Valve for controlling piston cooling nozzles in internal combustion engines

A technology for piston cooling nozzles and internal combustion engines, which is used in engine cooling, lubricant pressure control, liquid cooling, etc., can solve problems such as ECU calculation load, increase engine system cost, and engine system wiring complexity, and simplify operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments will be described with reference to the accompanying drawings.

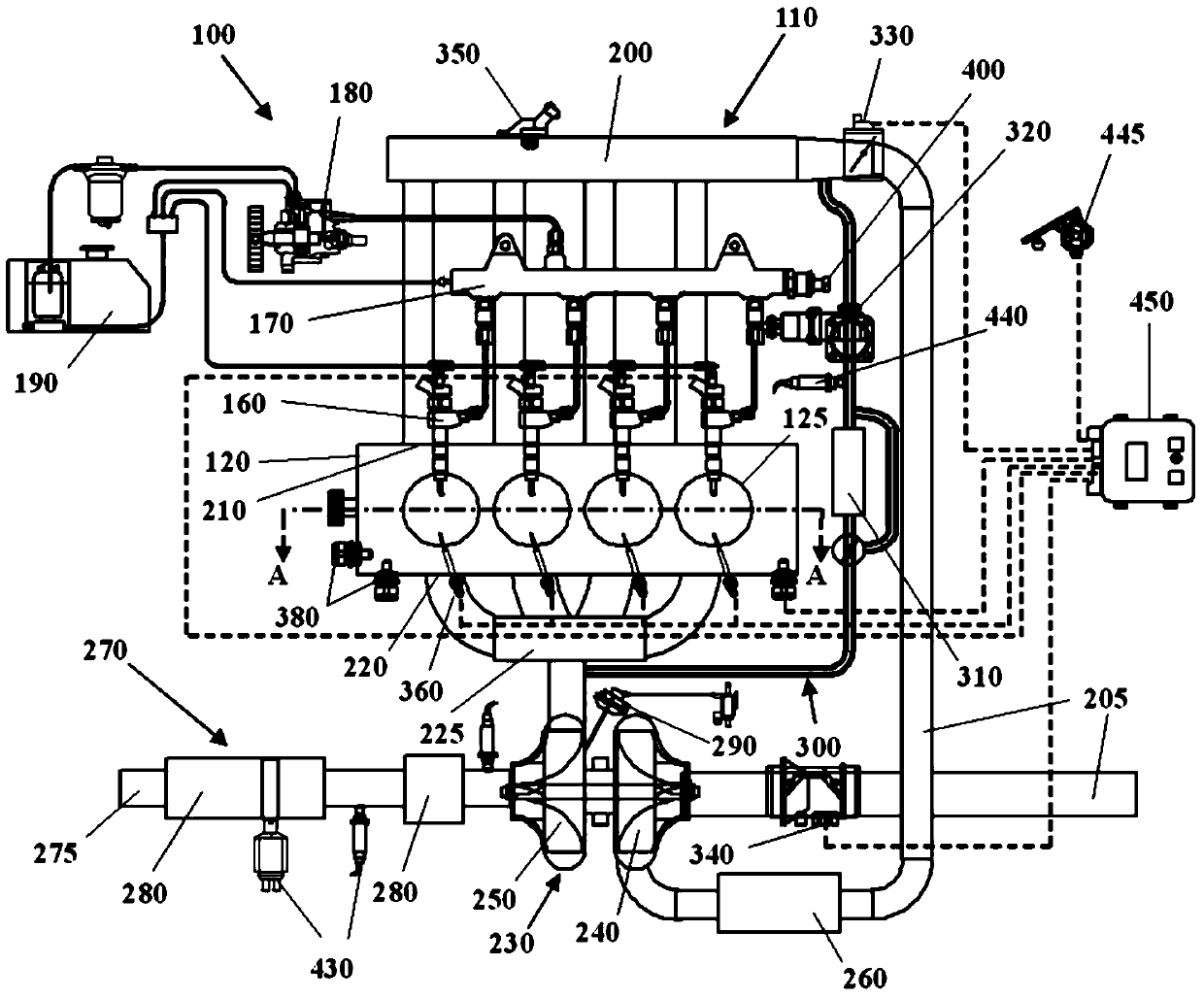

