A Shaft Type Tubular Flow Pump Apparatus for Model Test

A model test and model pump technology, which is applied to components of pumping devices for elastic fluids, pump devices, non-variable pumps, etc., can solve the problems affecting the stability of pump device performance test data and the difficulty in ensuring installation concentricity , Shafting operation instability and other problems, to achieve the effect of facilitating the comparison of hydraulic performance of the pump device, stable shafting operation, and stable test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0044] The purpose of the present invention is achieved like this:

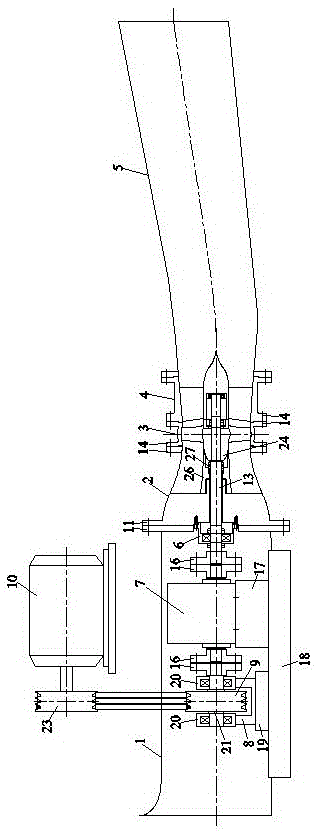

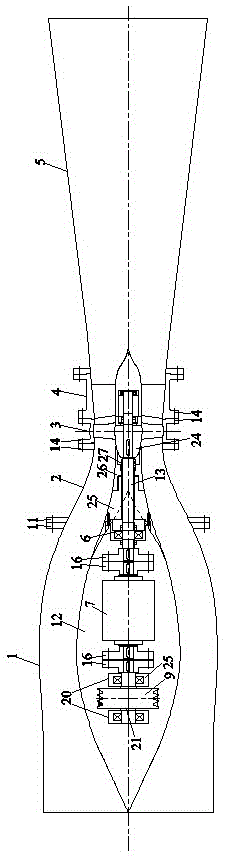

[0045] (1) The shaft type tubular pump device model used for the model test, which adopts a short-axis transmission system, which includes the shaft section 1 of the water inlet channel, the circular platform section 2 of the water inlet channel, the model pump impeller and impeller chamber 3, and the model pump guide vane Body 4, water outlet channel section 5, thrust bearing and bearing seat 6, torque meter 7, belt pulley seat 8, belt pulley 9, drive motor 10, etc., such as Figure 1a , Figure 1b shown;

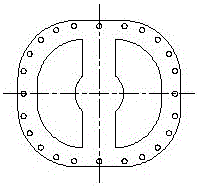

[0046] (2) Structurally divide the water inlet channel section into a shaft section 1 and a round table section 2. The two are connected by a straight-edge rounded flange 11. The outlet section of section 1 is welded, and the straight-edge rounded flange 11 on one side of the round tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com