Light irradiation device for curing and method of manufacturing electric wire module including connection part

An irradiation device and light irradiation technology, applied in the direction of line/collector parts, circuits, connections, etc., can solve the problem of insufficient curing of waterproofing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the method of manufacturing the light irradiation device for curing and the wire module including the connection portion according to the embodiment will be described.

[0050] (Waterproof intermediate connection part of electric wire)

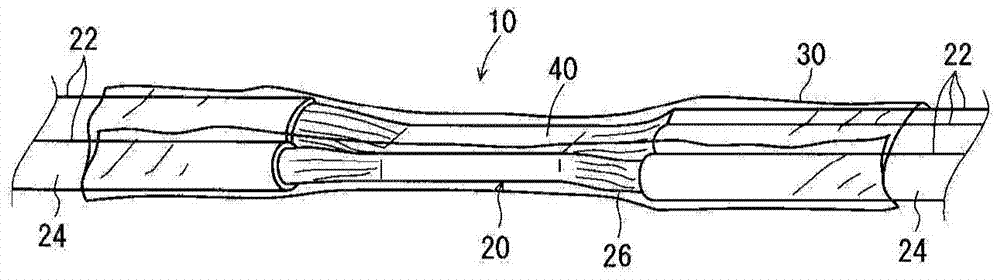

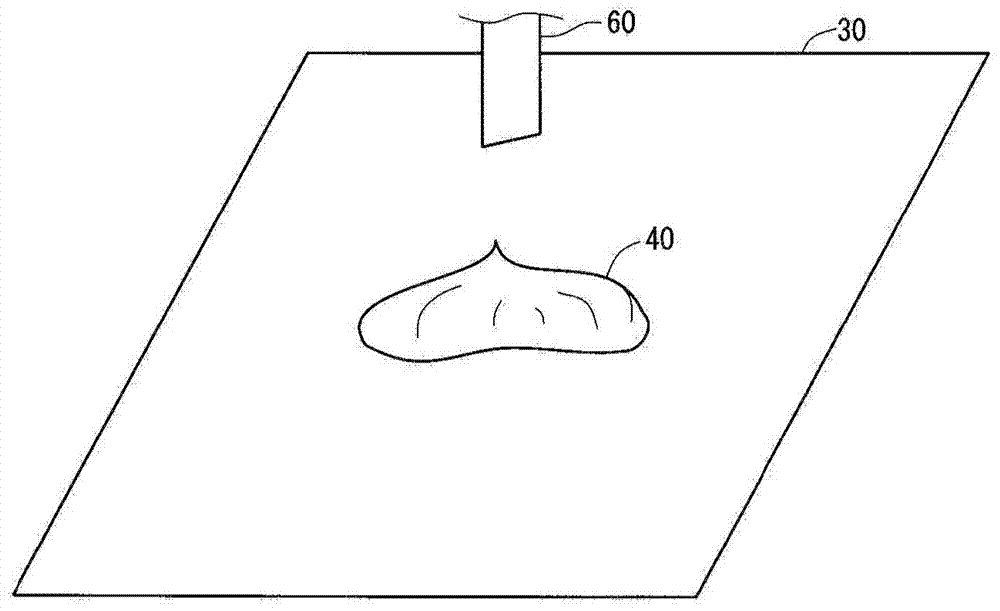

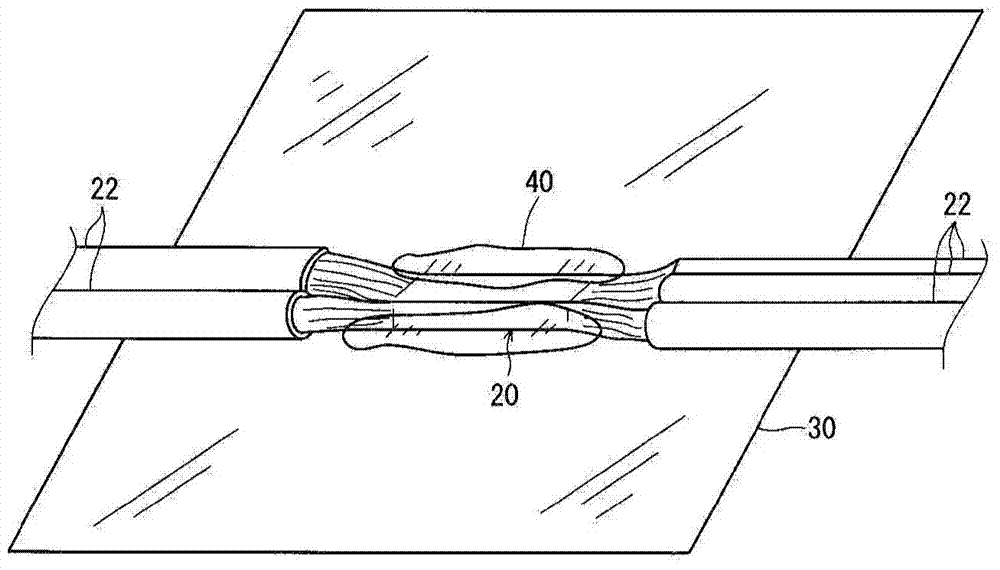

[0051] The wire module 10 including the connection portion 20 will be described. figure 1 It is a schematic perspective view showing the wire module 10 including the connection portion 20 .

[0052] This electric wire module 10 includes a plurality of electric wires 22 , a connection portion 20 , a waterproofing agent 40 , and a sheet 30 .

[0053] The electric wire 22 includes a core wire portion 26 and a covering portion 24 covering the periphery of the core wire portion 26 . The covering part 24 is formed by extruding and covering the periphery of the core wire part 26 with an insulating resin.

[0054] The connection portion 20 is a portion where the core portion 26 is exposed by partially removing the covering porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com