Method for determining aromatic bead positional deviation in aromatic bead filter sticks

A technology of fragrant beads filter rod and measurement method, which is applied in the direction of using microwave flaw detection, etc., can solve the problems of fragrant beads moving, falling, and inability to accurately measure the original position, so as to reduce loss, realize automatic batch detection, and realize automatic batch processing of data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] like Figure 1 ~ Figure 2 Shown, a kind of measuring method of fragrance bead position deviation in the fragrance bead filter stick, its method is as follows:

[0032] A. Selection of fragrant bead filter stick: choose a fragrant bead filter stick with a length of 120mm, which includes four cigarette filter tips, each of which contains a fragrant bead;

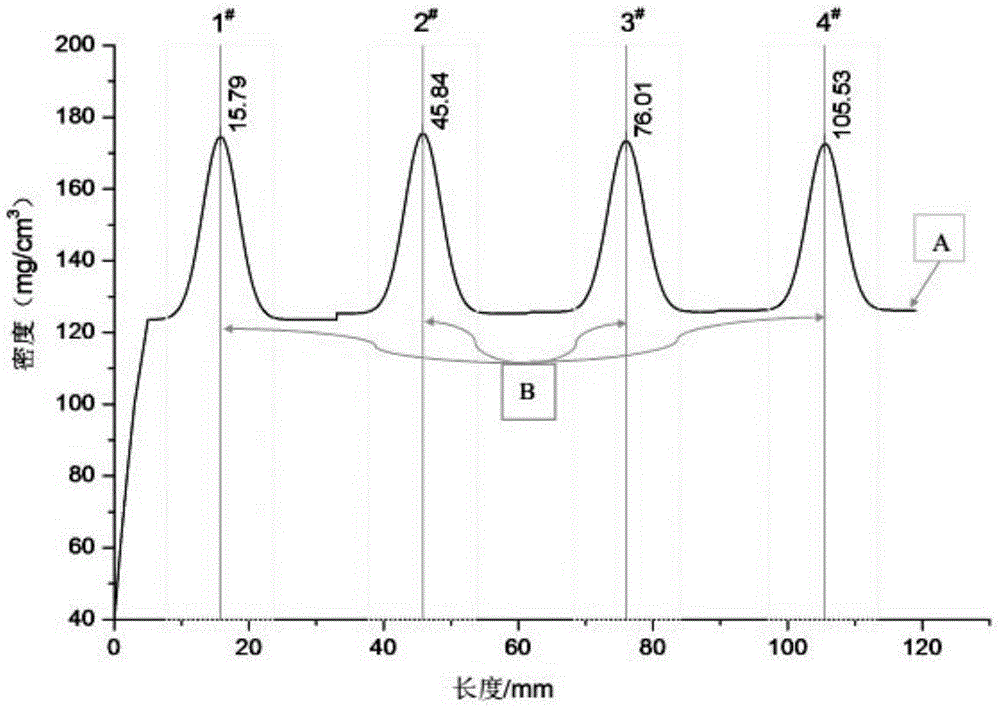

[0033] B. Acquisition of density distribution of fragrant bead filter rods: Set transverse density collection points at intervals of Xmm in the length direction of fragrant bead filter rods, where X is 0.1 to 1.5mm; obtain the density at each interval of Xmm through a cigarette microwave density measuring instrument Transverse density value, collect all the transverse density values of the fragrant bead filter rod in the length direction;

[0034] C. Construct the density value distribution curve of the fragrant bead filter rod: the cigarette microwave density measuring instrument takes the length value data of the f...

Embodiment 1

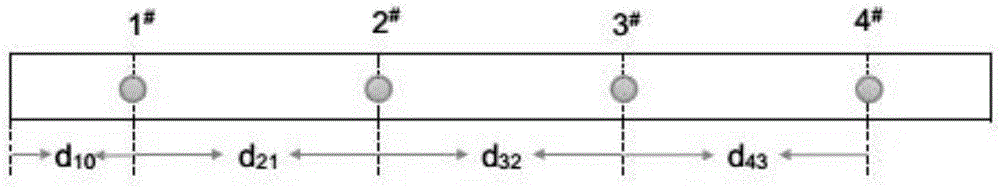

[0051] like figure 1 Said, with a length of 120mm contains 4 incense beads (respectively numbered 1 # ,2 # 、3 # 、4 # ) scented bead filter stick is an example of the detection object (see the schematic diagram of the scented bead filter stick in the accompanying drawing figure 1 ), the design requirement of the fragrance beads in the fragrance bead filter rod is that the distance from the first fragrance bead to the beginning of the fragrance bead filter rod is d 10 =15±1mm, the distance from the second fragrance bead to the first fragrance bead is d 21 =30±2mm, the distance from the third fragrance bead to the second fragrance bead is d 32 =30±2mm, the distance from the 4th fragrance bead to the 3rd fragrance bead is d 43 =30±2mm.

[0052] Step 1. Collection of axial density distribution of fragrant bead filter rods:

[0053] Prepare 10 samples of the above fragrant bead filter rods, and measure the density values of 10 fragrant bead filter rods at an interval of 1m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com