A Hobbing Cutter Holder for Small Modulus NC Gear Hobbing Machine

A technology of gear hobbing machine and gear hobbing cutter, which can be used in gear cutting machines, components with teeth, gear teeth manufacturing devices, etc., and can solve problems such as unfavorable spindle rotation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

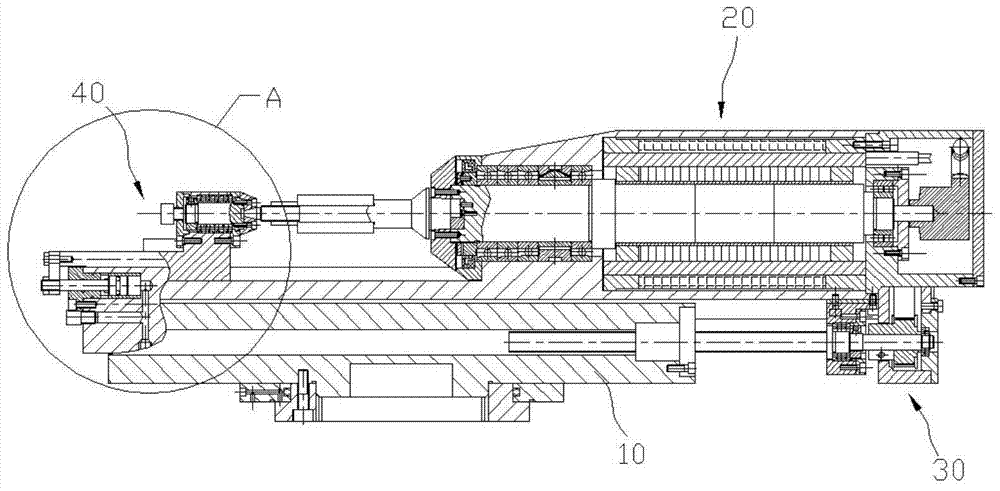

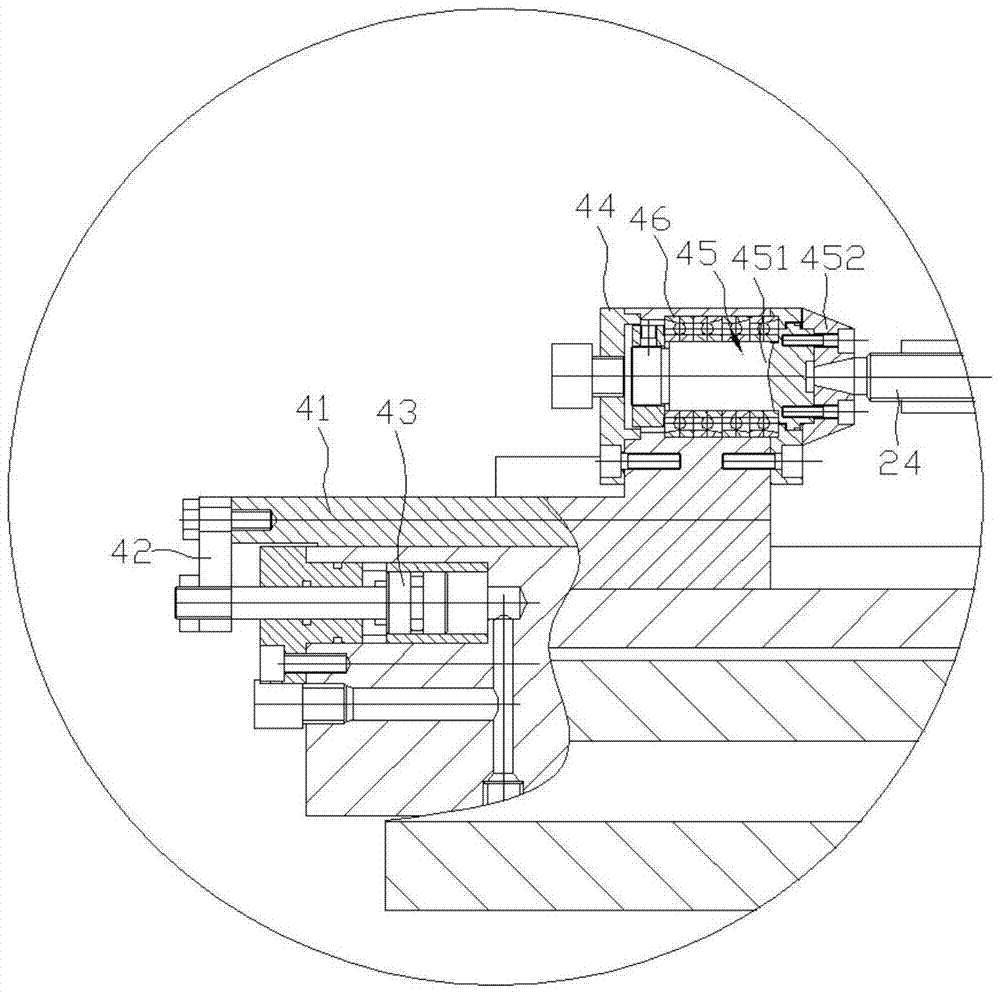

[0031] Such as figure 1 , a hobbing tool holder for a small-module numerically controlled gear hobbing machine, comprising a tool holder body part 10 , a tool holder main shaft part 20 , a tool holder shifting part 30 , and a tool holder tailstock part 40 .

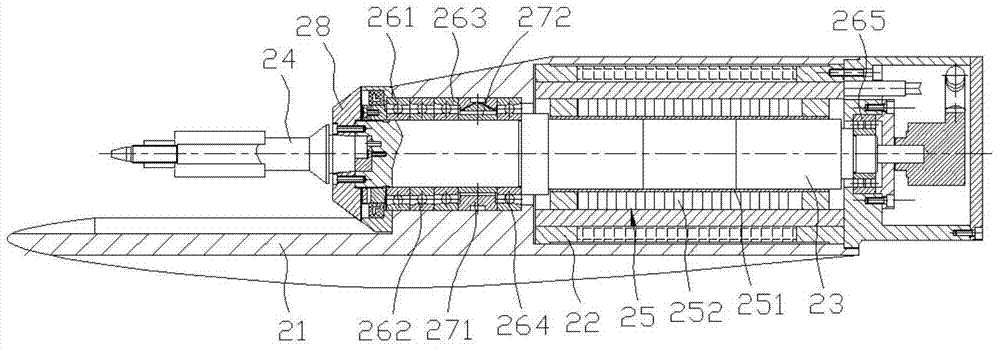

[0032] Such as figure 2 , the tool rest main shaft part 20 comprises a tool rest slide plate 21, a spindle box 22 installed on the tool rest slide plate, a main shaft 23 pivotally connected in the spindle box, and a knife bar 24; On the top plane, the slide plate of the tool holder can move horizontally and straightly along the top plane of the tool holder body;

[0033] In the above-mentioned tool post spindle part 20, such as figure 2 , the spindle box 22 is provided with a torque motor 25, the rotor 251 of the torque motor is fixed on the main shaft, and the stator 252 of the torque motor is installed on the inner wall of the spindle box.

[0034] In the above-mentioned tool post spindle part 20, such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com