Anti-backflow hydraulic automatic gate

An automatic gate and hydraulic automatic technology, applied in waterway systems, water conservancy projects, water supply devices, etc., can solve problems such as polluting the environment, consuming a lot of energy, and inconvenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

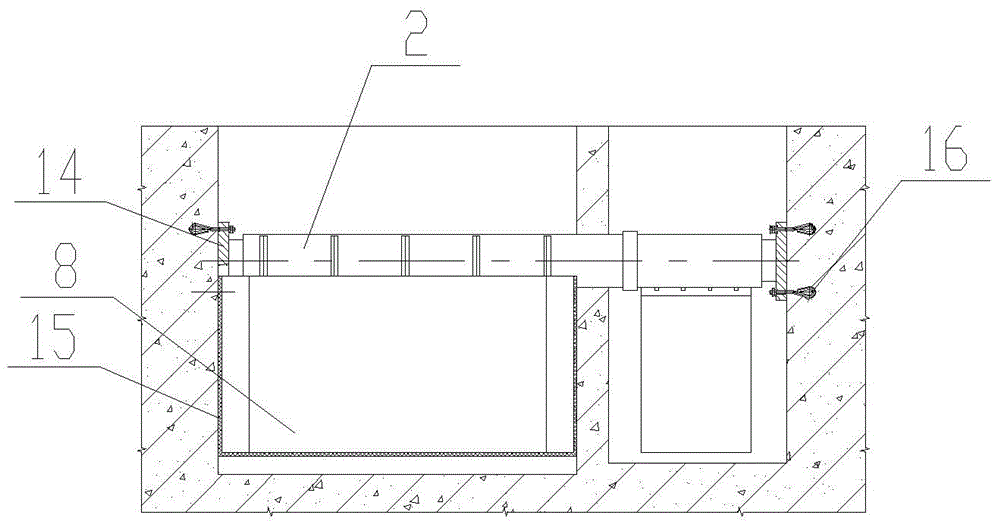

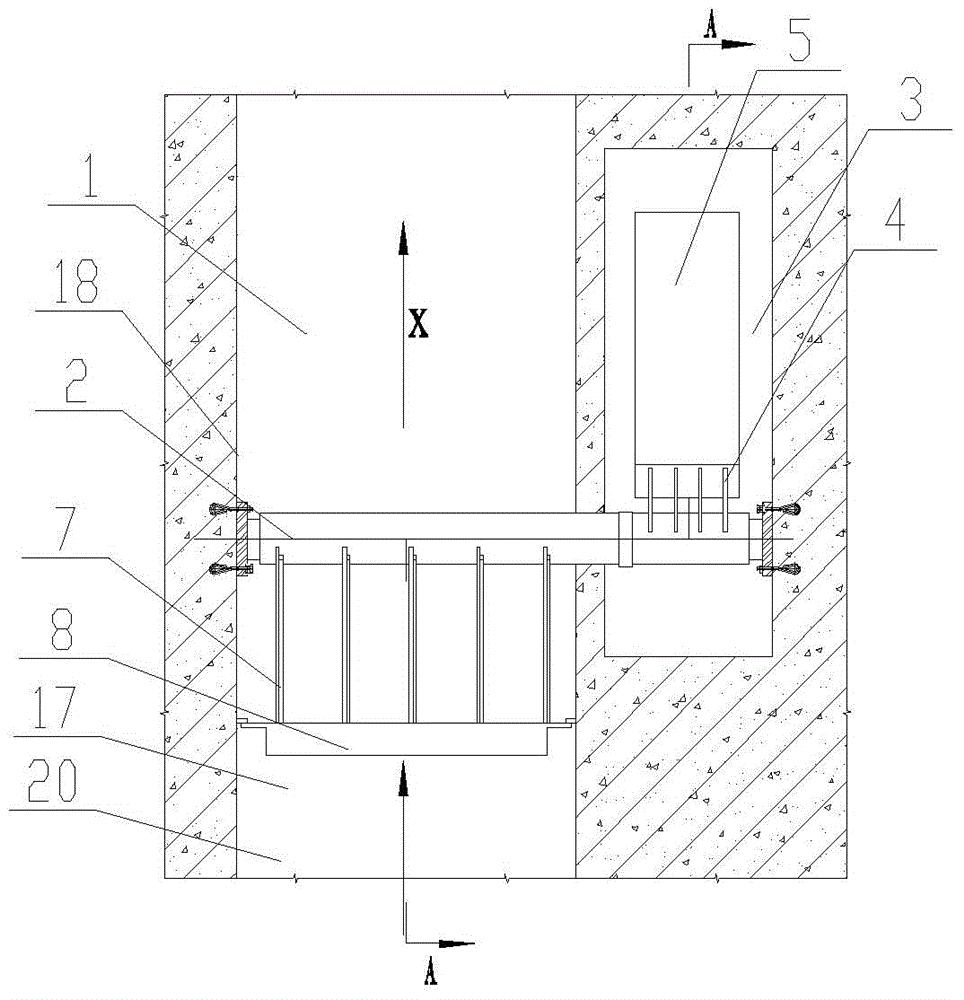

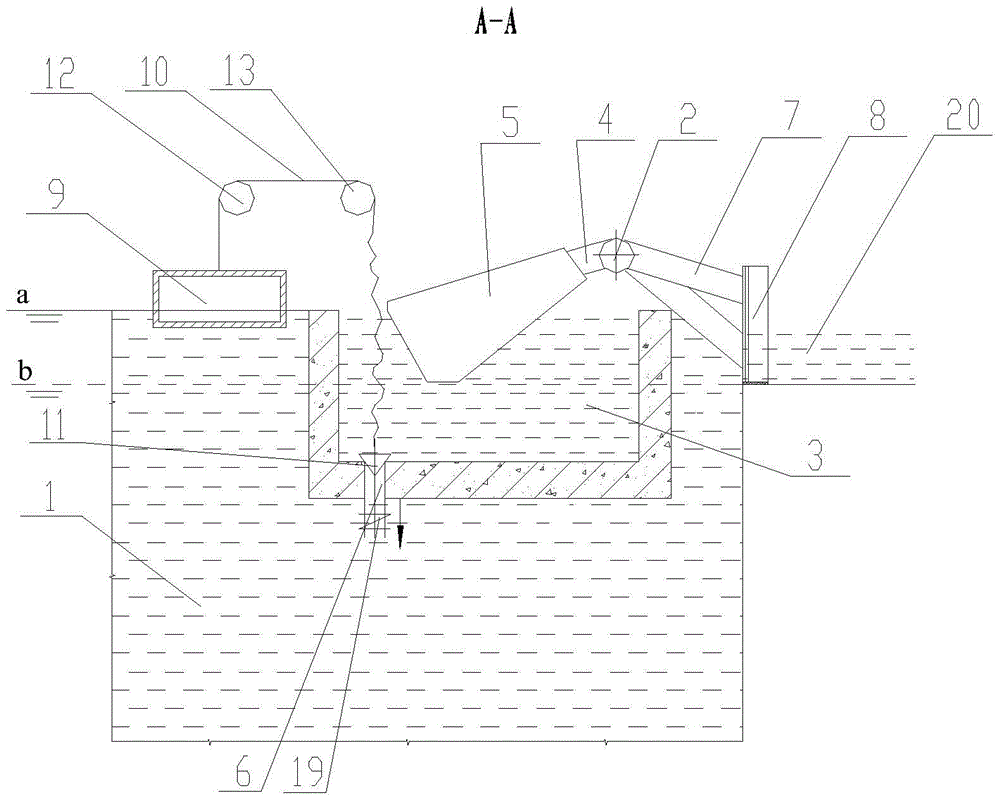

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0023] like Figure 1-Figure 3 As shown, the present invention includes a buffer tank 20 and an underground storage tank 1 arranged in the flow channel 17, the underground storage tank 1 is arranged lower than the buffer tank 20, and a gate 8 is arranged between the buffer tank 20 and the underground storage tank 1 , the two side edges and the bottom edge of the gate 8 are respectively sealed with the flow channel wall 18 on both sides and the bottom of the flow channel 17, and a sealing ring 15 is arranged between the two side edges and the bottom edge of the gate 8 and the flow channel wall 18 respectively, The gate 8 is fixed on one side of the rotating shaft 2, and the two ends of the rotating shaft 2 are respectively hinged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com