Method for setting up end-mining and withdrawal roadway for fully mechanized coal mining face with large mining height

A technology of fully mechanized working face and large mining height, applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of low coal recovery rate, strong coal wall slug, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

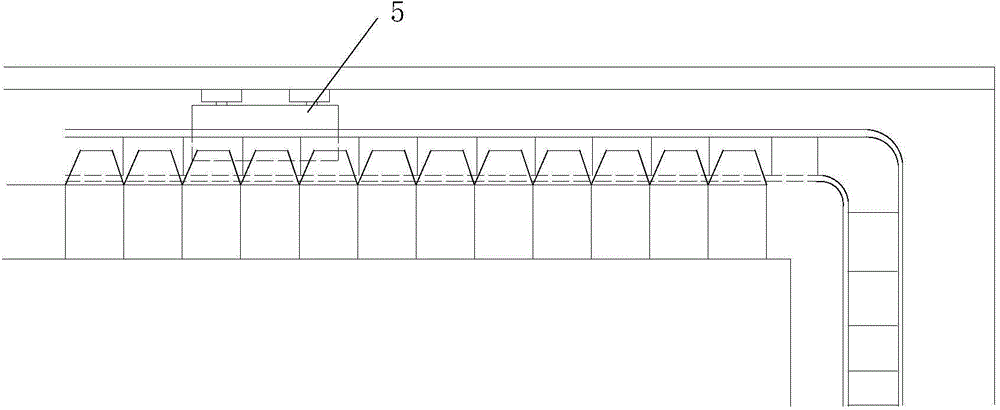

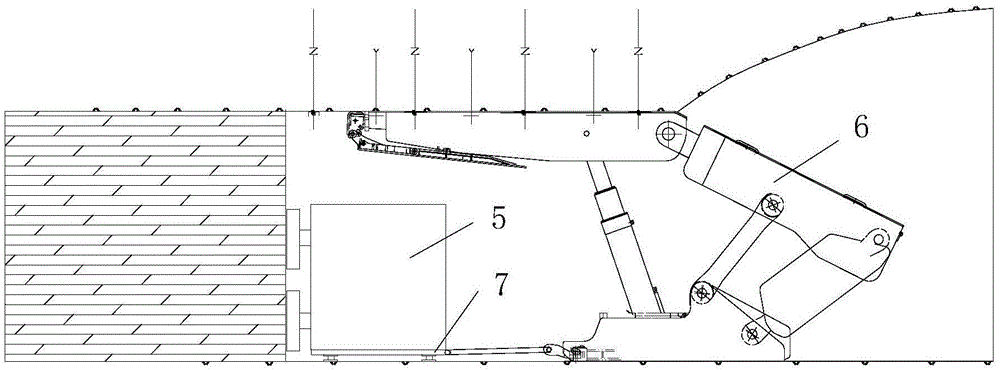

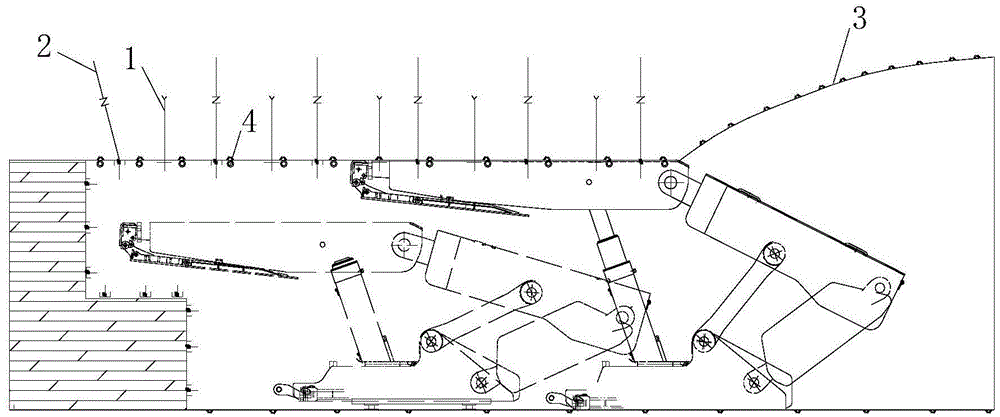

[0013] combine figure 1 , figure 2 , image 3 As shown in the figure, a method for leaving a retraction roadway at the end of a fully mechanized mining face with a large mining height, including a bolt 1, an anchor cable 2, a metal mesh 3, a steel wire rope 4, a shearer 5, a hydraulic support 6, and a scraper conveyor 7. The anchor rod 1 and the anchor cable 2 are staggered and anchored at the roof of the fully mechanized mining face and the coal wall of the retracted roadway, the steel wire rope 4 is placed under the metal mesh 3, and the steel wire rope 4 and the metal mesh 3 are connected The lower ends of the anchor rod 1 and the anchor cable 2 are fixed and placed on the roof and the surface of the coal wall, the scraper conveyor 7 is placed on the fully mechanized mining face, and the shearer 5 is placed on the upper part of the scraper conveyor 7, The bottom of the hydraulic support 6 is connected to the side of the scraper conveyor 7 away from the coal wall.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com