Crusher used for nodulizing agent

A crusher and spheroidizing agent technology, which is applied in grain processing, etc., can solve the problems of low crushing efficiency of spheroidizing agent and substandard crushing effect, and achieve convenient feeding and discharging, low noise, and improved crushing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0021] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

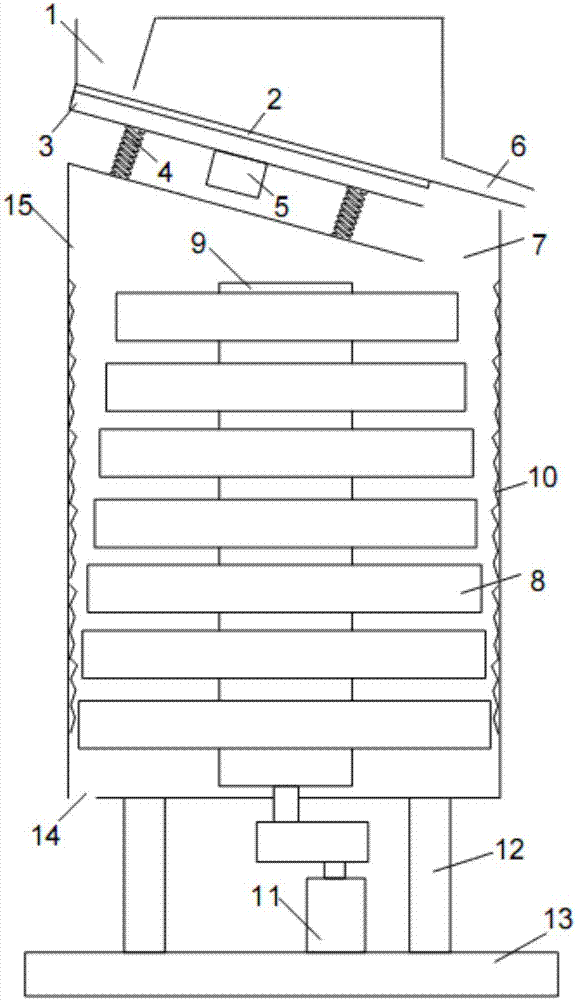

[0022] Such as figure 1 Shown is an implementation form according to the invention, which includes:

[0023] The body 15 has a cylindrical cavity structure and is vertically arranged on the ground. The upper end surface of the body 15 is arranged obliquely downward, and a blanking opening 7 is provided at the lower part of the upper end surface; Placed on the upper end of the machine body, at a certain distance from the upper end surface, and in the same direction as its inclination, the screen 2 is used for primary screening of the incoming materials, and the qualified nodulari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com