Decelerating clutch of washing machine and washing machine

A deceleration clutch and washing machine technology, applied in the field of washing machines, can solve problems such as poor overrunning clutch, large vibration of washing machines, failure of one-way bearings, etc., and achieve the effects of novel structure, improved cleaning ratio, and improved carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

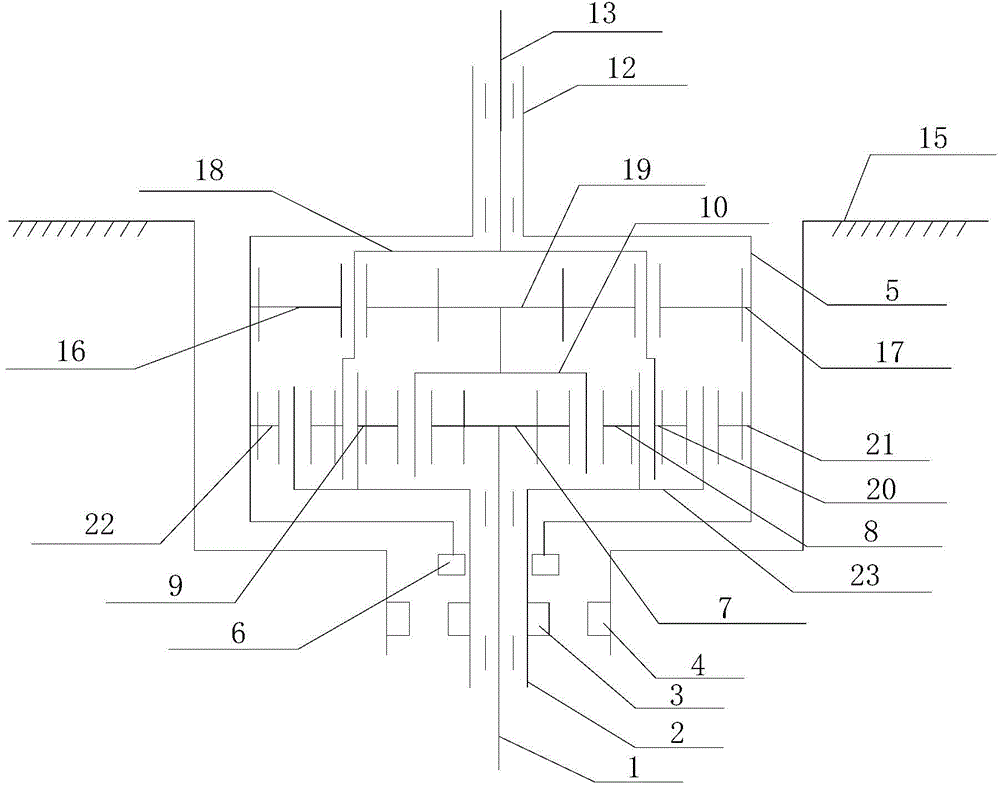

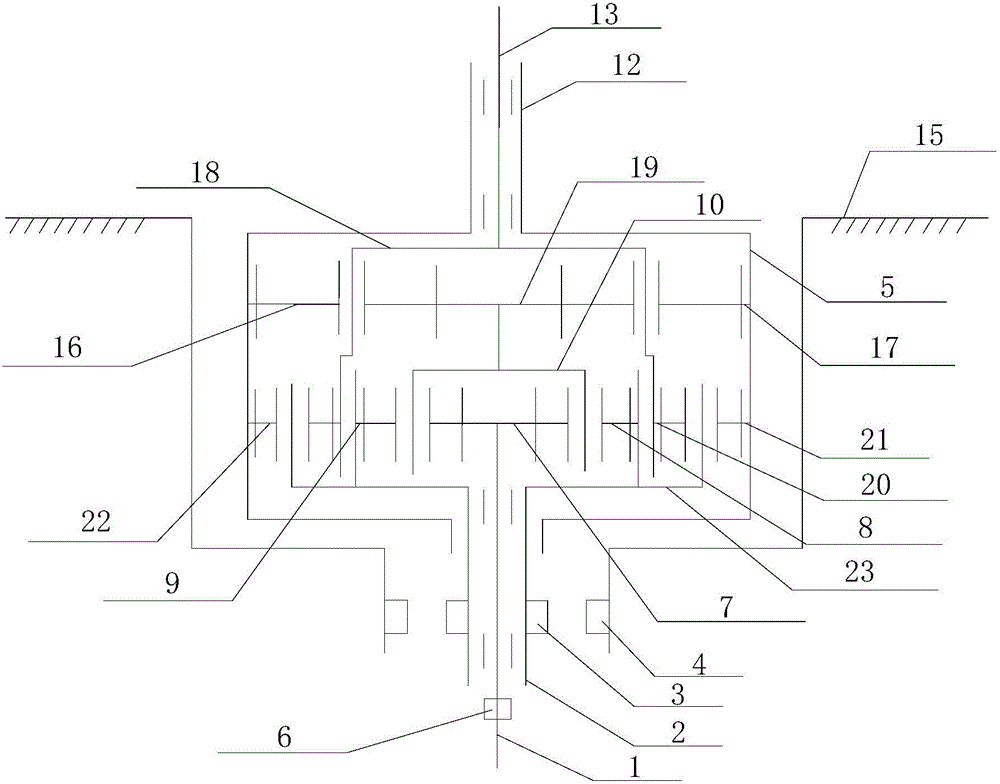

[0038] Such as figure 1 and figure 2 As shown, in the deceleration clutch of the washing machine described in this embodiment, the first gear train is a planetary gear train, mainly composed of the first sun gear 7, the first planetary gear 8, the first internal gear 9, the first planetary gear frame 10, the first sun gear 7 is installed on the input shaft 1, the first internal gear 9 is arranged in the cavity of the brake wheel 5, the first planetary gears 8 are evenly distributed on the same circumference of the first planetary wheel frame 10, and the first The planetary gear 8 meshes with the first sun gear 7 and the first internal gear 9 at the same time, the first internal gear 9 is connected with the input shaft sleeve 2 as a whole, and the first planetary gear carrier 10 is in transmission connection with the second gear train.

[0039] The second gear train is mainly composed of the second central gear 19, the second internal gear 17, the second planetary gear 16, an...

Embodiment 2

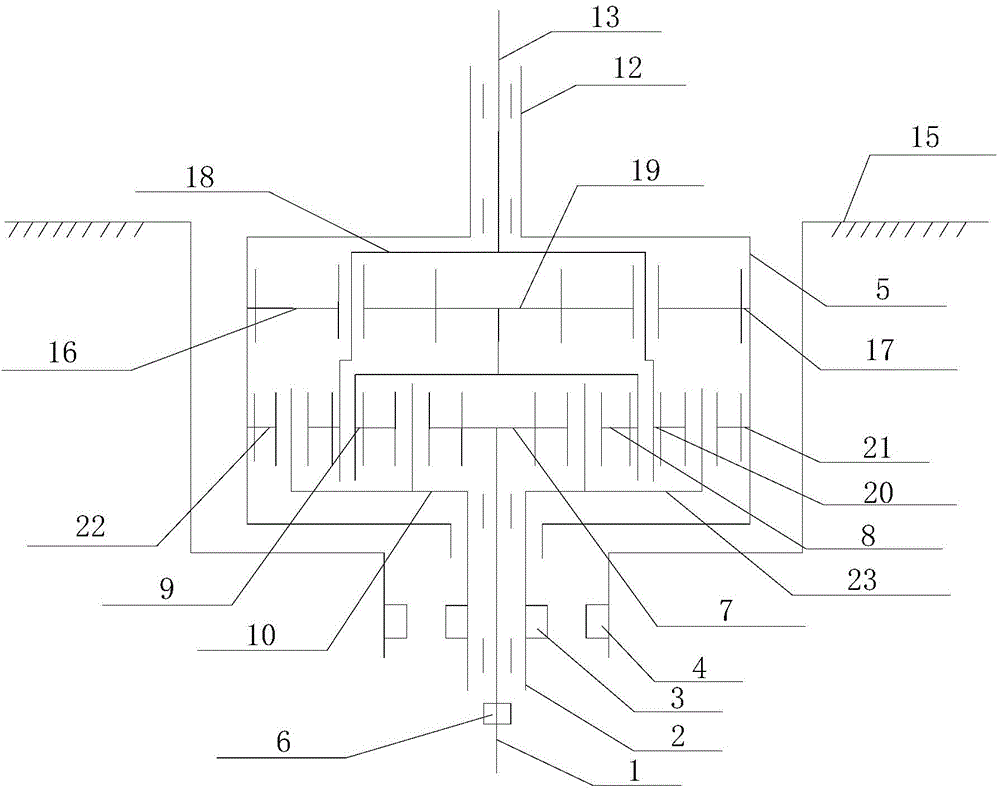

