Spray device and cleaning equipment

A technology of spraying device and cleaning agent, applied in the direction of cleaning flexible articles, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inability to achieve uniform pressure, uneven spraying pressure, poor display substrate, etc. The effect of uneven spray pressure, improved yield and uniform impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

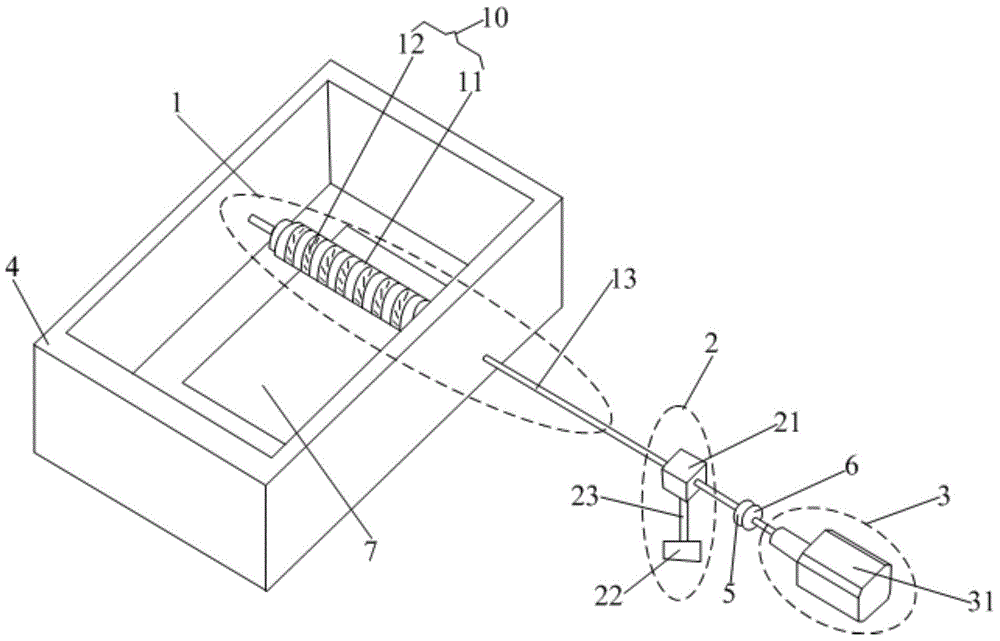

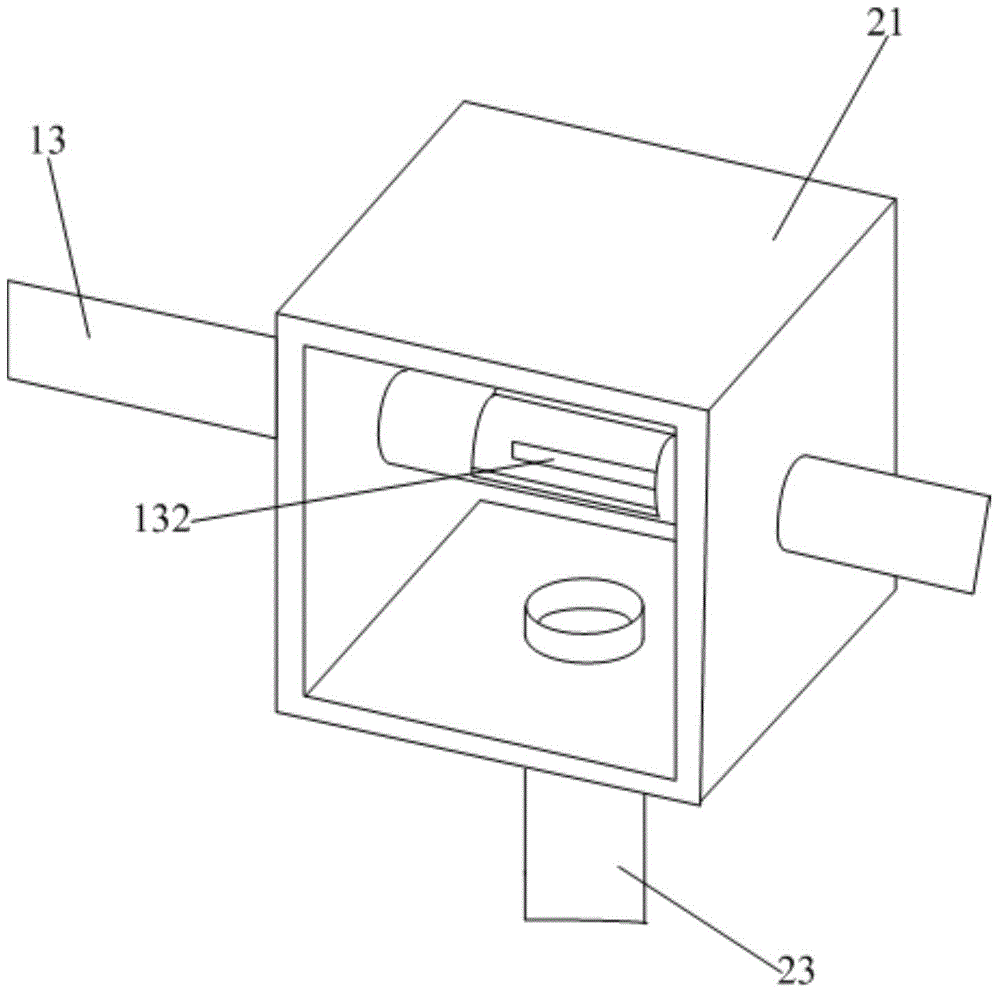

[0031] This embodiment provides a spraying device, such as Figure 1-Figure 3 As shown, it includes a working unit 1, a supply unit 2 and a driving unit 3. The working unit 1 is used to rotate and spray cleaning agent to clean the substrate 7 to be cleaned; the supply unit 2 is used to provide cleaning agent for the working unit 1; the driving unit 3 is used to provide rotating power for the working unit 1.

[0032] By setting the working unit 1 capable of rotating and spraying, the spraying pressure of the cleaning agent is uniform when the spraying device is spraying, so that the surface of the substrate 7 to be cleaned is uniformly impacted by the spraying of the cleaning agent, thereby avoiding spraying. Defects caused by uneven pressure.

