Method for predicting gas emission quantity of working face under pressure relief condition

A gas gushing volume and gas gushing technology, which is applied in the field of gas gushing volume prediction of working face based on pressure relief conditions, can solve the problems of inaccurate gas gushing volume prediction and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for predicting the amount of gas gushing out of a working face based on the pressure relief condition of this embodiment includes the following steps:

[0031] a. Determine the source composition of the gas emission in the mining face. The source of the gas emission in the mining face includes the gas emission from the coal wall, the gas emission from the mined coal, the gas emission from the coal left in the goaf or / and the gas emission from adjacent layers.

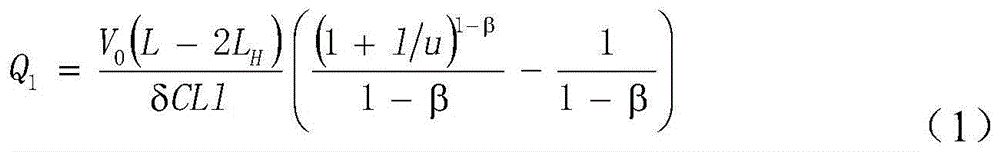

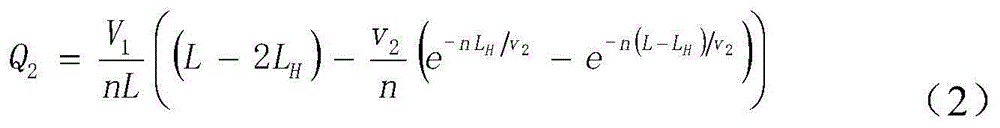

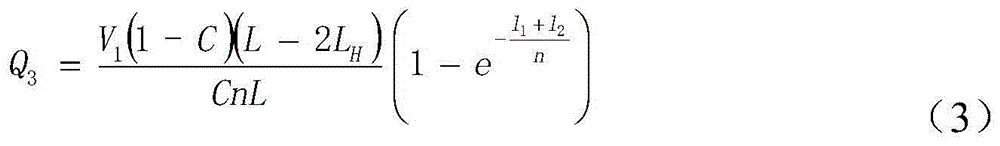

[0032] b. Calculate the amount of gas emission from each gas emission source separately. The amount of gas emission in the mining face mainly depends on the intensity of gas emission from the gas source. Usually, it is calculated by the amount of gas emitted per square meter of coal wall per unit time. Indicates the gas gushing intensity of the coal wall, and the gas gushing intensity of falling coal is expressed by the amount of gas gushing per ton of coal per unit time. in,

[0033] The formula for ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com