Suction disc separation mechanism for lead storage battery plate

A lead-acid battery and separation mechanism technology, which is applied in the field of mechanical parts, can solve the problems of poor separation effect and low stability of the plates, and achieve the effects of improving stability, preventing dumping, and improving separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

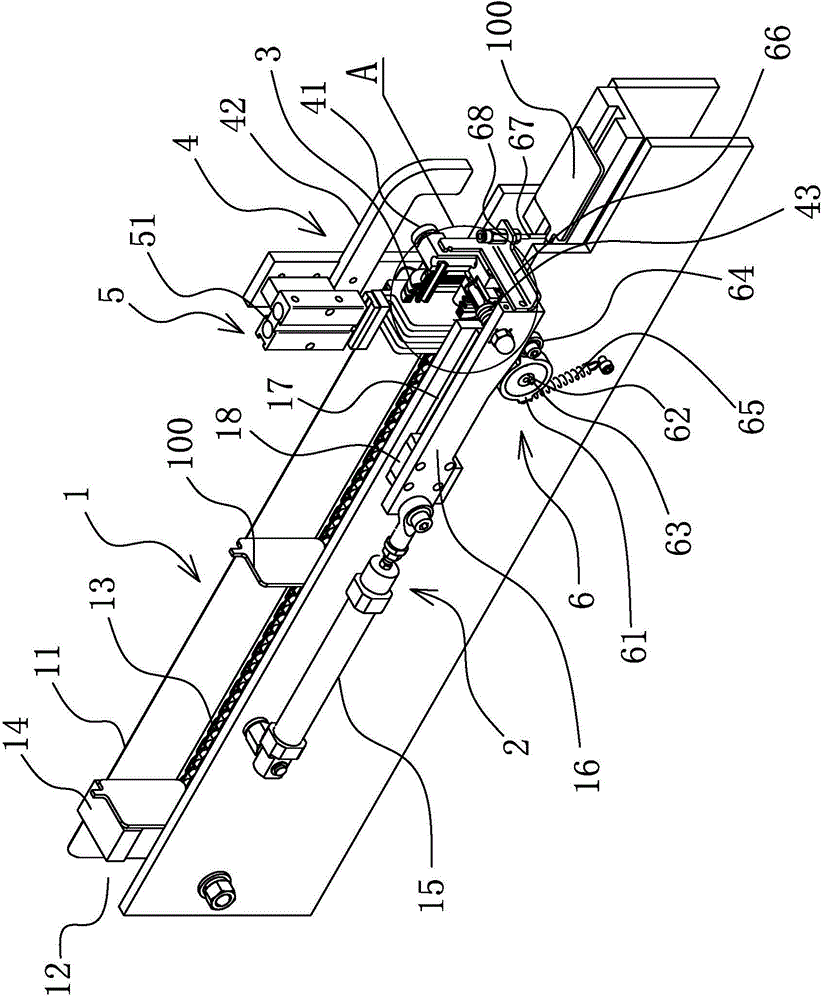

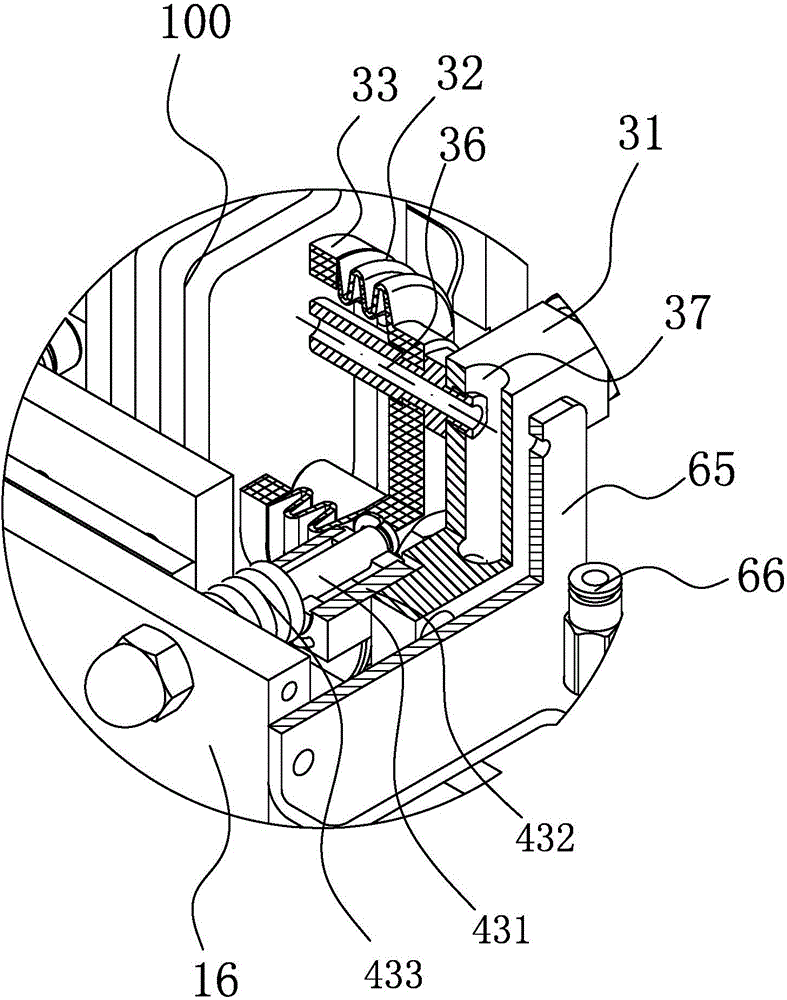

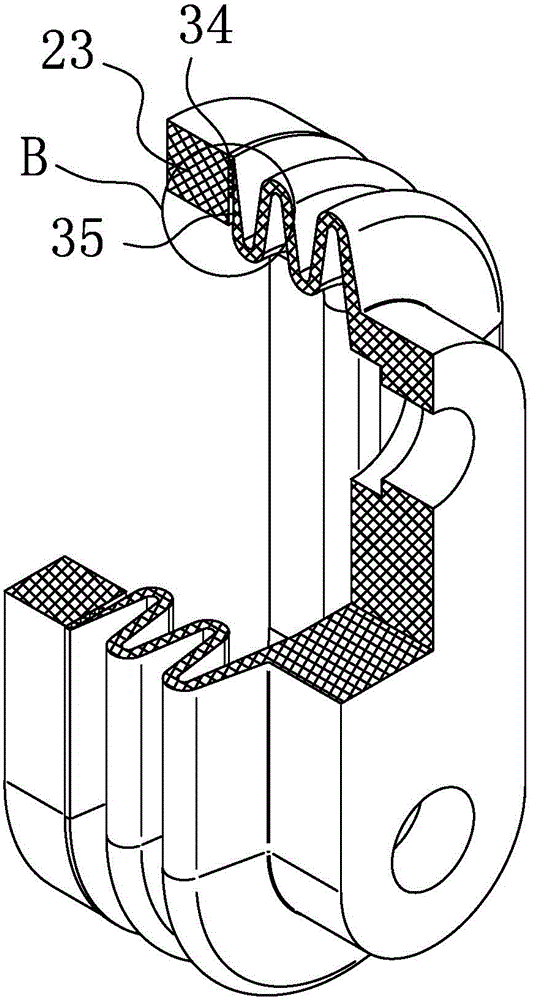

[0025] Such as Figure 1-5 As shown, a lead-acid battery plate sucker separation mechanism includes a track conveying mechanism 1 capable of transporting pole plates 100, a drive mechanism 2 is provided on the track conveying mechanism 1, and the end of the drive mechanism 2 is provided with There is a suction cup mechanism 3 that can hold and loosen the inner pole plate 100 of the rail conveying mechanism 1. The driving mechanism 2 can push the sucker mechanism 3 to move back and forth. Suction cup turning mechanism4. When working, the pole plate 100 is placed in the track conveying mechanism 1 and sent to the position where the suction cup mechanism 3 is located. The suction cup mechanism 3 is connected to a vacuum device and a compressed gas device through a pipeline. The mechanism 3 is connected to the vacuum device to suck the pole plate 100. At this time, the driving mechanism 2 pushes the suction cup mechanism 3 to move forward. When the suction cup mechanism 3 contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com