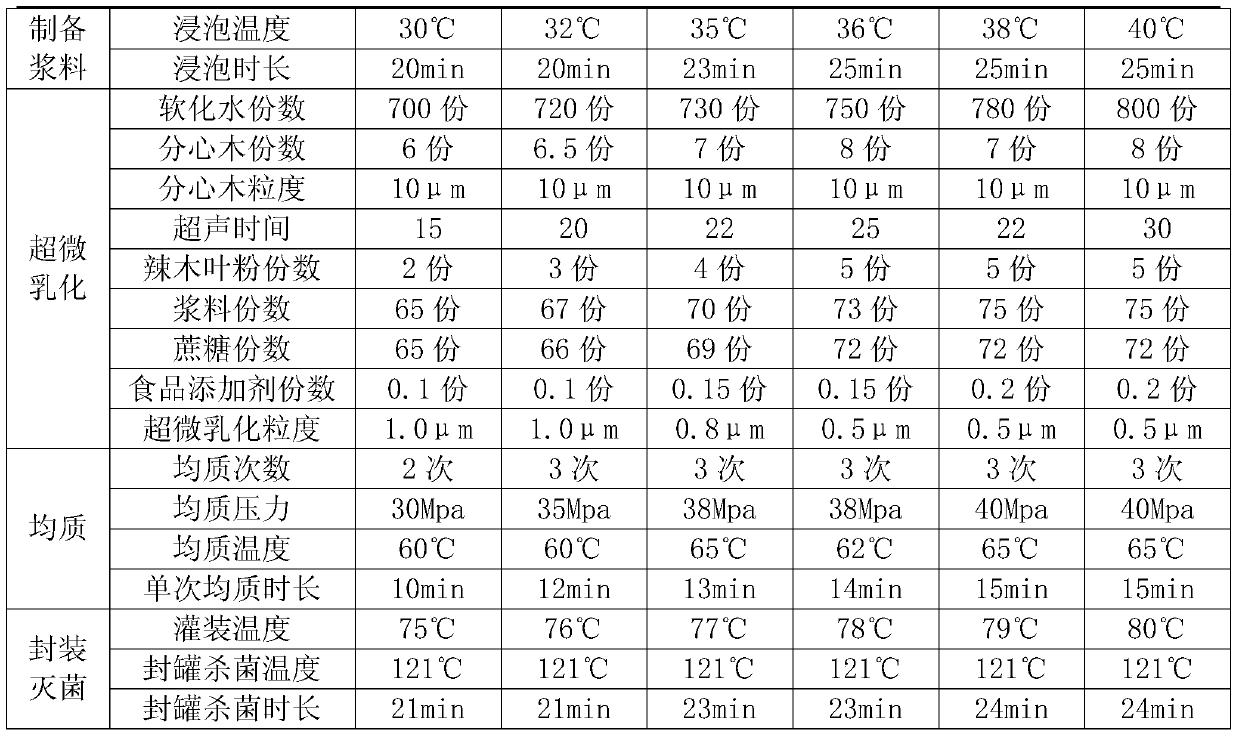

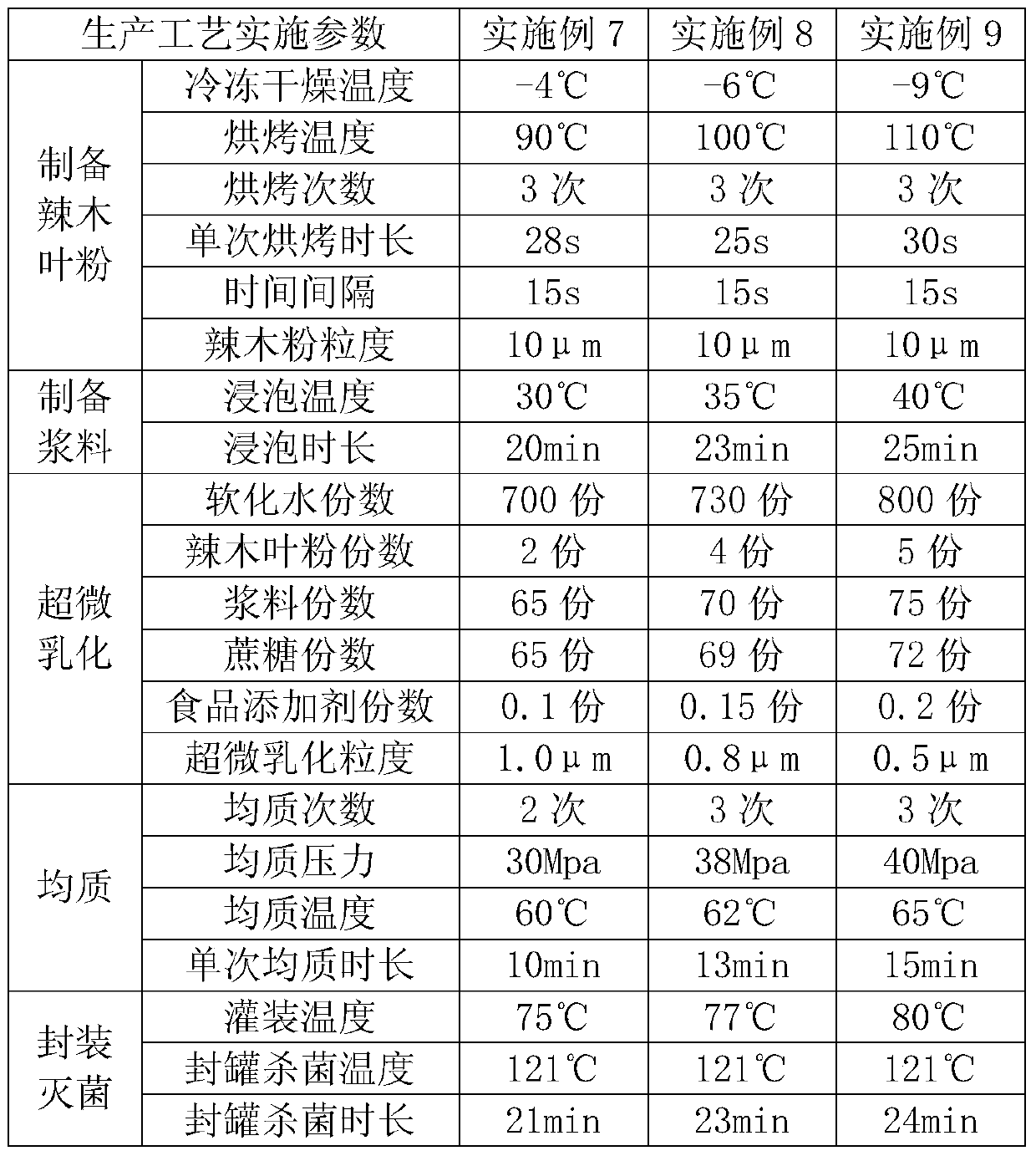

[0026] A kind of production method of Moringa walnut milk, comprises the steps:

[0027] Step (1), freeze-dry the fresh leaves of Moringa oleifera, then increase the fragrance to remove the green and astringent taste and grassy smell of the leaves of Moringa oleifera, and bake them in an oven at a temperature of 90°C in 3 times, each time lasting The time is 30s, the interval is 15s, and the obtained Moringa leaves are ultrafinely pulverized to obtain Moringa leaf powder with a particle size of less than 10 μm; the freeze-drying is vacuum freeze-drying at a temperature of -4°C.

[0028] Step (2): Select mature, plump walnut kernels with milky white or yellowish cross-section, no smell, mildew, or moth-eaten walnut kernels, soak in 30°C water for 20 minutes after rinsing, and then peel the skins to obtain peeled walnut kernels Carrying out refining treatment to obtain slurry;

[0029] In step (3), according to the weight fraction, after 6 parts of split woods are air-pulverize...

Embodiment 2

[0033] Step (1), after freeze-drying the fresh Moringa leaves, enhance the aroma to remove the green and grassy smell of Moringa leaves, and bake them in an oven at a temperature of 95°C in 3 times, each time lasting The time is 25s, the interval is 15s, and the obtained Moringa leaves are ultrafinely pulverized to obtain Moringa leaf powder with a particle size of less than 10 μm; the freeze-drying is vacuum freeze-drying at a temperature of -5°C.