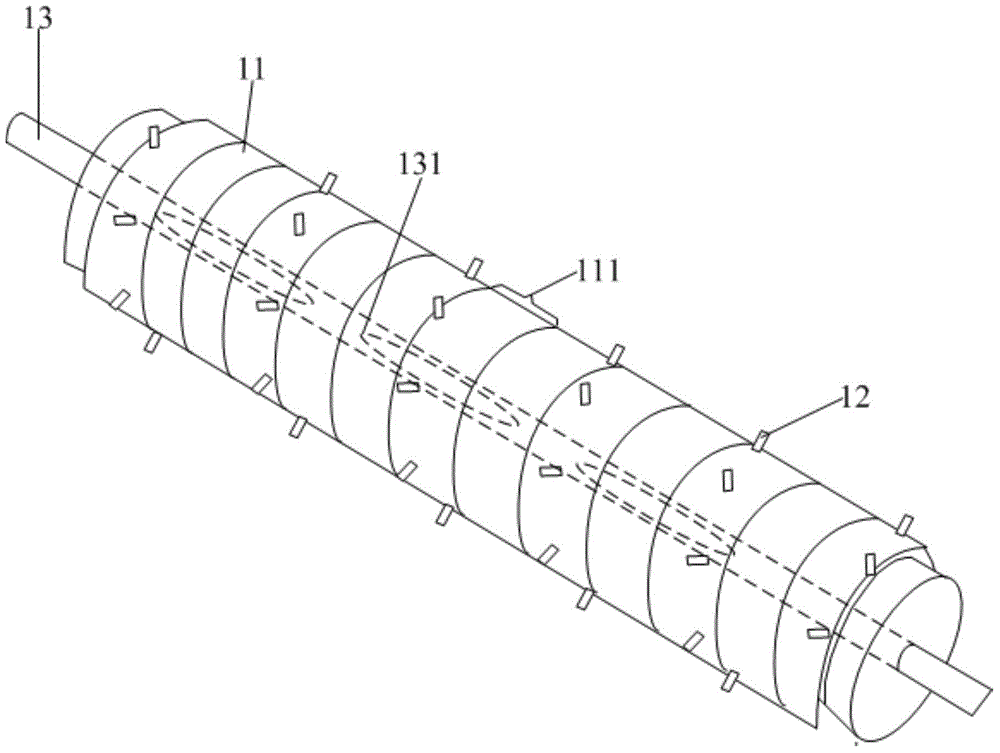

[0033] In this embodiment, the working unit 1 includes a spraying part 10 and a rotating shaft 13, the spraying part 10 is used to rotate under the drive of the rotating shaft 13, and spray cleaning agent to the substrate 7 to be clean...

Embodiment 2

[0046] This embodiment provides a cleaning device, including the spray device in Embodiment 1. The cleaning equipment is suitable for high-pressure cleaning of finished or semi-finished display substrates or other plate products during the production process of display products. The cleaning equipment can also be used in other fields that require high-pressure cleaning, such as high-pressure cleaning of cars. The cleaning equipment can make the high-pressure spraying of the cleaning agent more uniform, so as to achieve a better cleaning effect.

[0047] By adopting the shower device in Embodiment 1, the yield rate of the substrate cleaned by the cleaning equipment is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com