Rotor structure of surface-mounted high-speed permanent magnet motor

A rotor structure, permanent magnet motor technology, applied in the magnetic circuit shape/pattern/structure, magnetic circuit rotating parts and other directions, can solve the problems of poor gas flow characteristics, increased initial rotor imbalance, etc., to achieve enhanced flow, good Initial balance, effect of increasing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

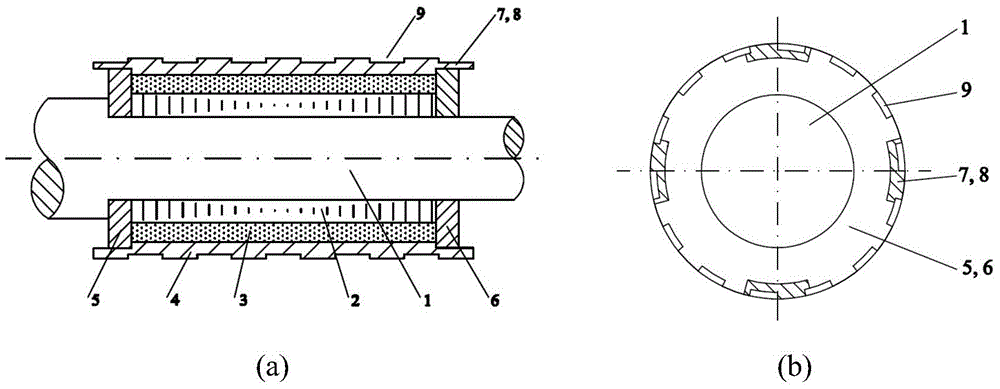

[0018] Such as figure 1 As shown, it includes a rotating shaft 1, a rotor core 2, a permanent magnet 3, a protective sleeve 4, a left end flange 5 and a right end flange 6. The two ends of the protective sleeve 4 are circumferentially symmetrically distributed with a plurality of keys 7 beyond the outer end surfaces of the left flange 5 and the right flange 6, and the left flange 5 and the right flange 6 also have keys at both ends of the protective sleeve 4. 7, the outer surface of the protective sheath 4 is evenly distributed in the circumferential direction with a plurality of grooves 9 that form a certain angle with the busbar of the protective sheath 4. The rotor core 2, the left flange 5 and the right flange 6 are set on the rotating shaft 1, and the steps on the left side of the shaft are used for axial positioning, and the permanent magnet 3 is set on the rotor core between the left flange 5 and the right flange 6 On the outer circle of 2, protective cover 4 is enclos...

Embodiment 2

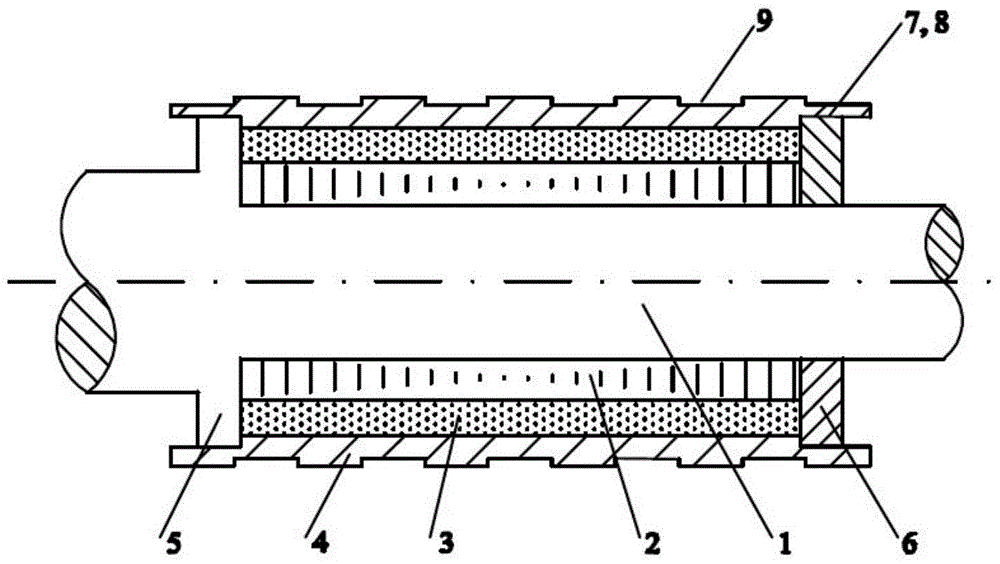

[0022] Such as figure 2 As shown, it includes rotating shaft 1, rotor core 2, permanent magnet 3, protective cover 4, left end flange 5 and right end flange 6, and a step is designed at the left end of the installation position of rotor iron core 2 to form left end flange 5. The two ends of the protective sleeve 4 are circumferentially symmetrically distributed with a plurality of keys 7 beyond the outer end surfaces of the left flange 5 and the right flange 6, and the left flange 5 and the right flange 6 are also designed with keys at both ends of the protective sleeve 4. 7, the outer surface of the protective sheath 4 is evenly distributed in the circumferential direction with a plurality of grooves 9 that form a certain angle with the busbar of the protective sheath 4.

[0023] When installing, first put the rotor core 2 on the rotating shaft 1, and use the left end flange 5 on the shaft for axial positioning. On the outer circle of the rotor core 2 with 3 permanent magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com