Zirconium oxide ceramic injection molding device and control method thereof

A zirconia ceramics, injection molding technology, applied in the field of zirconia ceramics, can solve the problems of uneven injection, low production efficiency, easy cooling of prepared materials, etc., to achieve uniform injection, reduce heat loss, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

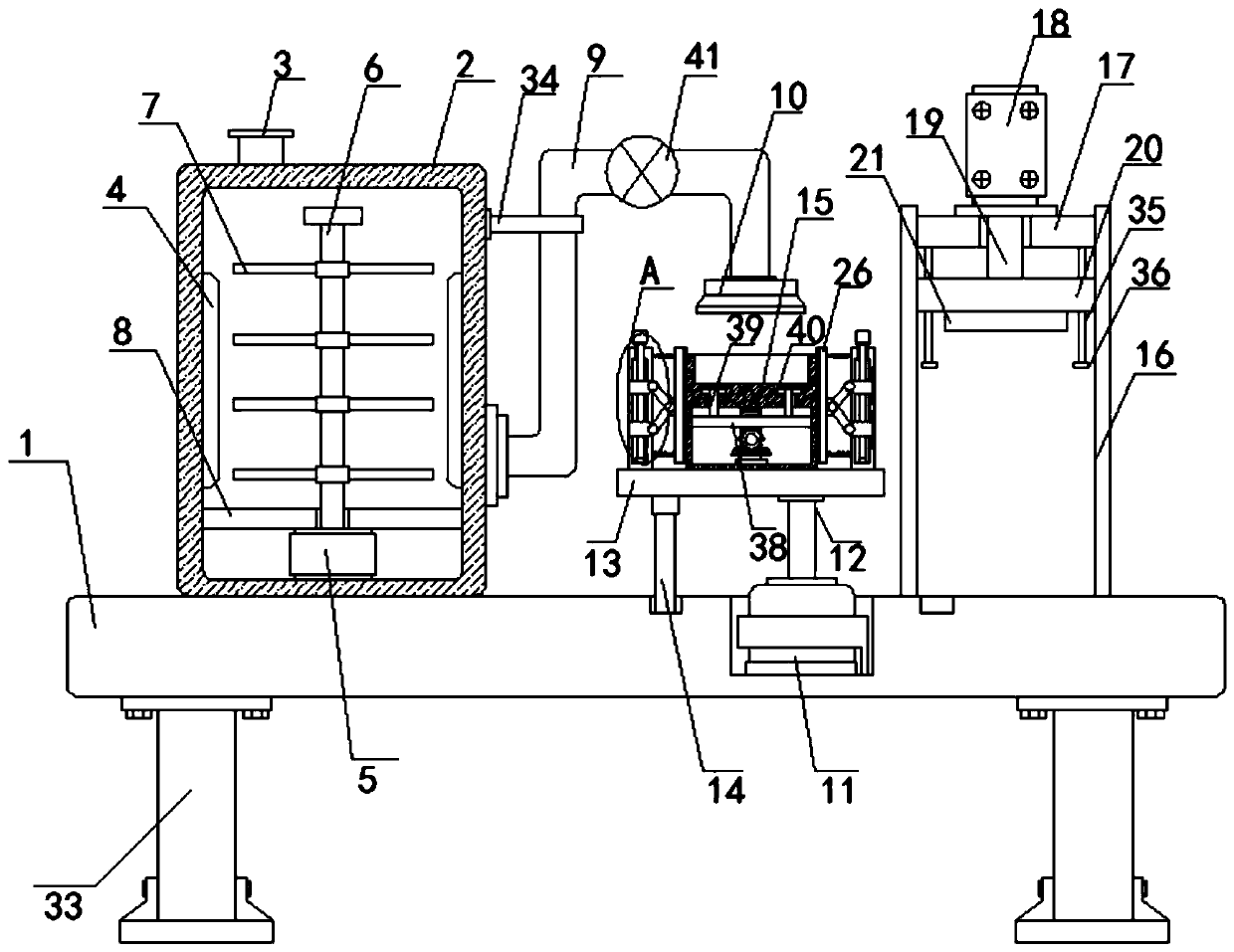

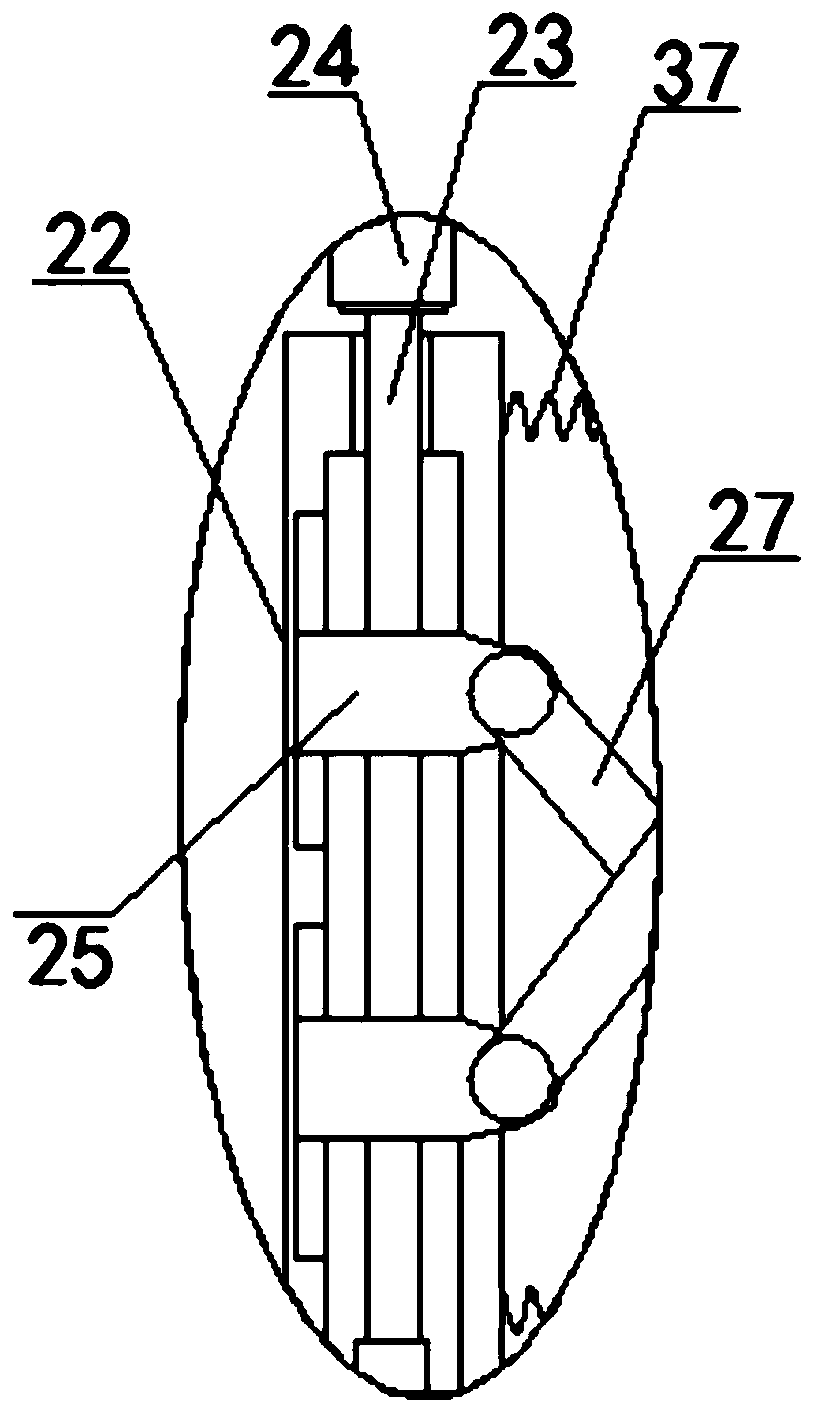

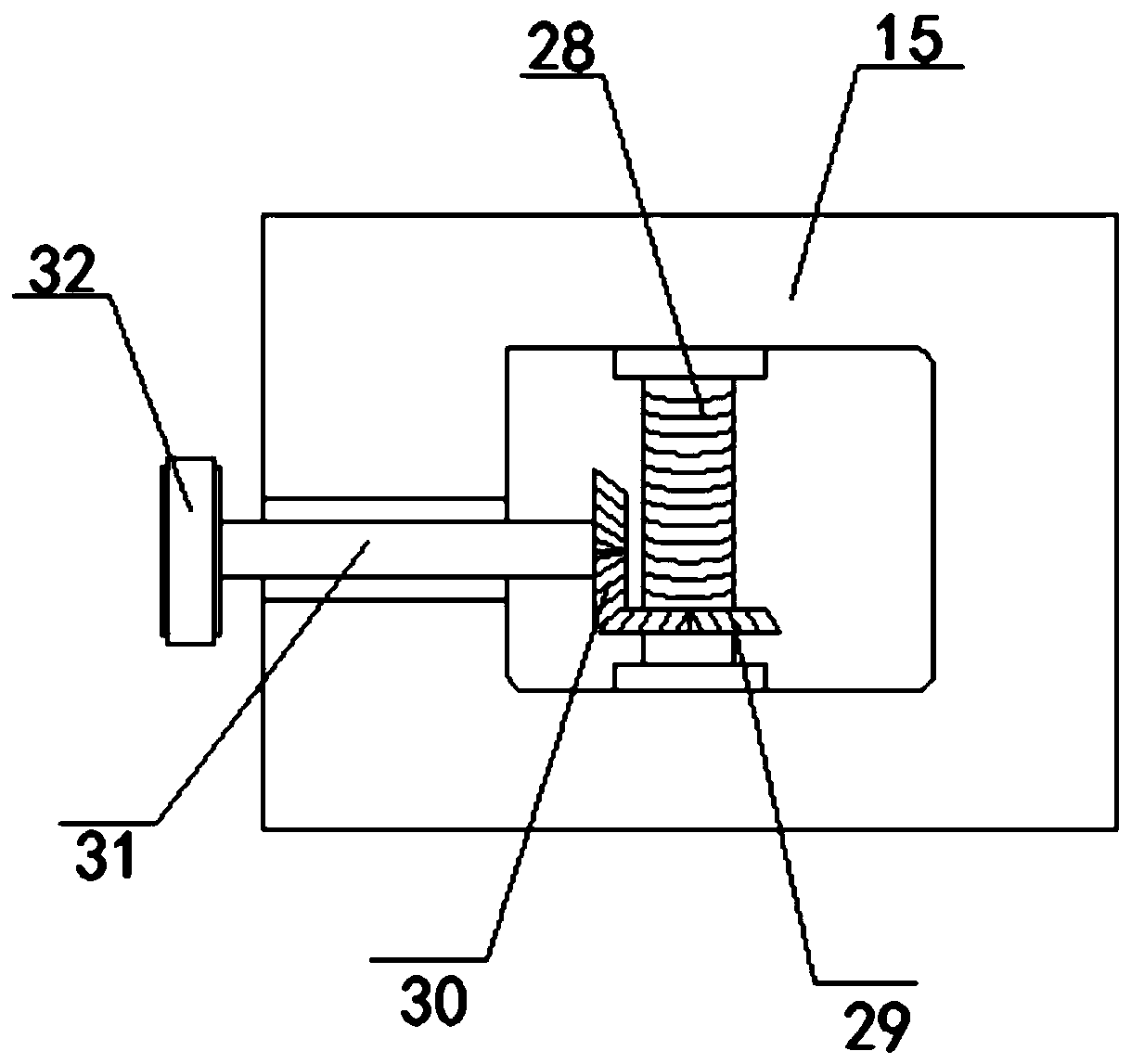

[0028] Such as figure 1 and Figure 4 , a zirconia ceramic injection molding device and method of use, comprising a support base 1, the top of one side of the support base 1 is fixedly connected with an injection box 2, the top of the injection box 2 is inserted with an injection hopper 3, the injection box Heating plates 4 are arranged on the inner walls of both sides of 2, and a first motor 5 is arranged in the injection box 4. The output end of the first motor 5 is fixedly connected with a rotating shaft 6, and a plurality of stirring rods are fixedly connected on the rotating shaft 6. 