Small tension stringing device

A tension stringing and reel technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of complex operation of tension stringing devices, many links to control tension, and failure to operate normally, so as to achieve low difficulty in guide height adjustment and smooth operation. The effect of uniformity and reducing the workload of height guide adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

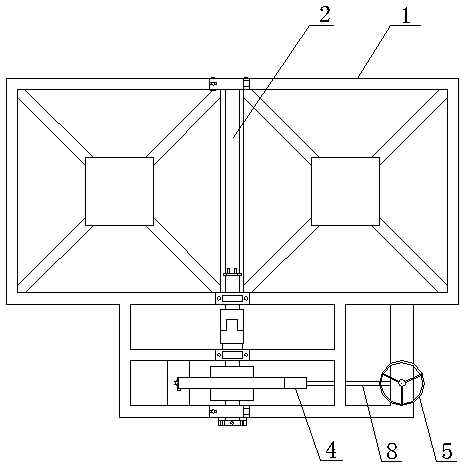

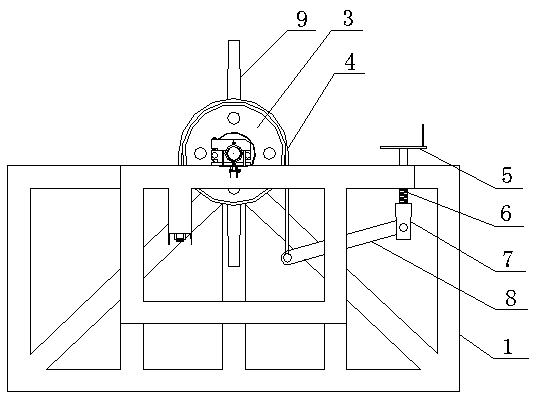

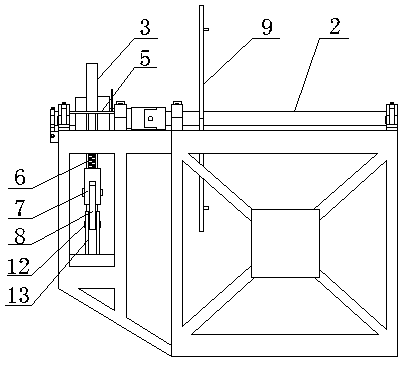

[0015] As shown in the figure, the small tension wire racking device is provided with a wire reel frame 1 for carrying wire reels. The wire reel frame 1 is a frame formed by connecting channel steel to support other components. A bearing spool 2 and a tension adjustment mechanism are provided. The bearing spool 2 is rotatably arranged on the spool frame 1, and is inserted into the spool hole to drive the spool to rotate. The bearing spool 2 is arranged horizontally, and its two ends are detachably set to the spool. On the frame on both sides of the top of the rack 1, when the spool is installed, remove the bearing spool 2, insert it into the center hole of the spool, install the spool on the bearing spool 2, and install the fixing rod on the bearing spool 2 perpendicular to its axial direction 9. It is clamped on one side of the spool, and the other side of the spool is clamped by the clamp set on the carrying spool 2 to avoid the spool from swinging left and right during the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com