Rapid grounding rod with plugging device, suitable for temporary opeartion

A technology of plug-in device and grounding rod, which is applied in the direction of connecting contact materials, etc., can solve the problems of affecting timeliness, difficulty in pulling out, and increase in resistance value, and achieves the advantages of easy disassembly and installation, improved protection effect, and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

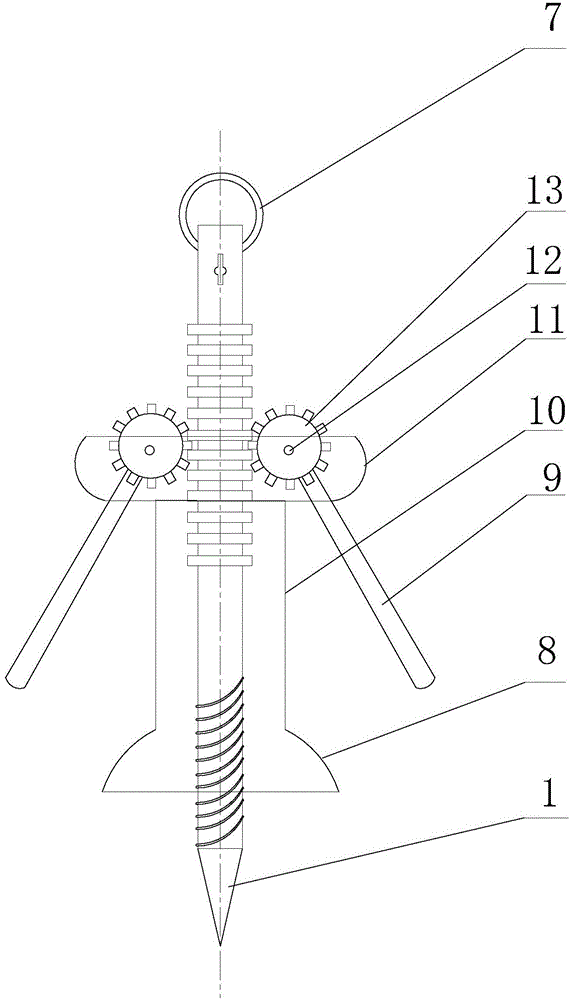

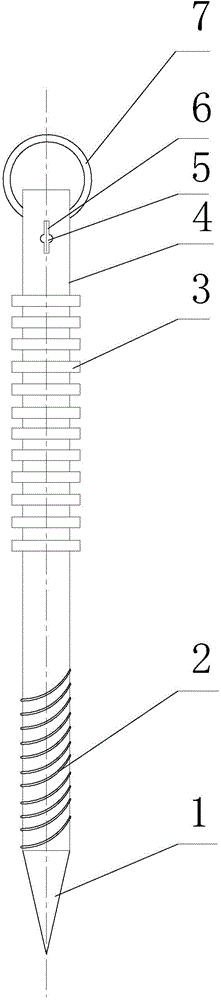

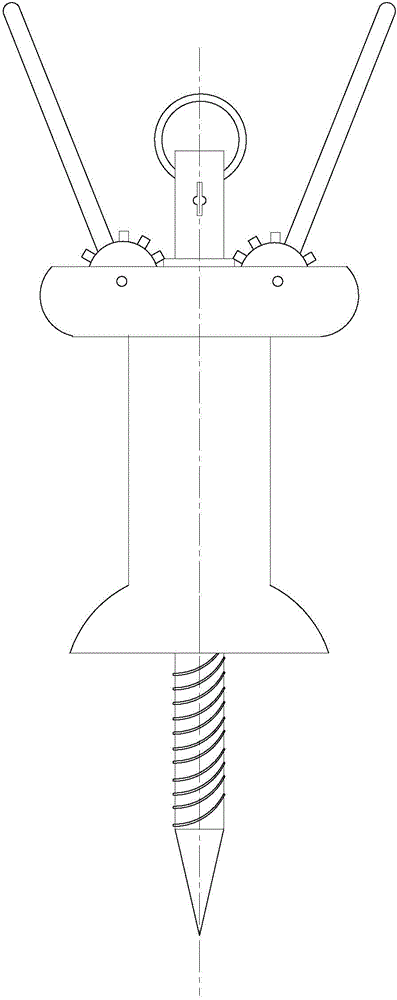

[0018] Depend on Figure 1 to Figure 4 As shown, this kind of fast grounding rod with its own plug-in device suitable for temporary operations includes a rod-shaped grounding rod body 4, which is unique in that: the bottom end of the grounding rod body 4 is a cone segment 1, and the Above the cone section 1 is an externally threaded section 2, and the top of the ground rod main body 4 is provided with a threading groove 6 through which a nickel sealing hole 5 is opened in the middle section of the threading groove. Above the threading groove, a hard insulating ring 7 is fixed through the main body of the grounding rod; on the main body of the grounding rod, it is fixed at equal intervals between the lower part of the threading groove and the upper part of the external thread section 2 There are several nested ring bodies 3, the longitudinal section of the convex part of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap