Surface strength testing apparatus

A test device and surface strength technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, and can solve problems such as sharp edges of thin film specimens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

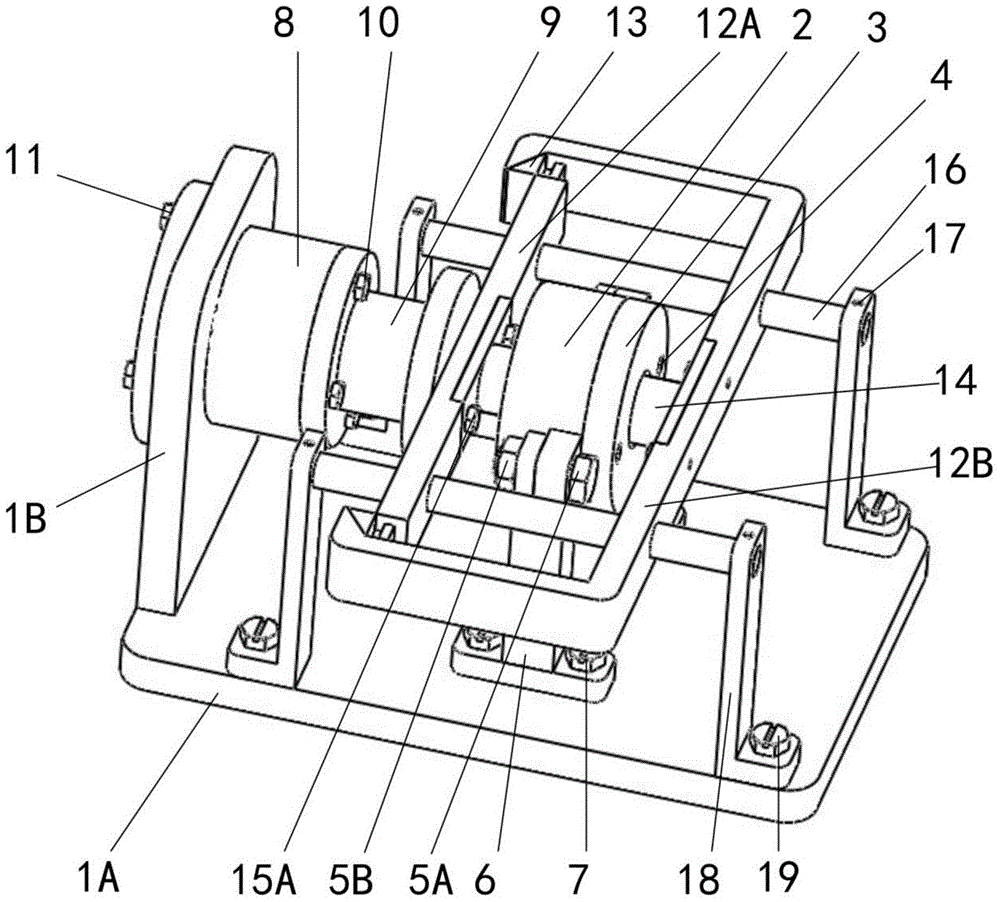

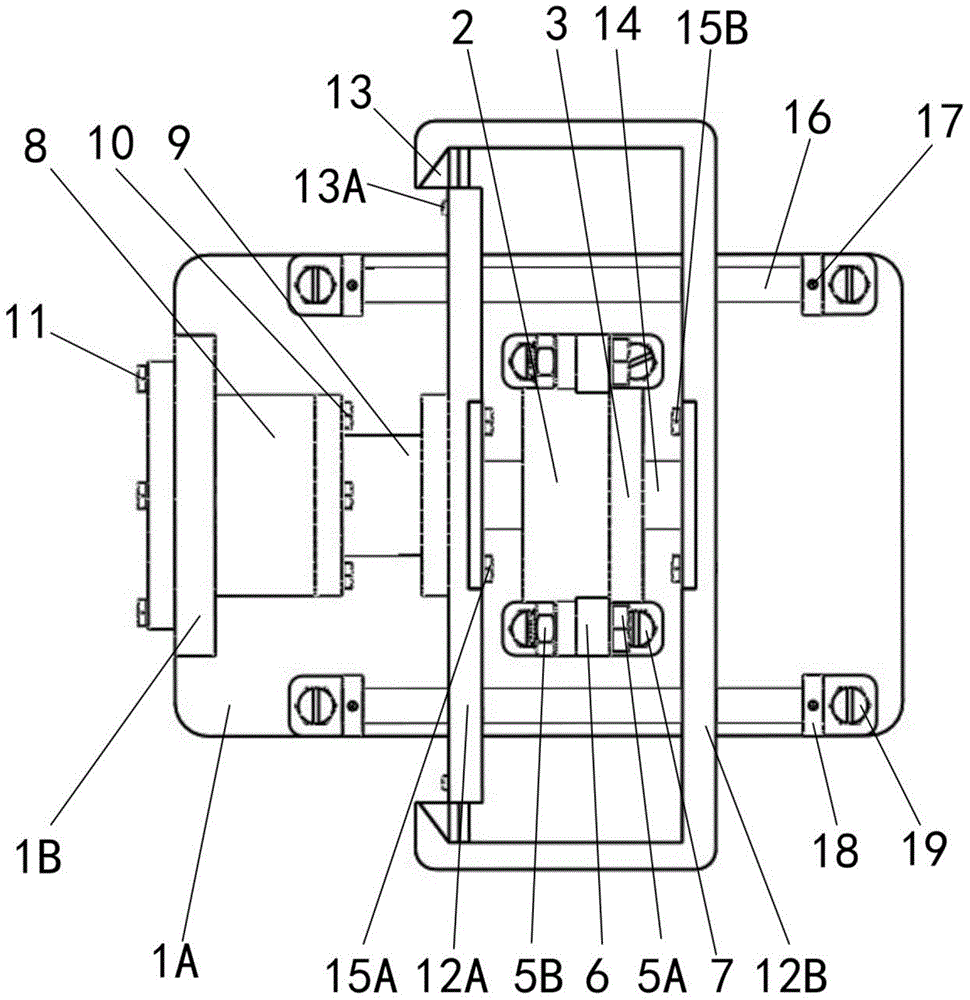

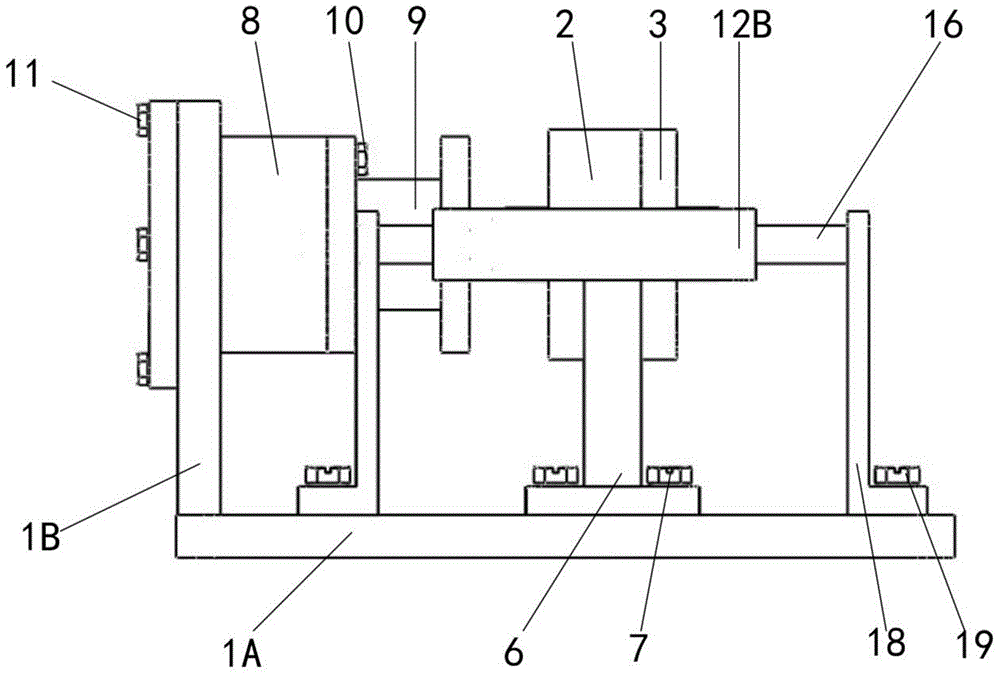

[0027] See figure 1 — Figure 7 , the specific embodiment of the present invention will be further described in conjunction with accompanying drawing:

[0028] The invention provides a surface strength testing device, which includes a machine base, a film fixing part, a stamping part and a stamping driving part. The position connection relationship among them is: the film fixed part, the stamping part and the stamping driving part are all fixedly connected on the machine base.

[0029] Step 1: Install the film fixing part. The fixed part of the film is composed of left clamp body 2, right clamp body 3, and film specimen 2,0. The left clamp body 2 is a cylinder as a whole, and the left clamp body 2 has a round hole on the central axis of the left end surface (the diameter of the round hole is larger than the diameter of the stamping head, smaller than the diameter of the film test piece), the central axis of the right end face has a counterbore with the same diameter as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com