Drill

A drill bit and drill body technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of drill bit breakage and the inability of the drill bit to drill holes with different diameters, so as to increase drilling strength, save time, and reduce accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

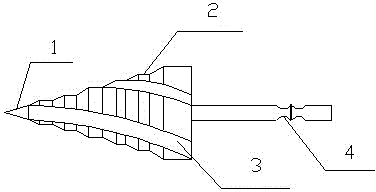

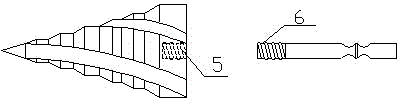

[0018] Reference numerals: 1, drill point, 2, drill body, 3, chip removal groove, 4, drill shank with groove, 5, internal thread on the inner surface of the drill, 6, external thread on the outer surface of the drill shank

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, a drill bit is composed of a drill shank 4 with a groove, a drill body 2 and a drill tip 1. The drill tip 1 is located at one end of the drill body 2 and is integrally structured with the drill body 2. The drill body 2 The other end is connected with the grooved drill shank 4 through a threaded structure. The structure of the drill body 2 is a stepped cone structure, and the diameters from the bottom end to the tip gradually decrease, so that holes with different diameters can be dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com