Building block type inspection well device

A technology of building block and manhole, which is applied in the field of building block manhole device, can solve the problems that people's lives cannot be well protected, the bearing capacity is poor, the manhole is easy to collapse, etc., so as to achieve fast and convenient daily maintenance, guarantee life safety, and facilitate promotion. applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

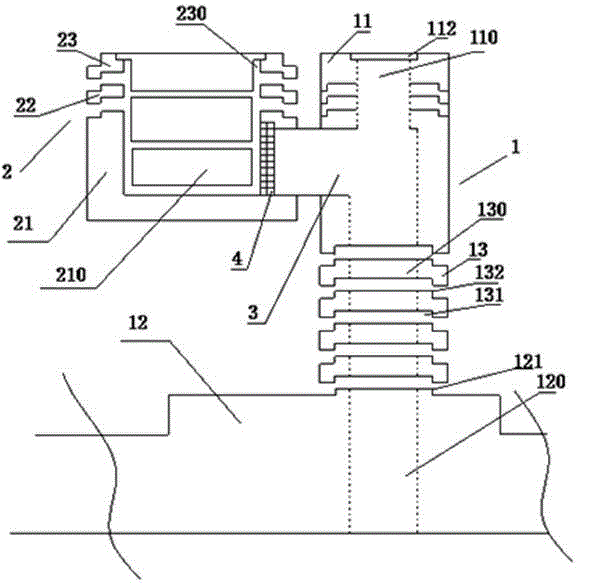

[0025] A building block type well inspection device, comprising a main inspection well 1 and a first branch inspection well 2, the main inspection well 1 and the first branch inspection well 2 are connected by a first pipeline 3;

[0026] The main inspection well 1 includes a first well cover body 11, a well tube body 12, and a plurality of stacked first inspection well rings 13. The well tube body 12 is provided with a first through hole 120, and the well tube body 12 is in the shape of a three-stage boss. Above the pipe body 12 is provided a plurality of stacked first silo ring 13, the first silo ring 13 is provided with a second through hole 130, the second through hole 130 and the first through hole 120 have the same inner diameter and pass through each other. The first manhole ring at the bottom is adapted to each other with the well tube body 12, two adjacent first manhole rings 13 are adapted to each other, and the first manhole cover body 11 is provided above the first man...

Embodiment 2

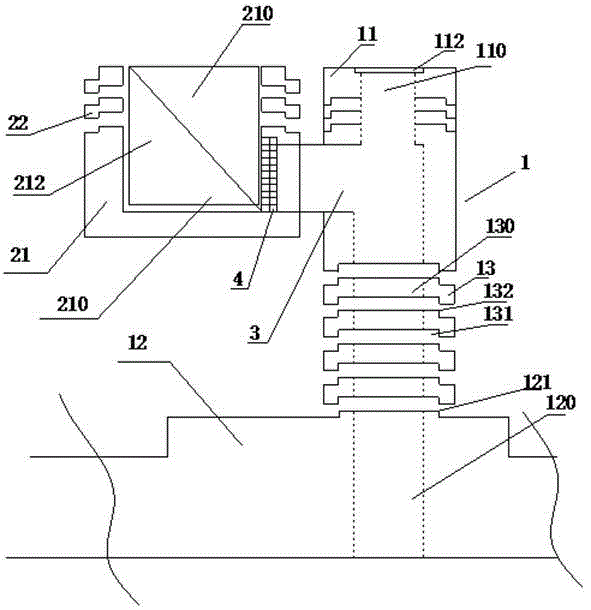

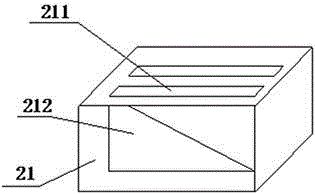

[0030] A building block type well inspection device, comprising a main inspection well 1 and a first branch inspection well 2, the main inspection well 1 and the first branch inspection well 2 are connected by a first pipeline 3;

[0031] The main inspection well 1 includes a first well cover body 11, a well tube body 12, and a plurality of stacked first inspection well rings 13. The well tube body 12 is provided with a first through hole 120, and the well tube body 12 is in the shape of a three-stage boss. Above the pipe body 12 is provided a plurality of stacked first silo ring 13, the first silo ring 13 is provided with a second through hole 130, the second through hole 130 and the first through hole 120 have the same inner diameter and pass through each other. The first manhole ring at the bottom is adapted to each other with the well tube body 12, two adjacent first manhole rings 13 are adapted to each other, and the first manhole cover body 11 is provided above the first man...

Embodiment 3

[0035] Reference Figure 5 , A building block type well device, comprising a main well 1, a first branch well 2, a second branch well 5 and a communication line 6, wherein the structure of the main well 1 and the first branch well 2 and the mutual connection and implementation of the two Example 1 is consistent.

[0036] The second branch well 5 includes an external well 51, an internal well 52, and a cement pier 53. The external well 51 includes a second frame 511 and at least one third well circle 512, the third well circle 512 placed in the second frame 511 Above, the third scoring ring 512 has the same structure as the first scoring ring 13. The second frame 511 is provided with a solid column 513 whose height is greater than the depth of the second frame 511; The inner manhole 52 is connected, and the depth of the inner manhole 52 is smaller than the depth of the second frame body 511. The inner manhole 52 is connected to the main manhole 1 through a second pipe 54. A cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com