Dish washing machine, and speed adjustment control method and system for alternating current washing electric pump of dish washing machine

A control method and technology for a control system, which are applied in the field of speed regulation control of a dishwasher and its AC washing electric pump, can solve the problems of reducing noise and energy consumption of an unwashable electric pump, and achieve the reduction of noise and energy consumption. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

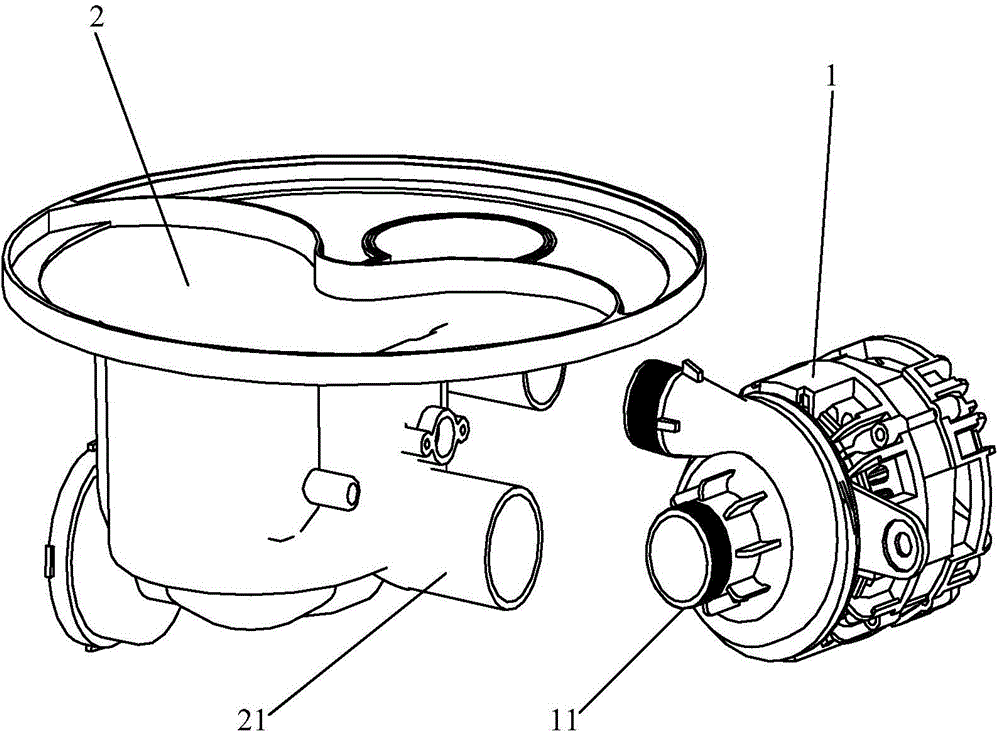

[0035] In this example, if figure 1 As shown, the pump body 1 of the AC washing electric pump is connected with the water cup 2 in the dishwasher. Specifically, the water inlet 11 of the pump body 1 is connected to the cylindrical flow channel 21 of the water cup 2, and the pump body 1 obtains water supply directly from the water cup 2, thereby reducing water flow loss and pressure loss without connecting pipes.

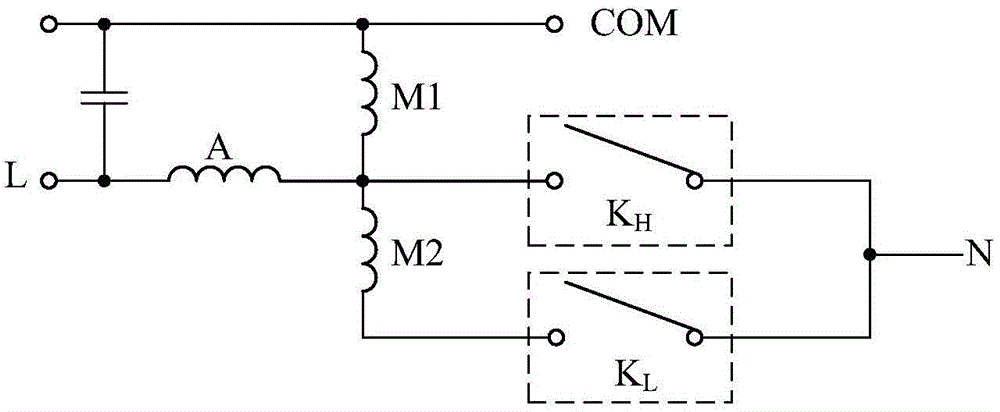

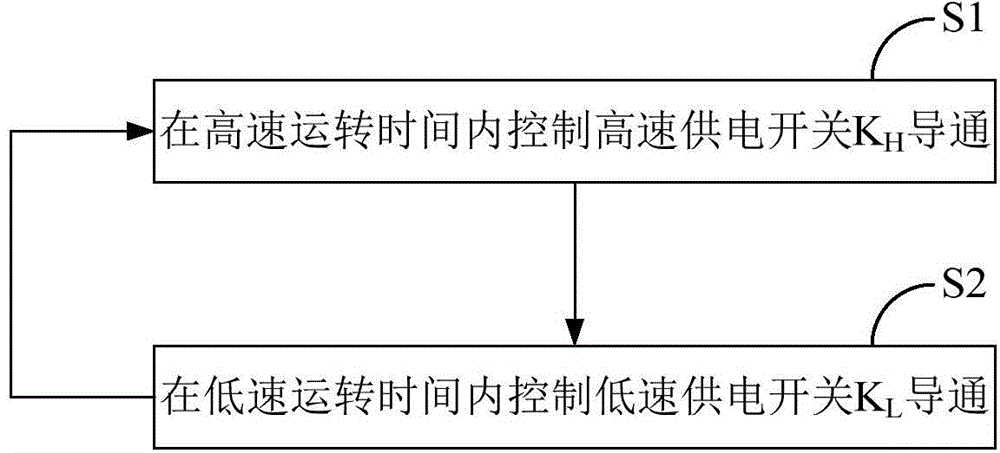

[0036] Such as figure 2 As shown, the stator winding of the motor in the AC washing electric pump includes the first main phase winding M1, the second main phase winding M2 and the auxiliary phase winding A, the first end of the first main phase winding M1 is connected to the second main phase winding M2 The first end of A and the first end of the auxiliary phase winding A are connected to the high-speed power supply switch K in the dishwasher H, the second end of the first main phase winding M1 is connected to the ground wire COM, and the second end of the second...

Embodiment 2

[0052] In this embodiment, with Embodiment 1 figure 1 As shown, the pump body 1 of the AC washing electric pump is connected with the water cup 2 in the dishwasher. Specifically, the water inlet 11 of the pump body 1 is connected to the cylindrical flow channel 21 of the water cup 2, and the pump body 1 obtains water supply directly from the water cup 2, thereby reducing water flow loss and pressure loss without connecting pipes.

[0053] Such as Figure 5 As shown, the stator winding of the motor in the AC washing electric pump includes the first main phase winding M1, the second main phase winding M2, the third main phase winding M3 and the auxiliary phase winding A, the first end of the first main phase winding M1 The high-speed power supply switch K in the dishwasher is commonly connected with the first end of the second main phase winding M2 and the first end of the auxiliary phase winding A H , the second end of the first main phase winding M1 is connected to the groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com