7. One side of the injection box 2 is inserted with a feeding pipe 9, and the end of the feeding pipe 9 away from the injection box 2 is provided with a material head 10, the feeding pipe 9 is provided with a control valve 41, and the support seat 1 is provided with a mounting groove. A second motor 11 is arranged in the installation groove, the output end of the second motor 11 is fixedly c...

Embodiment 2

[0031] Such as figure 1 and Figure 4, a zirconia ceramic injection molding device and method of use, comprising a support base 1, the top of one side of the support base 1 is fixedly connected with an injection box 2, the top of the injection box 2 is inserted with an injection hopper 3, the injection box Heating plates 4 are arranged on the inner walls of both sides of 2, and a first motor 5 is arranged in the injection box 4. The output end of the first motor 5 is fixedly connected with a rotating shaft 6, and a plurality of stirring rods are fixedly connected on the rotating shaft 6. 7. One side of the injection box 2 is inserted with a feeding pipe 9, and the end of the feeding pipe 9 away from the injection box 2 is provided with a material head 10, the feeding pipe 9 is provided with a control valve 41, and the support seat 1 is provided with a mounting groove. A second motor 11 is arranged in the installation groove, the output end of the second motor 11 is fixedly co...

Embodiment 3

[0050] Such as figure 1 and Figure 4 , a zirconia ceramic injection molding device and method of use, comprising a support base 1, the top of one side of the support base 1 is fixedly connected with an injection box 2, the top of the injection box 2 is inserted with an injection hopper 3, the injection box Heating plates 4 are arranged on the inner walls of both sides of 2, and a first motor 5 is arranged in the injection box 4. The output end of the first motor 5 is fixedly connected with a rotating shaft 6, and a plurality of stirring rods are fixedly connected on the rotating shaft 6. 7. One side of the injection box 2 is inserted with a feeding pipe 9, and the end of the feeding pipe 9 away from the injection box 2 is provided with a material head 10, the feeding pipe 9 is provided with a control valve 41, and the support seat 1 is provided with a mounting groove. A second motor 11 is arranged in the installation groove, the output end of the second motor 11 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com