[0043] Such as image 3 As shown, the difference between this embodiment and the first embodiment lies in that the transmission connection relationship between the first gear train and the second gear train and the connection relationship between the first gear train and the input shaft sleeve 2 are different.

[0044] The first gear train is mainly composed of the first sun gear 7, the first planetary gear 8, the first internal gear 9, and the first planetary carrier 10. The first sun gear 7 is installed on the input shaft 1, and the first internal gear 9 is set In the chamber of the brake wheel 5, the first planetary gears 8 are evenly distributed on the same circumference of the first planetary gear carrier 10, and mesh with the first sun gear 7 and the first internal gear 9 at the same time, the first planetary gear carrier 10 and the input shaft The sleeve 2 is connected as a whole, and the first internal gear 9 is connected with the second wheel train in transmission.

...

Embodiment 3

[0047] Such as figure 1 As shown, the clutch device described in this embodiment includes a dehydration pin 6 installed on the lower end of the brake wheel 5, a clutch sleeve 3 installed on the input shaft sleeve 2 and rotating integrally with the input shaft sleeve, and a braking pin installed on the lower end of the housing 15. Pin 4 and driving clutch sleeve 3 are respectively connected to / disconnected with dehydration pin 6 and brake pin 4;

[0048] In the washing state, the drive unit controls the clutch sleeve 3 to be connected to the brake pin 4 and disconnected from the dehydration pin 6 . In the dehydration state, the drive unit controls the clutch sleeve 3 to be connected to the dehydration pin 6 and to be disconnected from the brake pin 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com