Spinning device

A technology of spinning equipment and spinning wheel, which is applied in the field of pressure processing of metal pipes, can solve the problems of lowering the head of the mold, difficulty in demoulding the ultra-long and thin-walled cylindrical parts, and torsional deformation of the workpiece, and achieves the effect of small processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

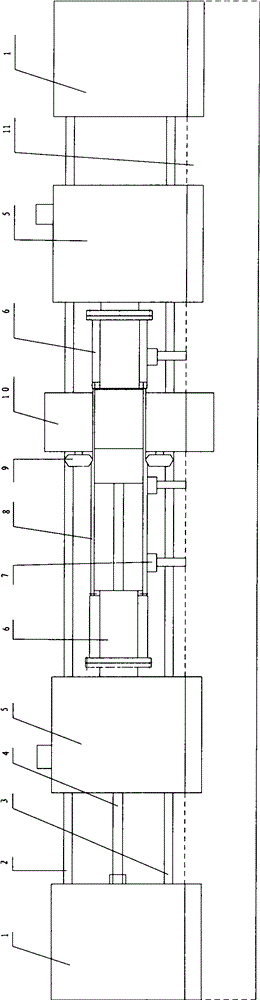

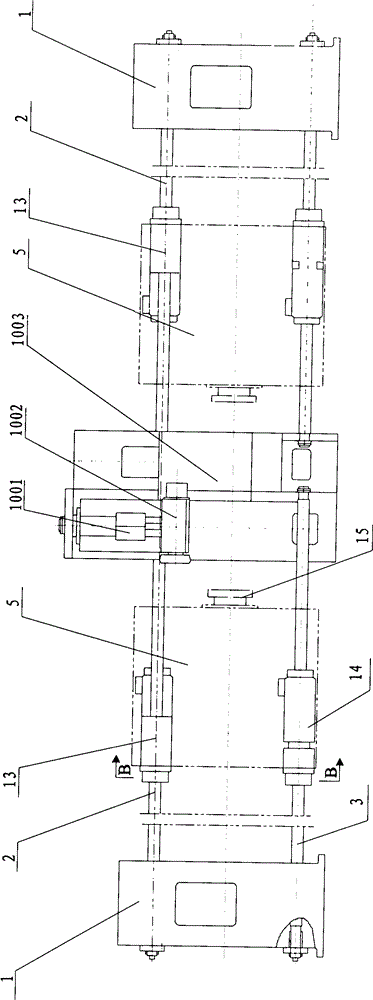

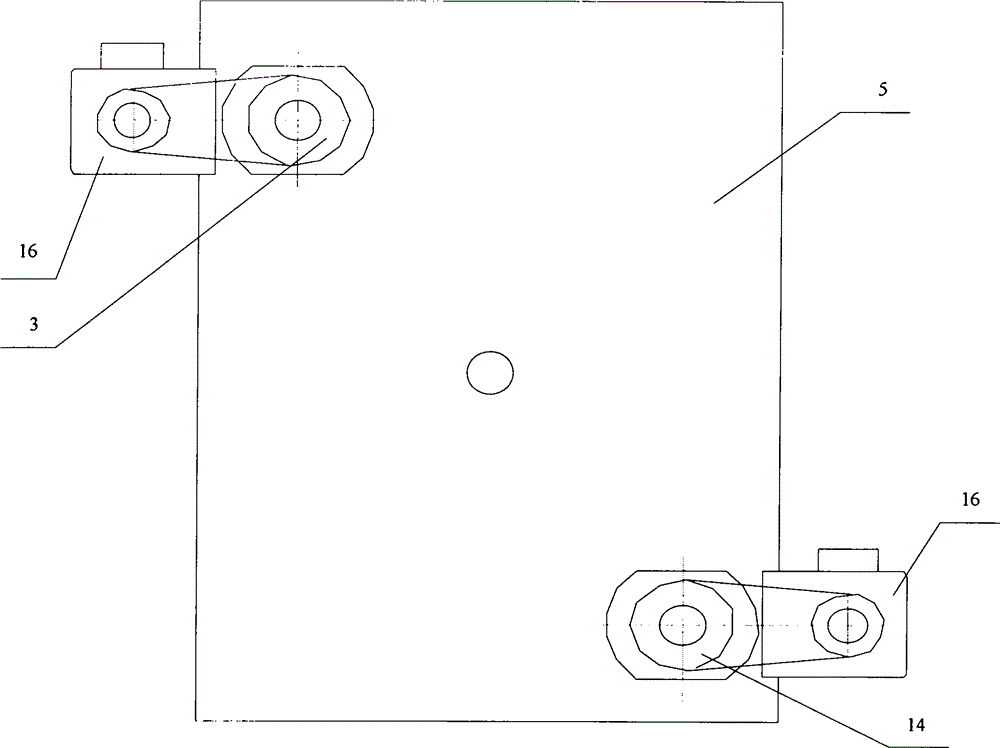

[0027] The present invention as figure 1 As shown, it includes a bed 11, a rotary wheel mechanism, a support device 7, a longitudinal feed mechanism and a fixed short mandrel 12. The rotary wheel mechanism includes a rotary wheel 9 and a rotary wheel lateral feed mechanism 10, and the rotary wheel 9 passes through the rotary wheel. The feed mechanism 10 is fixed on the bed 11, the longitudinal position is fixed, the fixed short mandrel 12 penetrates into the spinning blank 8, and is longitudinally fixed at the position of the rotary wheel 6 through the mandrel tie rod 4, and the short mandrel 12 and the rotary wheel 9 are fixed The longitudinal position does not change during the spinning process.

[0028] The bed 11 is arranged and connected with various mechanical components and guide rails to withstand various forces and realize functions. The headstock and other components move on the guide rails. On the other hand, the bed is connected to the foundation through anchor scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com