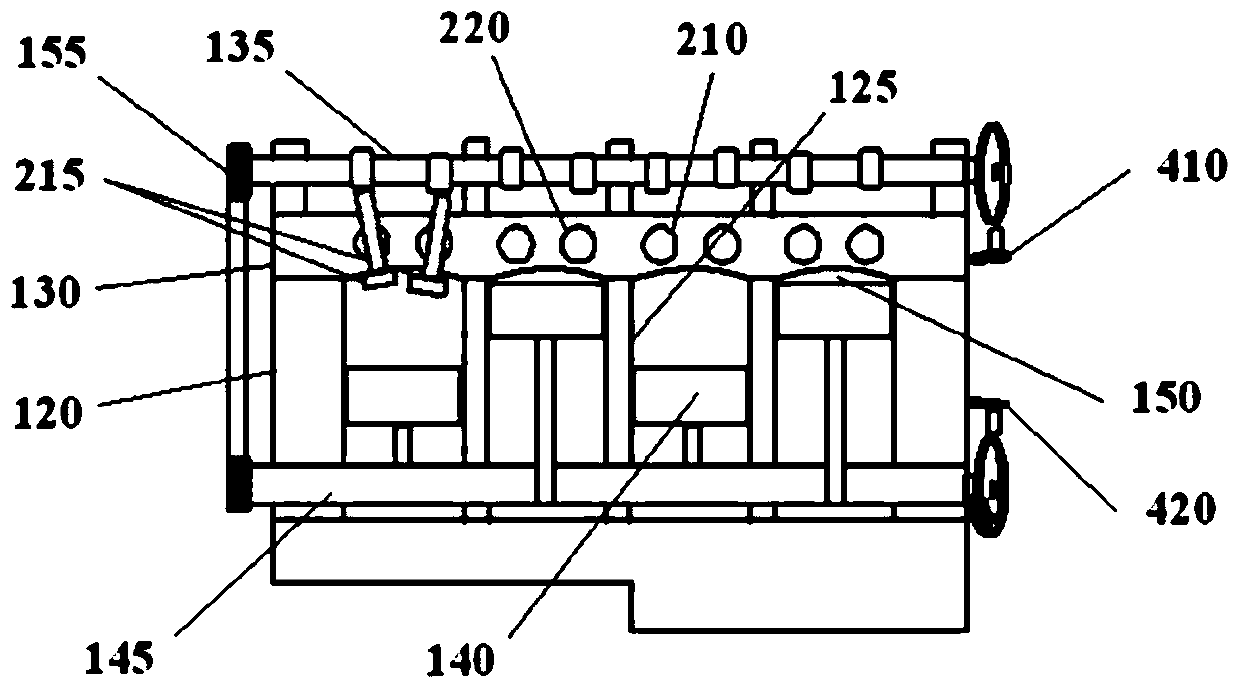

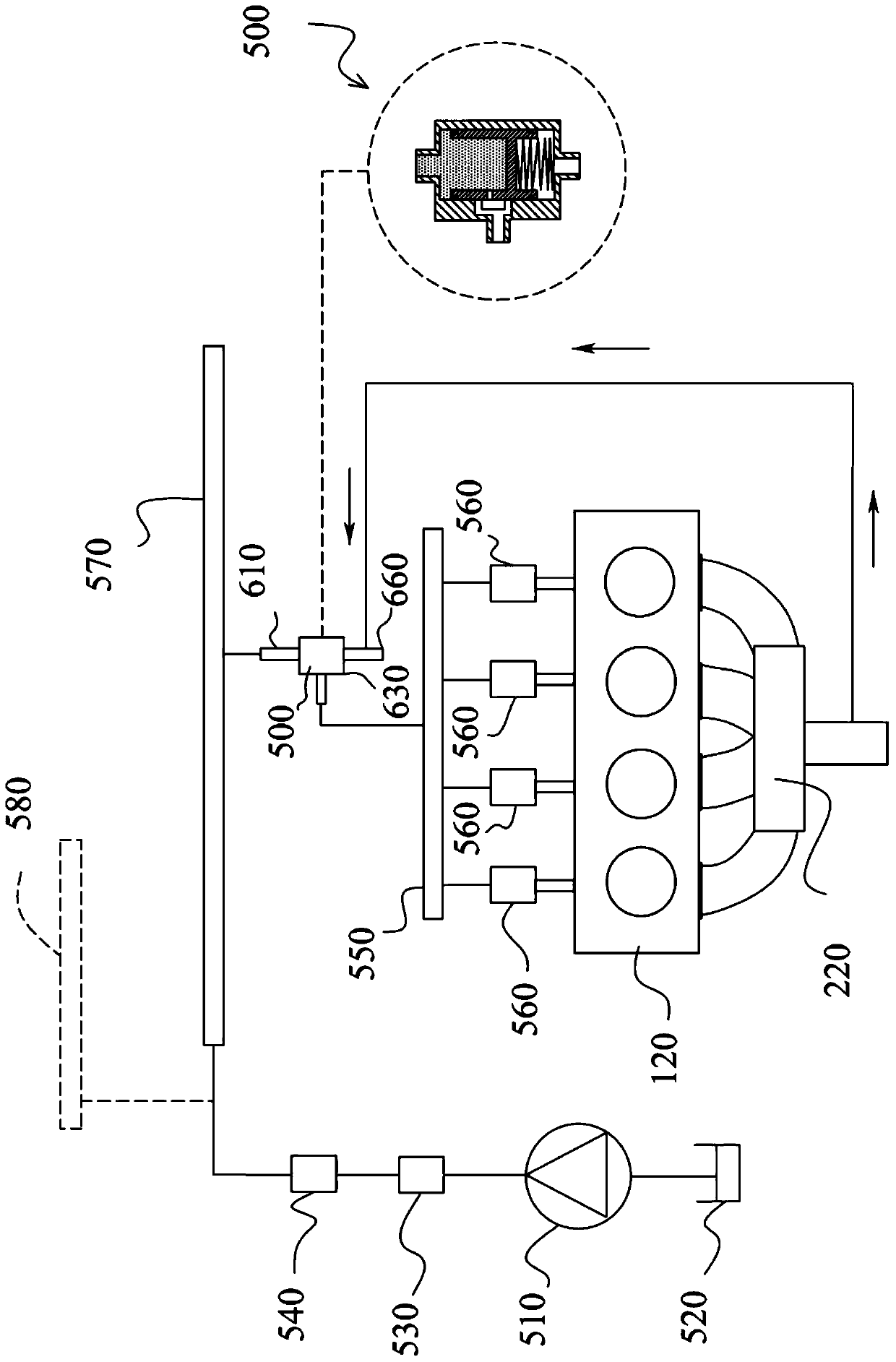

[0039] Some embodiments can include automotive systems 100 such as figure 1 and figure 2 As shown, it includes an internal combustion engine (ICE) 110 having an engine block 120 defining at least one cylinder 125 having a piston 140 coupled to rotate a crankshaft 145 disposed in a crankcore. Cylinder head 130 cooperates with piston 140 to define combustion chamber 150 . A fuel and air mixture (not shown) is placed in combustion chamber 150 and ignited, resulting in thermally expanding exhaust gases to cause reciprocating motion of piston 140 . Fuel is provided by at least one fuel injector 160 and air is drawn through at least one air intake 210 . Fuel is provided to fuel injector 160 at high pressure from fuel rail 170 in fluid communication with high pressure fuel pump 180 which increases the pressure of fuel from fuel source 190 . Each cylinder 125 has at least two valves 215 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com