Method and device for controlling groove of workpiece cut by robot

A technology of robots and workpieces, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve time-consuming, labor-intensive and precision problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

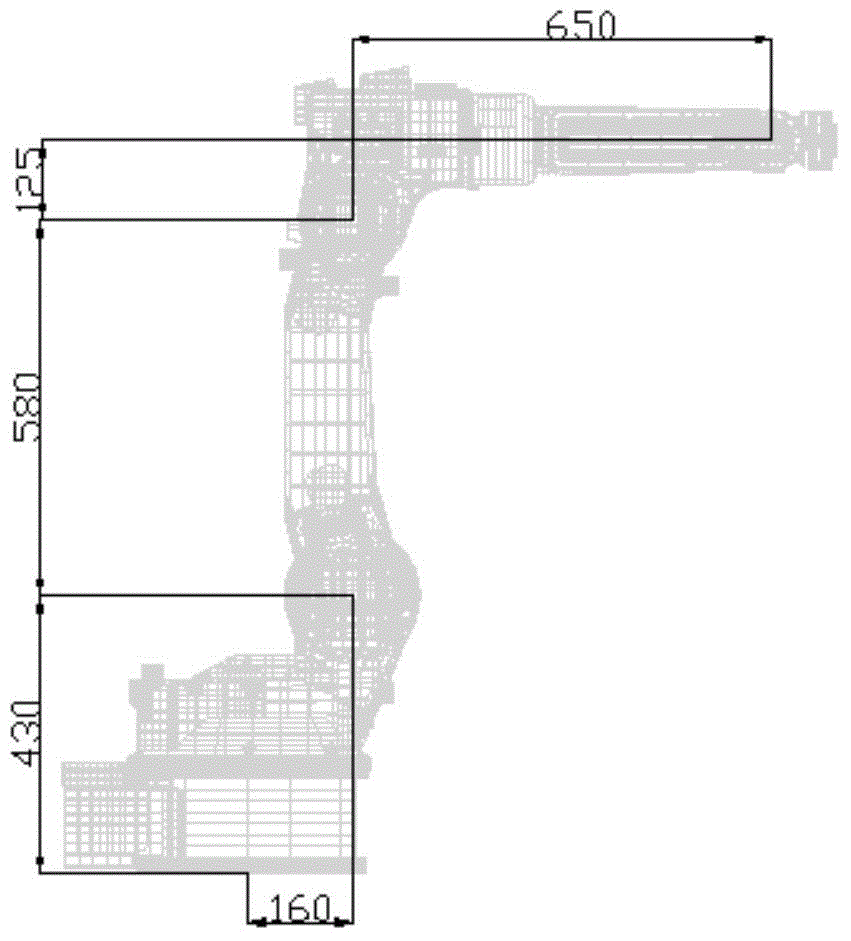

[0051] First, combined with the Figures 1 to 8 The method described in the embodiment of the present invention is described in detail.

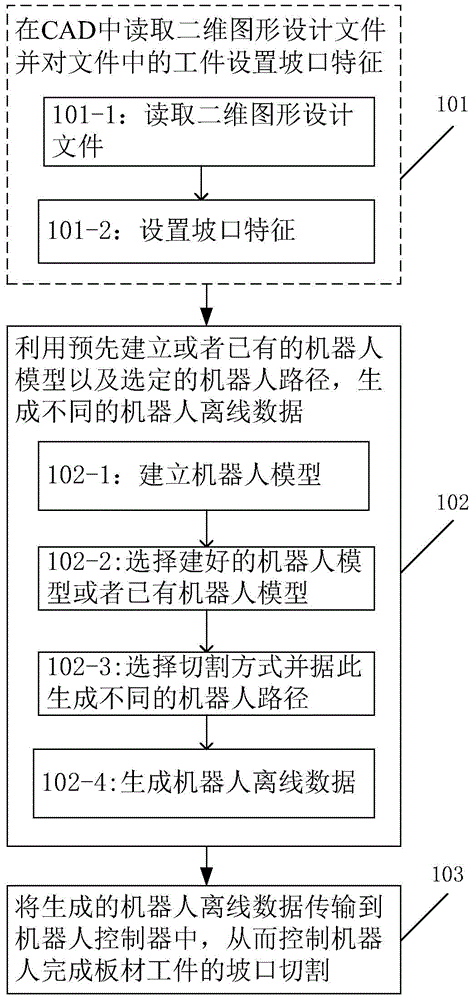

[0052] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the method described in the embodiment of the present invention, which may specifically include:

[0053] Step 101: Read the dwg format file of the CAD graphics of the plate workpiece, select the bevel cutting edge and set the groove height and angle parameters, and complete the setting of the bevel feature of the plate workpiece.

[0054] The above step 101 may specifically include:

[0055] Step 101-1: In CAD, open the existing two-dimensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com