[0034] In step (2), select mature, plump walnut kernels with milky white or yellowish cross-section, no smell, mildew, or moth-eaten, rinse and soak in water at 32°C for 20 minutes, and then peel the skins to obtain peeled walnut kernels Carrying out refining treatment to obtain slurry;

[0035] In step (3), according to the weight fraction, 6.5 parts of centipede are air-pulverized to a particle size of less than 10 μm, then added to 720 parts of demineralized water and ultrasonicated for 20 minutes, filtered, and then the Moring...

Embodiment 3

[0039] A kind of production method of Moringa walnut milk, comprises the steps:

[0040] Step (1), freeze-dry the fresh leaves of Moringa oleifera, then increase the fragrance to remove the green and grassy smell of leaves of Moringa oleifera, and bake them in an oven at a temperature of 100°C in 3 times, each time lasting The time is 25s, and the interval is 15s. The obtained Moringa leaves are ultrafinely pulverized to obtain Moringa leaf powder with a particle size of less than 10 μm; the freeze-drying is vacuum freeze-drying at a temperature of -6°C.

[0041] Step (2): Select mature, plump walnut kernels with milky white or yellowish cross-section, no smell, mildew, or moth-eaten walnut kernels, soak in 35°C water for 23 minutes after rinsing, and then peel the skins to obtain peeled walnut kernels Carrying out refining treatment to obtain slurry;

[0042]In step (3), according to the weight fraction, after 7 parts of split woods are air-pulverized to a particle size of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com