Method for predicting maximum height of filling mining diversion fissure zone

A water-conducting fracture zone and maximum height technology, applied in the direction of prediction, instrumentation, data processing applications, etc., can solve the problems of complex underground stope stress and difficulty in finding the corresponding relationship accurately, and achieve high accuracy, easy observation, and method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

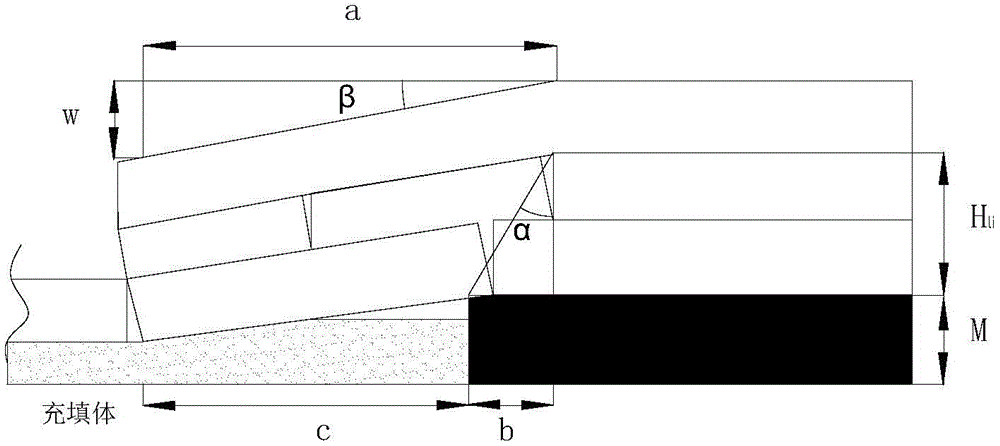

[0077] Based on the Taiping Coal Mine, the development height of the water-conducting fracture zone in the filling mining of the 8305 working face of the Taiping Mine is predicted. The overlying strata of the 8305 working face are fine sandstone and mudstone, mainly fine sandstone.

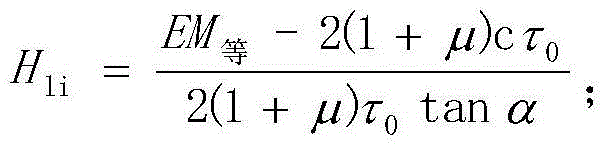

[0078] According to the actual measurement data of Taiping Mine, the elastic modulus E is taken as 10.25Gp, the shear strength τ0 is taken as 36.12MPa, Poisson’s ratio μ is taken as 0.216, and the equivalent mining thickness of filling mining is M 等 is 0.43m, the fracture angle α is 70°, and the periodic pressure step distance c is 30m. Substituting it into the calculation formula for the maximum height of the water-conducting fracture zone in filling mining, the maximum height of the filling mining water-conducting fracture zone is calculated to be 7.34m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com