A device for degassing and removing slag from molten aluminum

A technology of aluminum liquid and liquid storage tank, which is applied in the field of impurity devices, can solve problems such as insecurity, and achieve the effect of reducing the probability of safety accidents and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

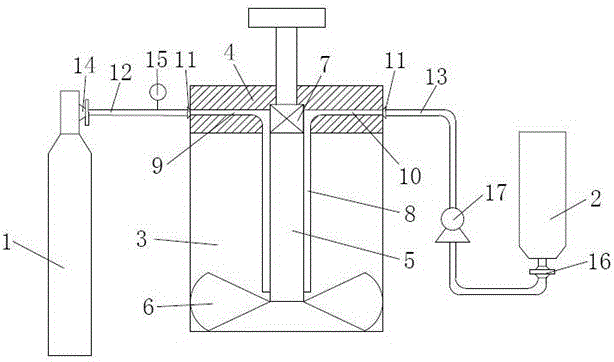

[0018] Example: see figure 1 Shown:

[0019] A liquid aluminum degassing and slag removal device, comprising a gas storage bottle 1, a liquid storage tank 2, and a holding furnace 3; a slag removal agent is sealed in the liquid storage tank 2; a cover plate 4 is covered on the top of the holding furnace 3 The center of the cover plate 4 is provided with a hydraulic telescopic rod 5; the bottom of the hydraulic telescopic rod 5 is provided with a rotatable fan-shaped stirring blade 6; the center of the cover plate 4 is provided with a drive for driving the stirring blade 6 to rotate and stir The motor 7; the outside of the hydraulic telescopic rod 5 is also covered with a gas-liquid mixing tube 8; the cover plate 4 is provided with an air flow channel 9 that can pass through the gas and a liquid channel 10 that can pass through the liquid; the air flow channel 9 and the liquid The channel 10 is connected to the gap between the gas-liquid mixing pipe 8 and the hydraulic telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com