Quality evaluation method for polycrystalline silicon ingot

A technology for polycrystalline silicon ingots and determination methods, applied in data processing applications, resources, calculations, etc., can solve problems such as inaccurate determination, passive production of polycrystalline silicon ingots, and failure to consider the influence of crystal growth morphology quality, etc., to achieve grade reliability , the effect of reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

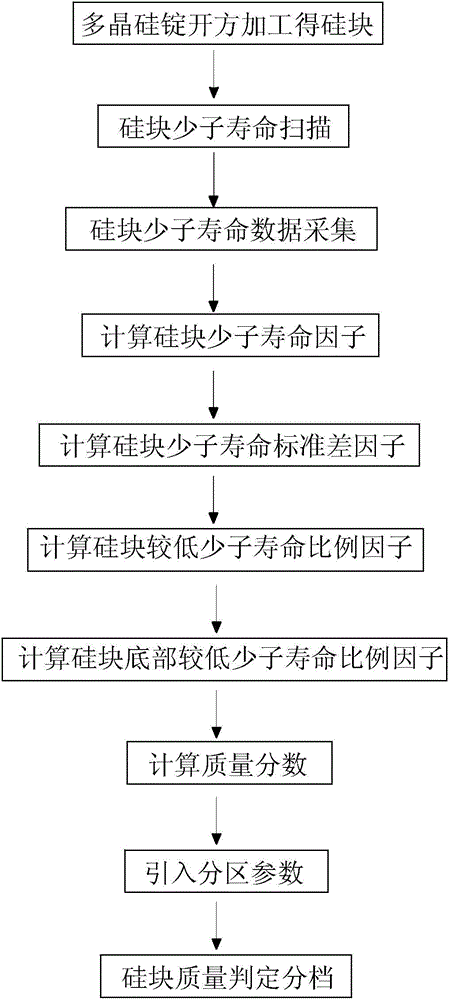

[0026] A method for judging the quality of polycrystalline silicon ingots, comprising the following steps:

[0027] (1) The polycrystalline silicon ingot is processed according to the standard size requirements, and squared into polycrystalline small square ingots containing different partitions such as the middle, side and corner of the polycrystalline silicon ingot, that is, silicon blocks.

[0028] (2) Use the Semilab WT2000 series microwave photoconductive attenuation quantum lifetime detection instrument to scan the silicon block in the middle of the polycrystalline silicon ingot for the minority carrier lifetime, set the scanning grating to 2mm, the sensitivity to 50mV, the size of the silicon block to 8 inches, and the probe scanning height to 2mm. The frequency is based on the Auto setting value.

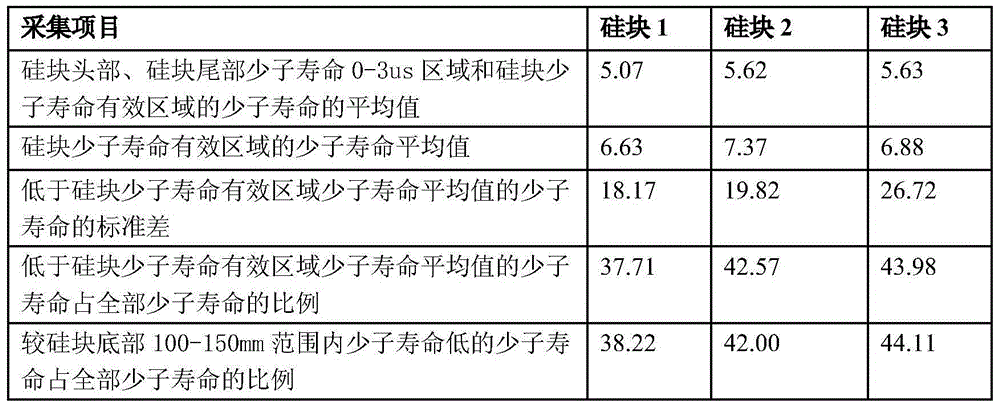

[0029] (3) Collect and process the scanning data according to the following calculations to obtain the minority carrier lifetime factor X1, the standard deviation factor X2 ...

Embodiment 2

[0043] A method for judging the quality of polycrystalline silicon ingots, comprising the following steps:

[0044] (1) The polysilicon ingot is processed according to the standard size requirements, and squared into silicon blocks containing different partitions such as the middle part, the side part and the corner part of the polysilicon ingot.

[0045] (2) Use the Semilab WT2000 series microwave photoconductive attenuation quantum lifetime testing instrument to scan the minority carrier lifetime of the silicon block at the edge of the polysilicon ingot, set the scanning grating to 4mm, the sensitivity to 100mV, the silicon block size to 8 inches, and the probe scanning height to 2.5mm. The frequency is based on the Auto setting value.

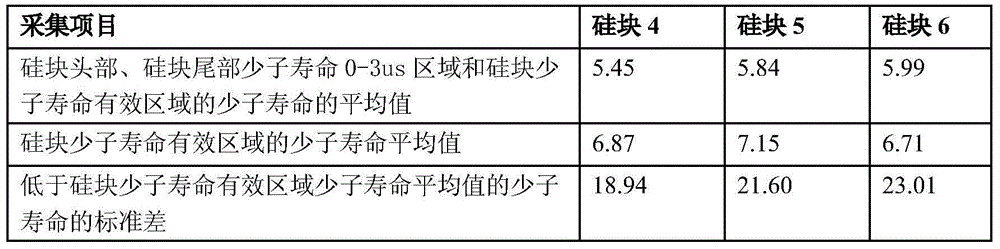

[0046] (3) Collect and process the scanning data according to the following calculations to obtain the minority carrier lifetime factor X1, the standard deviation factor X2 of the minority carrier lifetime of the silicon block, the proportio...

Embodiment 3

[0061] A method for judging the quality of polycrystalline silicon ingots, comprising the following steps:

[0062] (1) The polysilicon ingot is processed according to the standard size requirements, and squared into silicon blocks containing different partitions such as the middle part, the side part and the corner part of the polysilicon ingot.

[0063] (2) Use the Semilab WT2000 series microwave photoconductive attenuation quantum lifetime testing instrument to scan the minority carrier lifetime of the silicon block at the corner of the polysilicon ingot, set the scanning grating to 2mm, the sensitivity to 80mV, the size of the silicon block to 8 inches, and the scanning height of the probe to 1.5mm. The frequency is based on the Auto setting value.

[0064] (3) Collect and process the scanning data according to the following calculations to obtain the minority carrier lifetime factor X1, the standard deviation factor X2 of the minority carrier lifetime of the silicon block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com